Water treatment process of O3/H2O2/multiphase-fenton

A technology of H2O2 and water treatment, applied in water/sludge/sewage treatment, sterilization/microdynamic water/sewage treatment, multi-stage water/sewage treatment, etc. Seriousness and other problems, to achieve the effect of improving biodegradability, saving treatment costs, and improving oxidation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

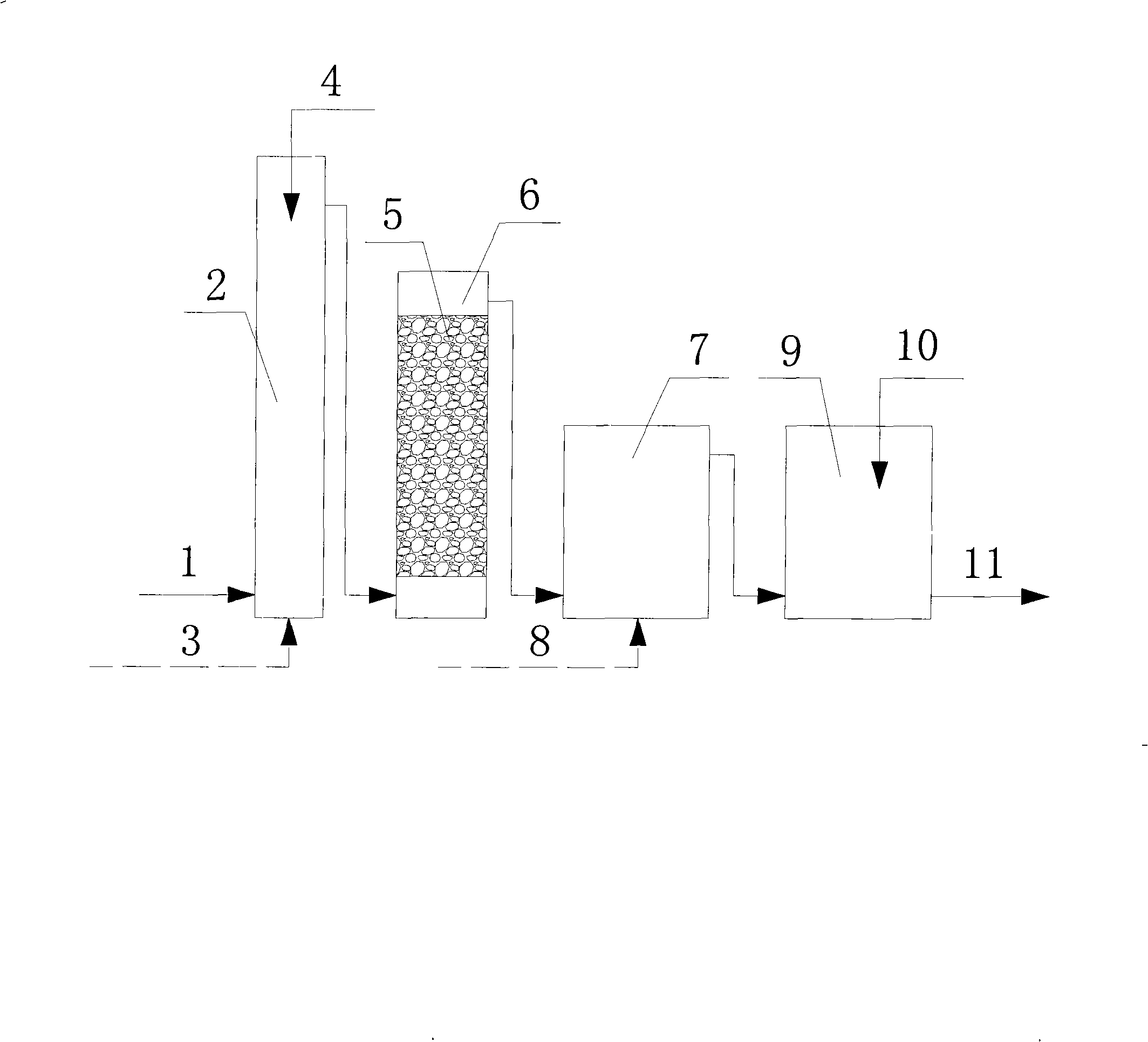

[0018] In order to ensure that the catalyst plays a good catalytic role, the oxidation reaction takes the filtered water as the treatment object. The filtered water 1 that has been treated by traditional water treatment processes such as coagulation, sedimentation, and filtration is input into the ozone contact tower 2, and the ozone oxidation reaction is carried out by passing ozone 3 into the treated water; Add hydrogen peroxide 4, carry out O 3 / H 2 o 2 Oxidation treatment; will be O 3 / H 2 o 2 The oxidized water is input into the catalyst bed 6 filled with ferric oxyhydroxide or carrier-type ferric oxyhydroxide 5 to carry out O 3 / H 2 o 2 / Heterogeneous-Fenton-like oxidation reaction; will undergo O 3 / H 2 o 2 / Multiphase-Fenton oxidized water enters the biological activated carbon filter bed 7, and carries out biological treatment under the effect of oxygen 8, which can improve the biodegradability of the treated water; enter the disinfection contact pool 9 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com