Catalytic cracking process for poor oil

A catalytic cracking and processing technology, applied in catalytic cracking, cracking, petroleum industry, etc., can solve problems such as poor oxidation safety and light safety, non-standard oil sales are not cost-effective, and catalytic diesel oil is of poor quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

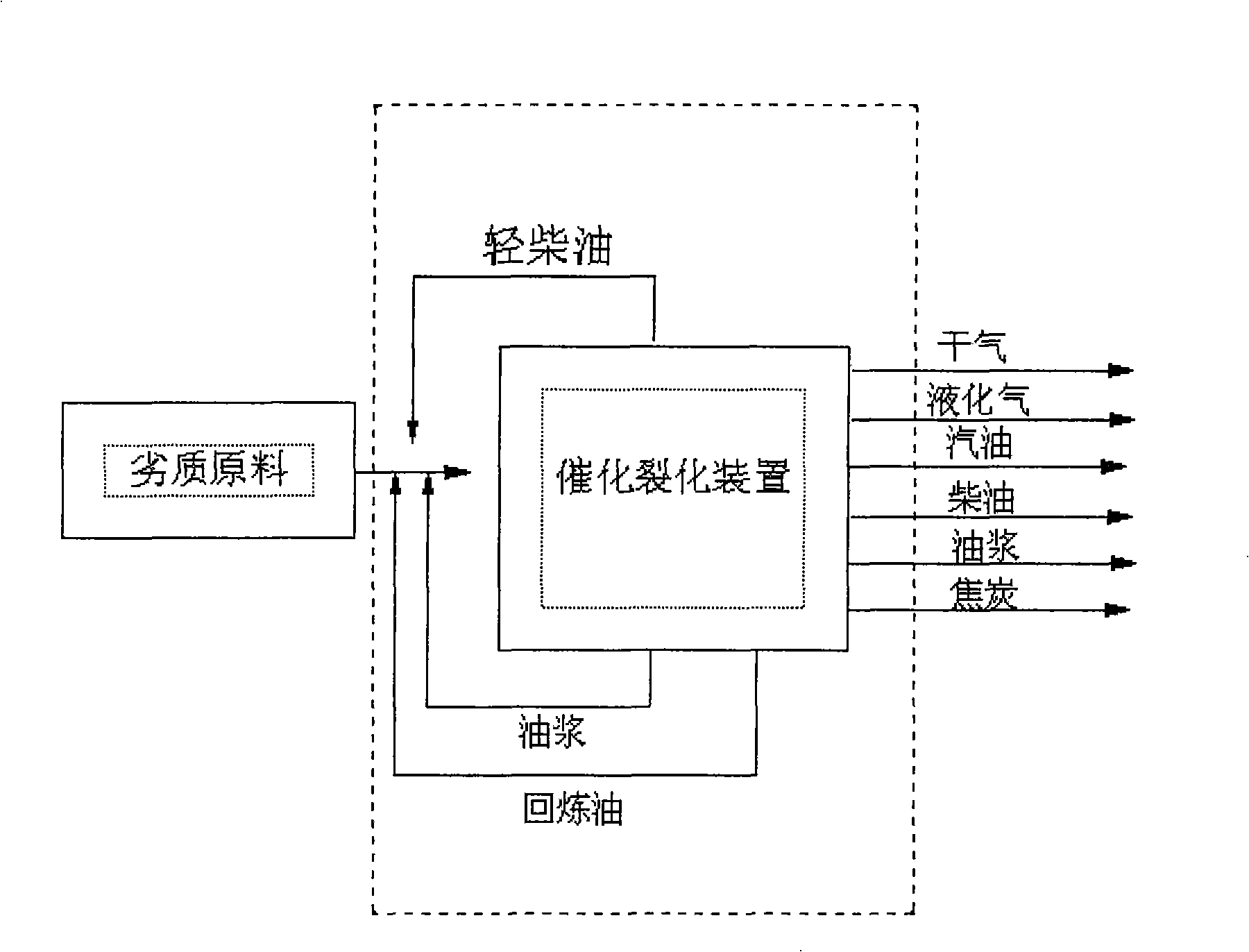

Method used

Image

Examples

Embodiment 1

[0019] Example 1 uses the same heavy oil catalytic cracking unit, inferior oil feedstock and catalyst as Comparative Example 1. The difference is that catalytic cracking diesel oil is partly re-refined, and oil slurry is partly re-refined; the total feed to the catalytic cracking unit (including fresh inferior oil raw materials, re-refined diesel oil, re-refined oil, and re-refined oil slurry) remains unchanged, and fresh raw materials are fed into The amount of material is reduced accordingly. In this example, the ratio of refined diesel oil to fresh raw material is 3:7 (weight ratio). The catalytic cracking process conditions of the embodiment are shown in Table 3, and the product distribution data and product property data are also listed in Table 4.

