Barrel-type roller grinding device

A roller and grinding technology, which is applied in grinding/polishing equipment, metal processing equipment, and machine tools designed for grinding the rotating surface of workpieces, etc. It can solve the problem of small amount of dressing, great influence on the performance of rollers, and poor polishing consistency. Guarantee and other issues to achieve the effect of ensuring machining accuracy and production efficiency, and improving design and manufacturing levels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

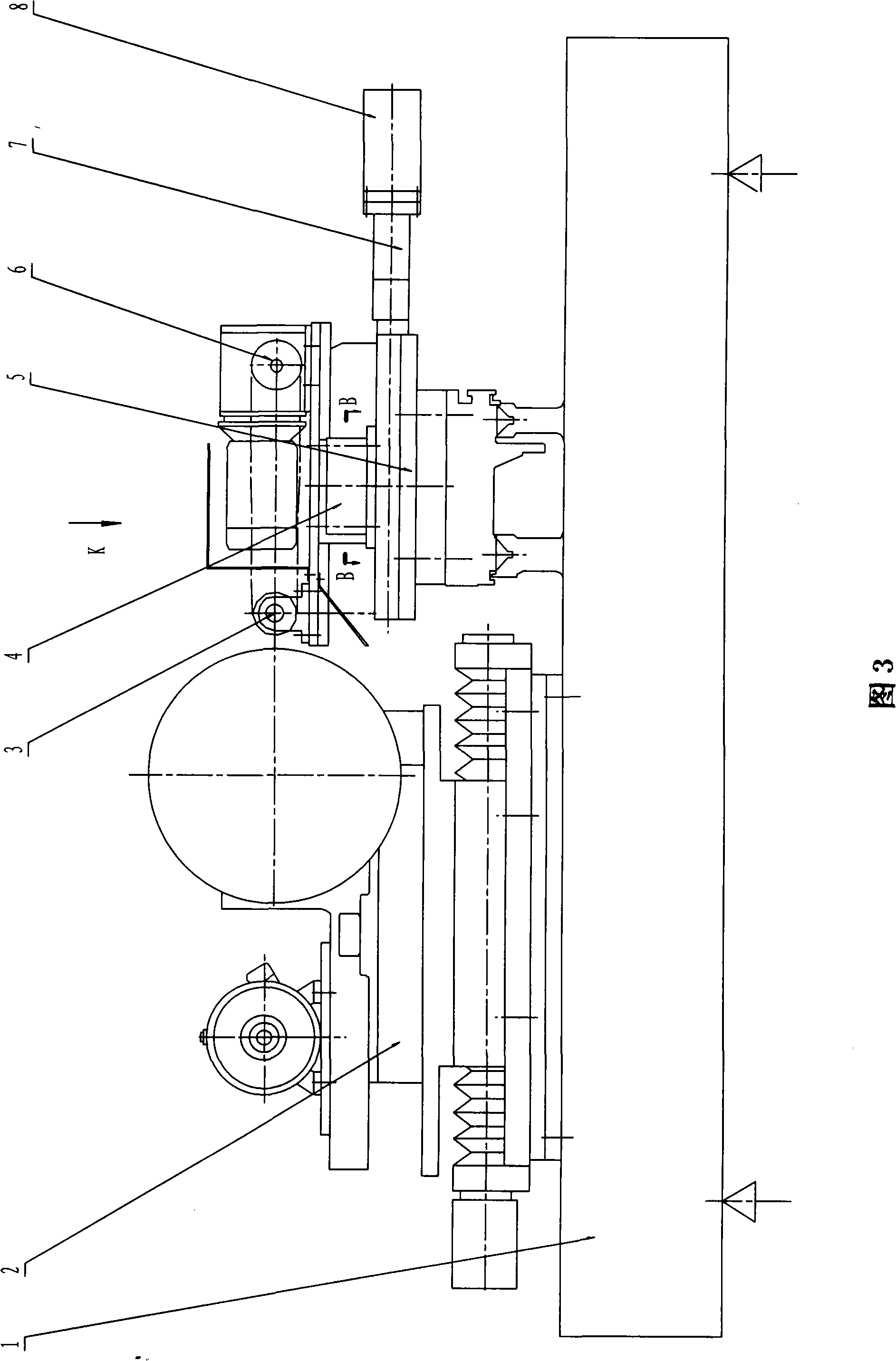

[0038] The invention includes the following components: bed, grinding wheel axis system, workpiece axis system, precision turntable components, precision linear motion components, cooling and lubrication system, control system and so on.

[0039] As shown in Figures 3 and 4, 1 is the bed, 2 is the grinding wheel shaft system, 3 is the workpiece shaft system, 4 is the precision turntable part, 5 is the precision linear motion part, 6 is the geared motor, 7 is the precision speed reduction mechanism, 8 Is a servo motor, 9 is a correction plate.

[0040] Such as Figure 5 As shown, 31 is a bearing seat, 32 is a shaft, 33 is a ribbed pulley, 34 is a duplex bearing, 35 is a flange, 36 is a workpiece, 37 is a collet, 38 is an adjustment block, and 39 is a base.

[0041] As shown in Figures 6 and 7, 41 is a spring, 42 is a base wheel, and 43 is a running wheel.

[0042] The bed is made of cast iron, and after natural failure treatment, it can ensure the overall accuracy of the mach...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap