Process for production of fuel cell separators and fuel cells

A fuel cell and manufacturing method technology, applied to fuel cell parts, fuel cells, solid electrolyte fuel cells, etc., can solve problems such as inability to discharge smoothly, water retention, reduction in electromotive force, etc., and achieve stable electromotive force and excellent discharge performance. , the effect of high wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

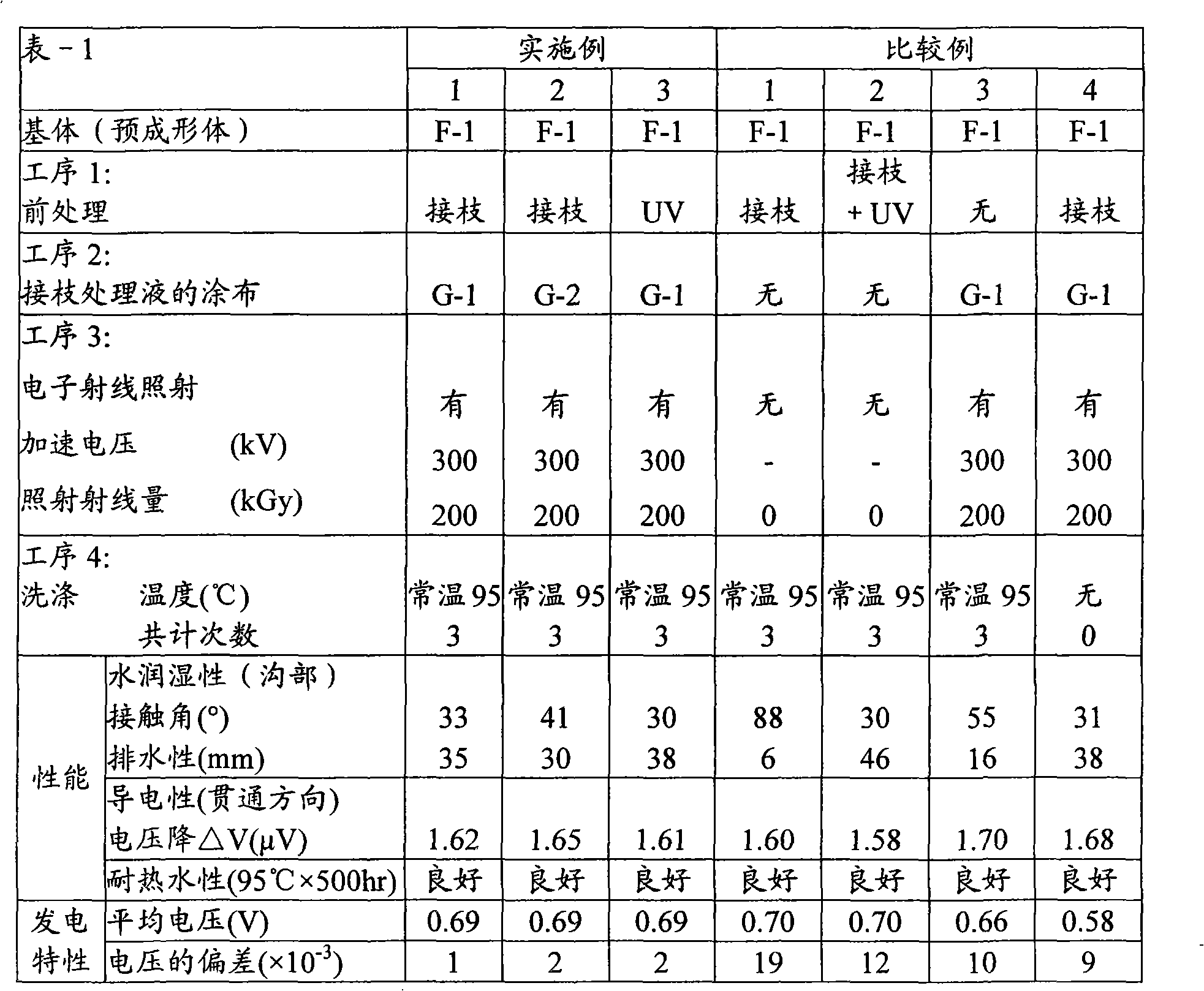

[0106] The molded product F-1 obtained in Preparation Example 2 was pretreated by blasting the electrode portion (groove portion) with a blasting device. The molded article was uniformly coated with graft treatment liquid G-1 treated with nitrogen blowing on the channel grooves of the electrode part in the atmosphere, and dried at room temperature for about 10 minutes. Then, electron beams were irradiated at room temperature in a nitrogen atmosphere at an accelerating voltage of 300 kV and an irradiation dose of 200 kGy. In order to remove unreacted components, it was washed twice with ion-exchanged water at room temperature, and then warmly washed with ion-exchanged water at 95° C. for 3 hours. Finally, after washing with ion-exchanged water at room temperature, it was dried at room temperature for 24 hours. In this way, fuel cell separator H-1 was obtained. The separator was evaluated for water wettability, electrical conductivity, and hot water resistance of the flow chan...

Embodiment 2

[0108] The same operation as in Example 1 was performed except that the graft treatment liquid G-2 was used instead of the graft treatment liquid G-1. In this manner, fuel cell separator H-2 was obtained. For this separator, as in Example 1, the water wettability, electrical conductivity, and hot water resistance of the flow path grooves in the electrode portion, and the operating characteristics of the fuel cell were evaluated. The evaluation results thereof are shown in Table-1.

Embodiment 3

[0110] Instead of blasting, the same operation as in Example 1 was performed except that the surface treatment was performed for 30 minutes in a UV ozone treatment apparatus. In this manner, fuel cell separator H-3 was obtained. For this separator, also in the same manner as in Example 1, the water wettability, electrical conductivity, and hot water resistance of the electrode part flow channel grooves, and the operating characteristics of the fuel cell were evaluated. The evaluation results thereof are shown in Table-1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com