Acrylic resin composition and acrylic resin molded body

A technology of acrylic resin and composition, applied in the field of acrylic resin composition and acrylic resin molded body, can solve the problems of decreased mechanical strength, low mechanical strength, easy occurrence of fracture, crack, etc., and achieves excellent processability, excellent design, Effect of low melt viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

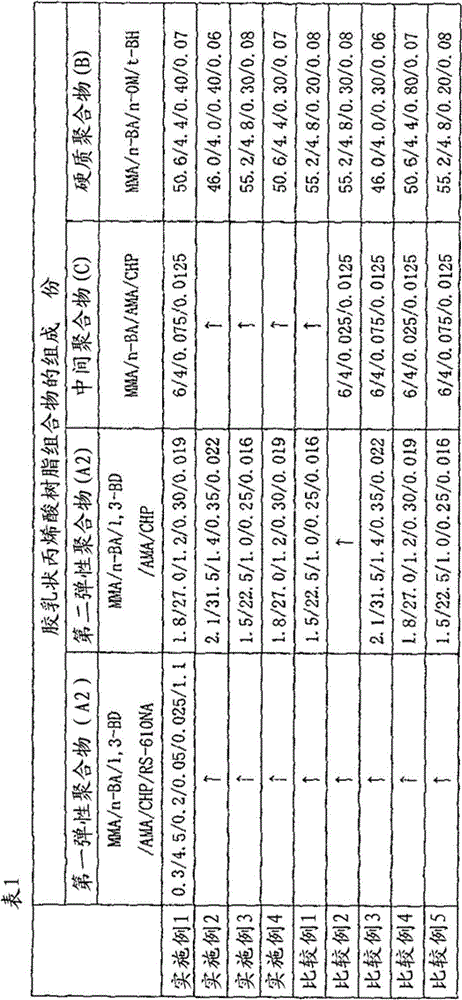

Embodiment 1

[0092] After adding 8.5 parts of deionized water to a container equipped with a mixer, add 0.3 parts of MMA, 4.5 parts of n-BA, 0.2 parts of 1,3-BD, 0.05 parts of AMA and 0.025 parts of CHP as monomer components , and stirred to mix at room temperature. Next, 1.1 parts of RS-610NA was put into the said container, stirring, and stirring was continued for 20 minutes, and the emulsion was prepared.

[0093] Next, 186.5 parts of deionized water was poured into a polymerization vessel with a cooler, and the temperature was raised to 70°C. Furthermore, a mixture prepared by adding 0.20 parts of sodium formaldehyde sulfoxylate, 0.0001 parts of ferrous sulfate, and 0.0003 parts of EDTA to 5 parts of deionized water was put into the polymerization vessel at one time. Next, the prepared emulsion was dropped into the polymerization container over 8 minutes while stirring under nitrogen, and the reaction was continued for 15 minutes to complete the polymerization of the first elastic pol...

Embodiment 2

[0113] The composition of the second elastic polymer (A2) is 2.1 parts of MMA, 31.5 parts of n-BA, 1.4 parts of 1,3-BD, 0.35 parts of AMA, 0.022 parts of CHP, and the component (B) is 46.0 MMA, 4.0 parts of n-BA, 0.40 parts of n-OM, and 0.06 parts of t-BH were carried out in the same manner as in Example 1 to prepare a film and measure its properties. The results are shown in Table 2.

[0114] The individual Tgs calculated from the first elastic polymer (A1), second elastic polymer (A2), intermediate polymer (C), and (B) components are the same as in Example 1. The average particle diameter of the latex acrylic resin composition was 0.12 μm.

Embodiment 3

[0116] The composition of the second elastic polymer (A2) is 1.5 parts of MMA, 22.5 parts of n-BA, 1.0 parts of 1,3-BD, 0.25 parts of AMA, 0.016 parts of CHP, and the component (B) is 55.2 MMA, 4.8 parts of n-BA, 0.30 parts of n-OM, and 0.08 parts of t-BH were carried out in the same manner as in Example 1 to prepare a film and measure its properties. The results are shown in Table 2.

[0117] The individual Tgs calculated from the first elastic polymer (A1), second elastic polymer (A2), intermediate polymer (C), and (B) components are the same as in Example 1. The average particle diameter of the latex acrylic resin composition was 0.12 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com