Operation of photolithography process

A technology of photolithography process and photoresist layer, applied in the field of photolithography process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

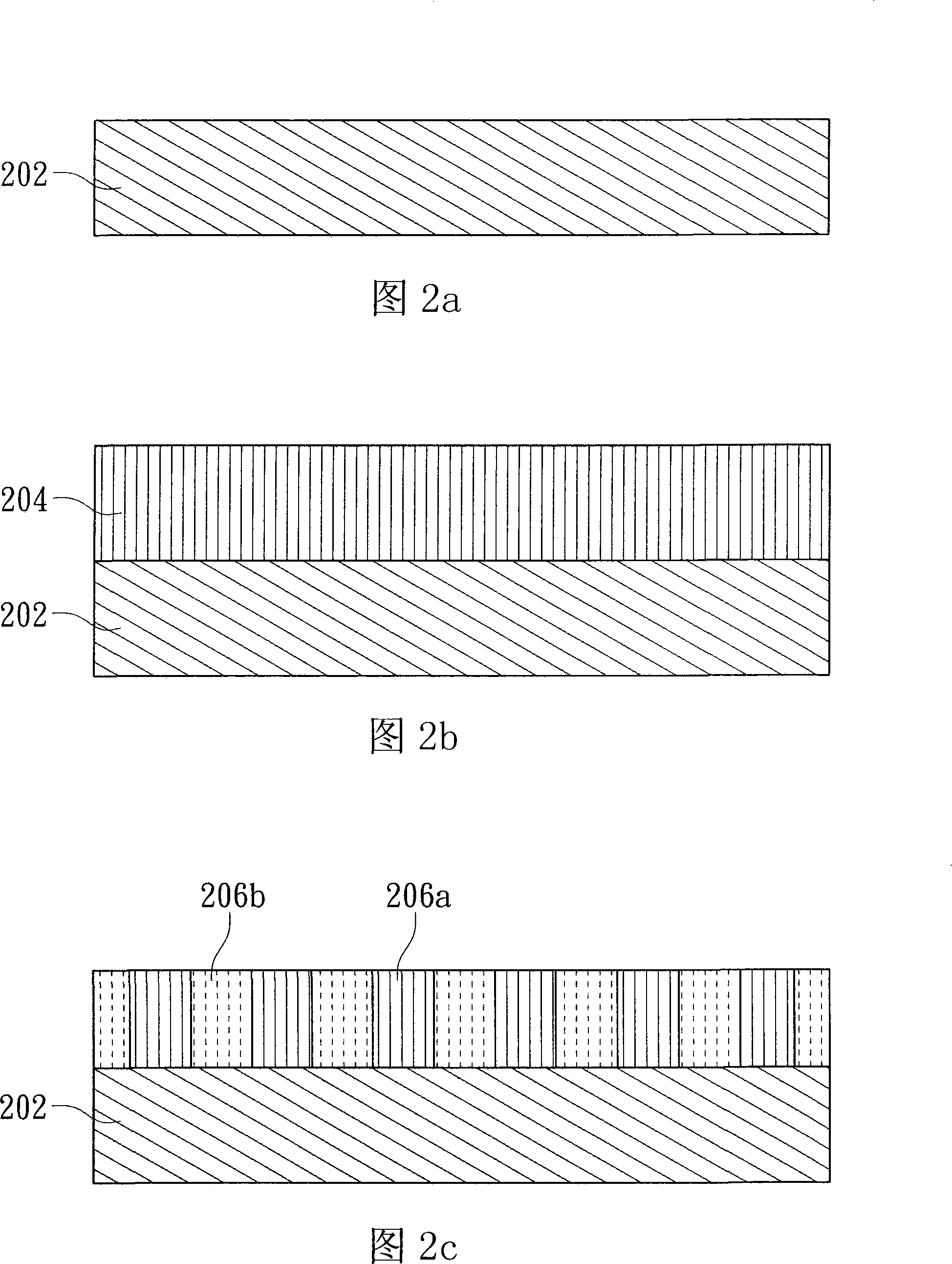

[0028] Step 104 of method 100 is to deposit photoresist on the substrate. refer to Figure 2b , a layer of photoresist 204 is deposited on the substrate 202 . The substrate 202 may include multiple layers of thin films, such as a thin film stack. Photoresist 204 may comprise a conventional photoresist layer and may be deposited on substrate 202 by conventional methods, such as spin-on coating. According to one embodiment of the present invention, the photoresist 204 comprises a conventionally acceptable 193nm photoresist material.