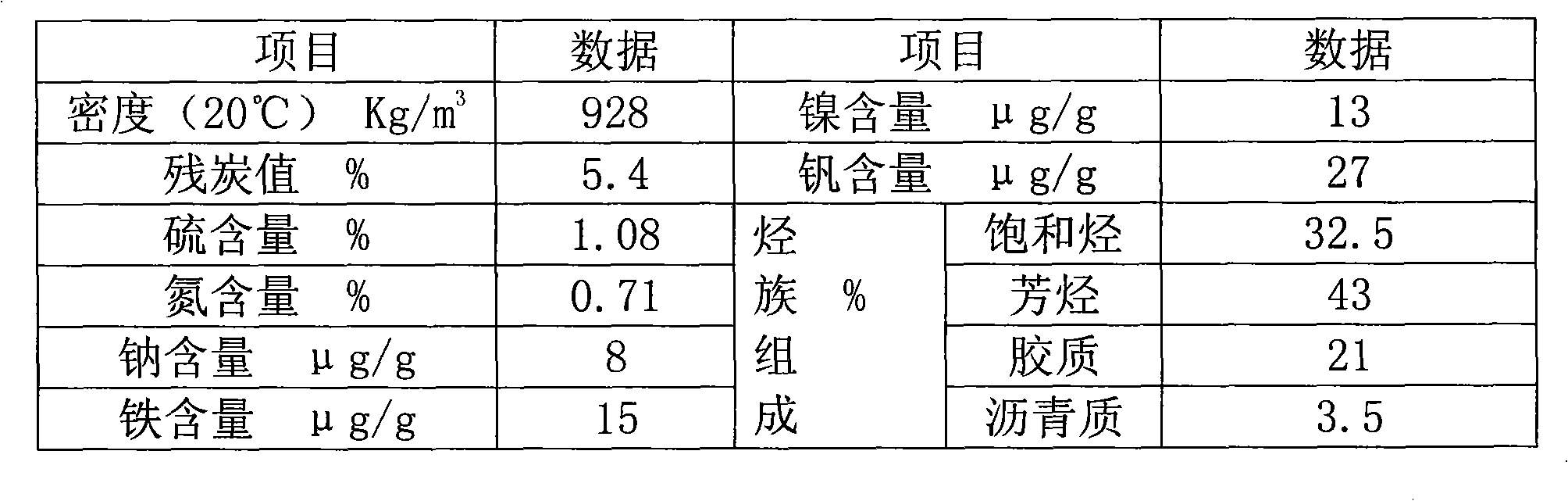

[0020] Table 1 Physicochemical properties of M100 fuel heavy oil

[0021]

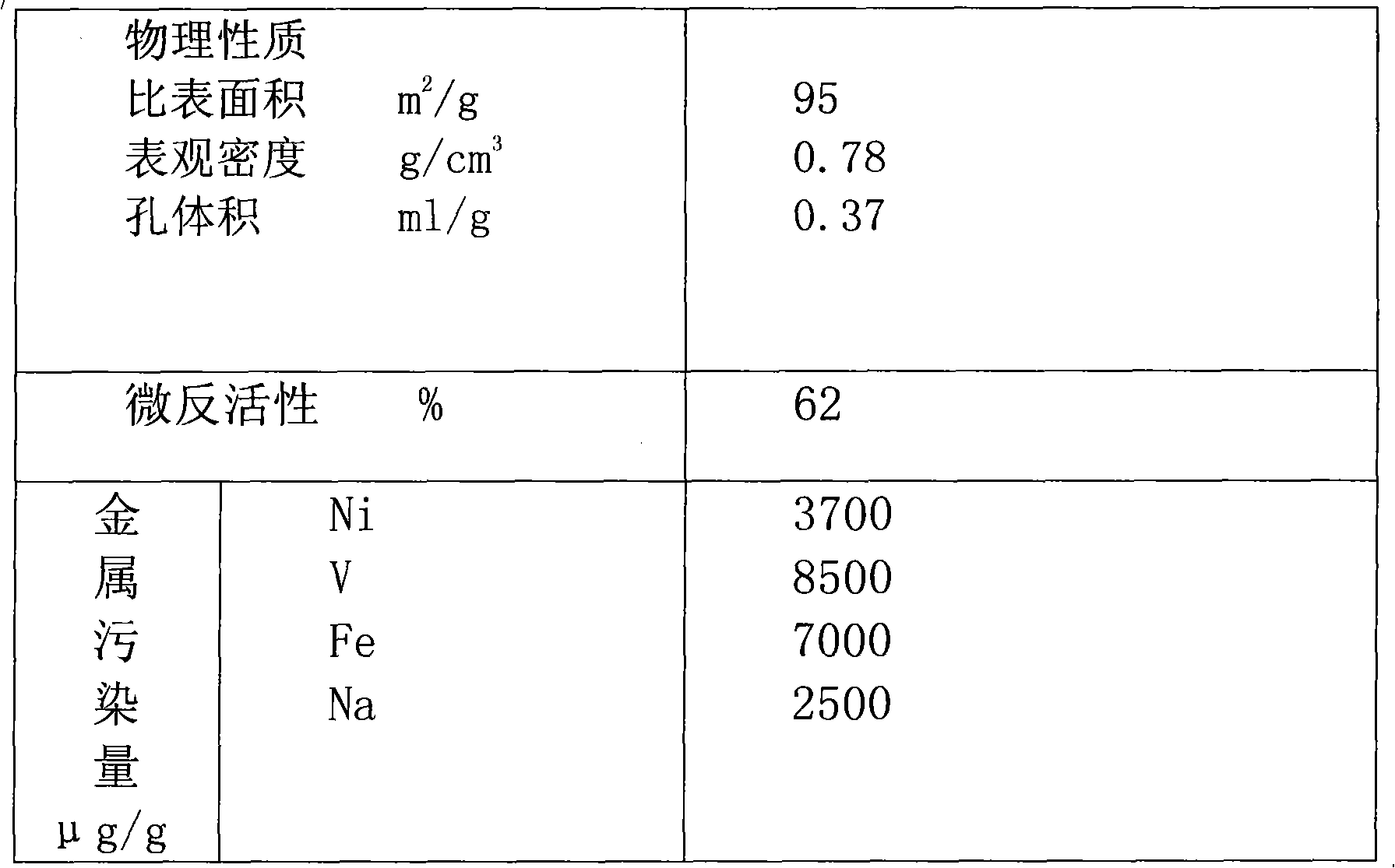

[0022] Properties of Table 2CC-20 Equilibrium Catalyst

[0023]

[0024] project

[0025] Table 4 Product distribution (%) and pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com