Water absorption material and use

A technology of water-absorbing material and aqueous solution, applied in decorative arts, coated paper base paper, special art surface treatment, etc., can solve the problem of low adsorption and desalination efficiency, and achieve the effect of simple use method, good effect and fast absorption speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

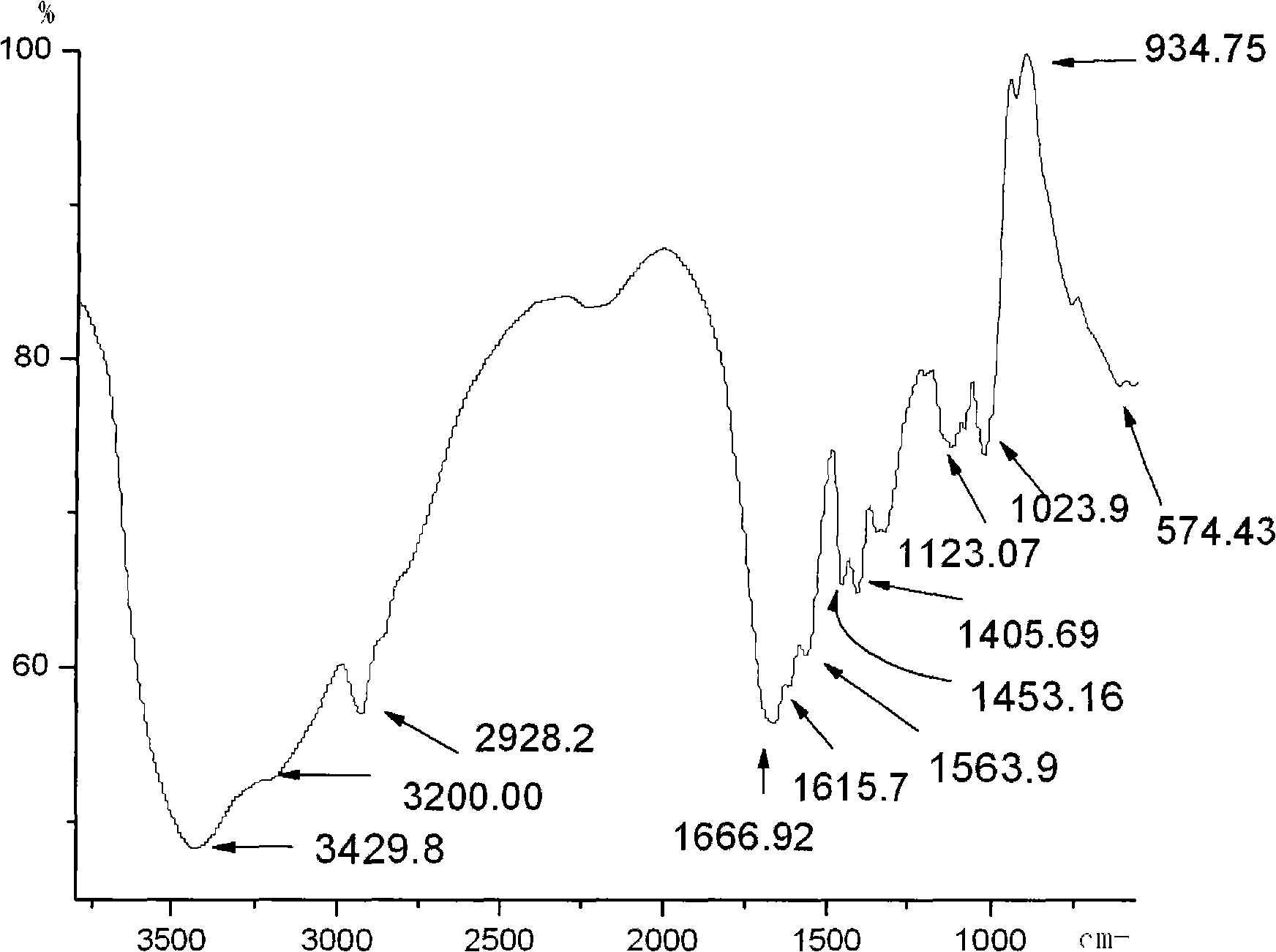

Image

Examples

Embodiment Construction

[0026] Examples of the invention are provided below.

[0027] 1: Preparation of starch grafted acrylamide resin

[0028] ① Gelatinization of starch

[0029] 5.00 grams of starch were soaked in 40 ml of distilled water for 30 minutes. Then it is heated to 80-85° C. for gelatinization under the protection of nitrogen, and the temperature is controlled for 30 minutes during the treatment. The starch polymer chain is opened through gelatinization, so that the starch can be easily contacted with the initiator, and then the free radical initiation reaction can be fully carried out.

[0030] ②Graft polymerization reaction

[0031] Cool the gelatinized starch to 50-60°C, add 0.590-0.610 grams of potassium persulfate and 0.0290-0.0310 grams of sodium sulfite solid in 40 ml of aqueous solution, and then add 10 ml of water. After initiating at 50-60°C for 15 minutes, add 280ml of aqueous solution in which 18.5-20.5 grams of acrylamide and 0.0690-0.0710 grams of cross-linking agent N,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com