[0029] In step 106, an exposure operation and a post-exposure baking process are performed. refer to Figure 2c , the photoresist 204 is patterned to include exposed photoresist portions 206b and unexposed photoresist portions 206a. It should be understood that different photoresist materials can be used, and a positive photoresist is used as an example for illustration. The exposure system and the baking system may be separate systems.

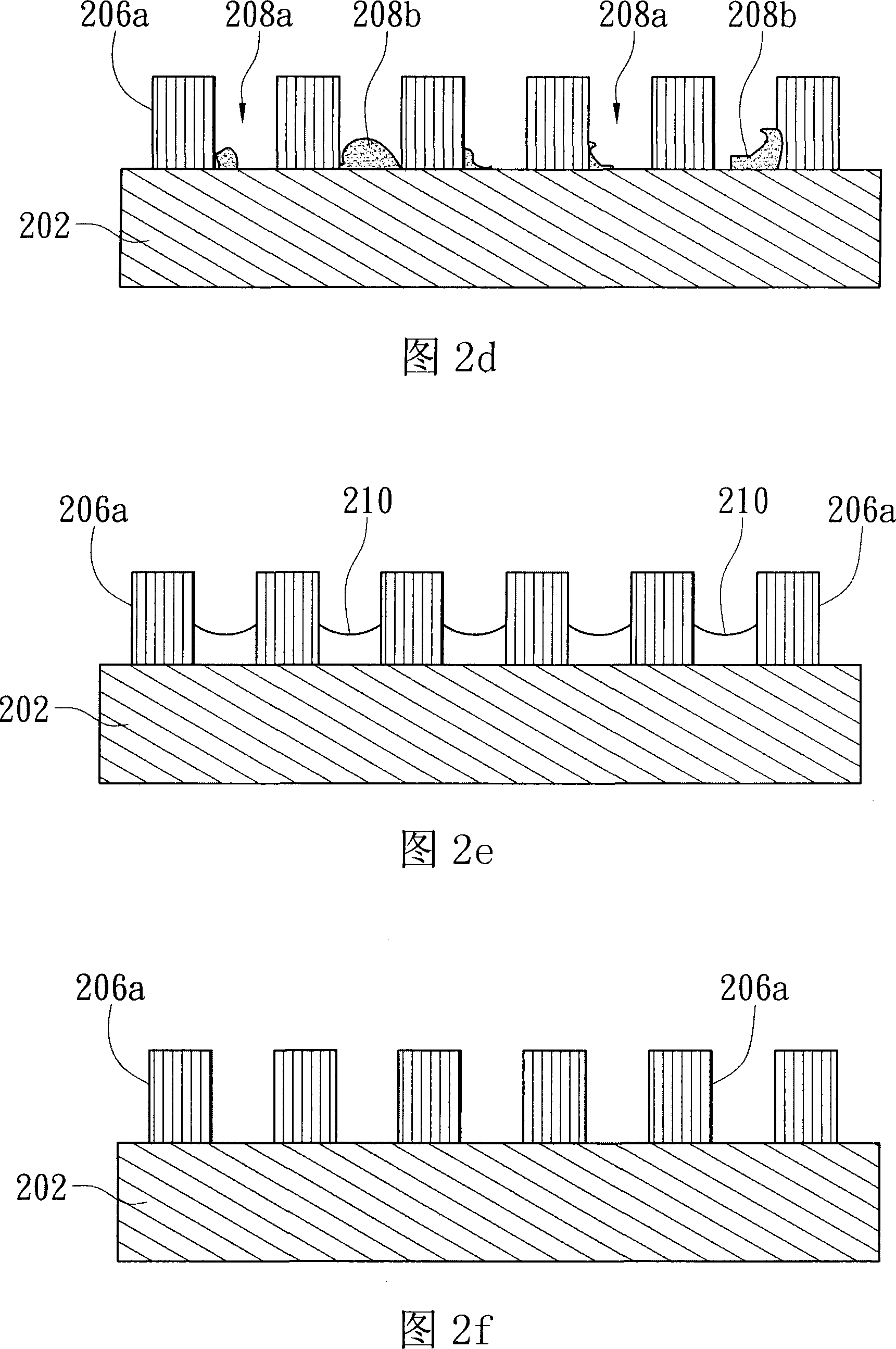

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com