Ethylene cracking furnace coking restrainer and its use method

A technology of coking inhibitor and ethylene cracking furnace, which is applied in the direction of hydrocarbon cracking, hydrocarbon cracking, cracking, non-catalytic thermal cracking, etc., can solve the problem that the furnace tube life cannot be effectively improved, the yield of ethylene and the utilization rate of raw materials, and the coking inhibitor can not be uniform distribution, can not effectively reduce the production volume and other problems, to achieve a good effect of inhibiting coking, reducing the metal surface temperature and pressure difference of the furnace tube, preventing carburization and preventing the formation of coke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

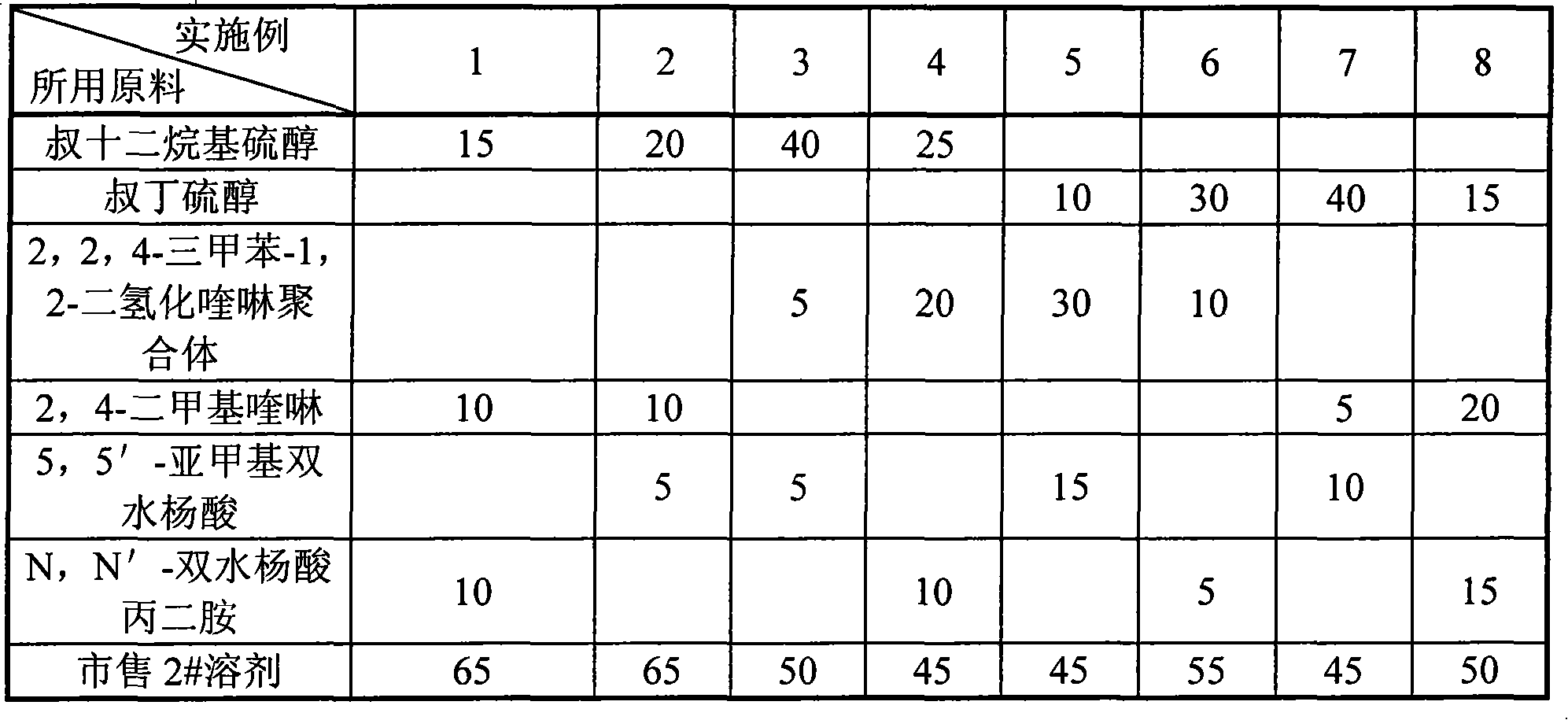

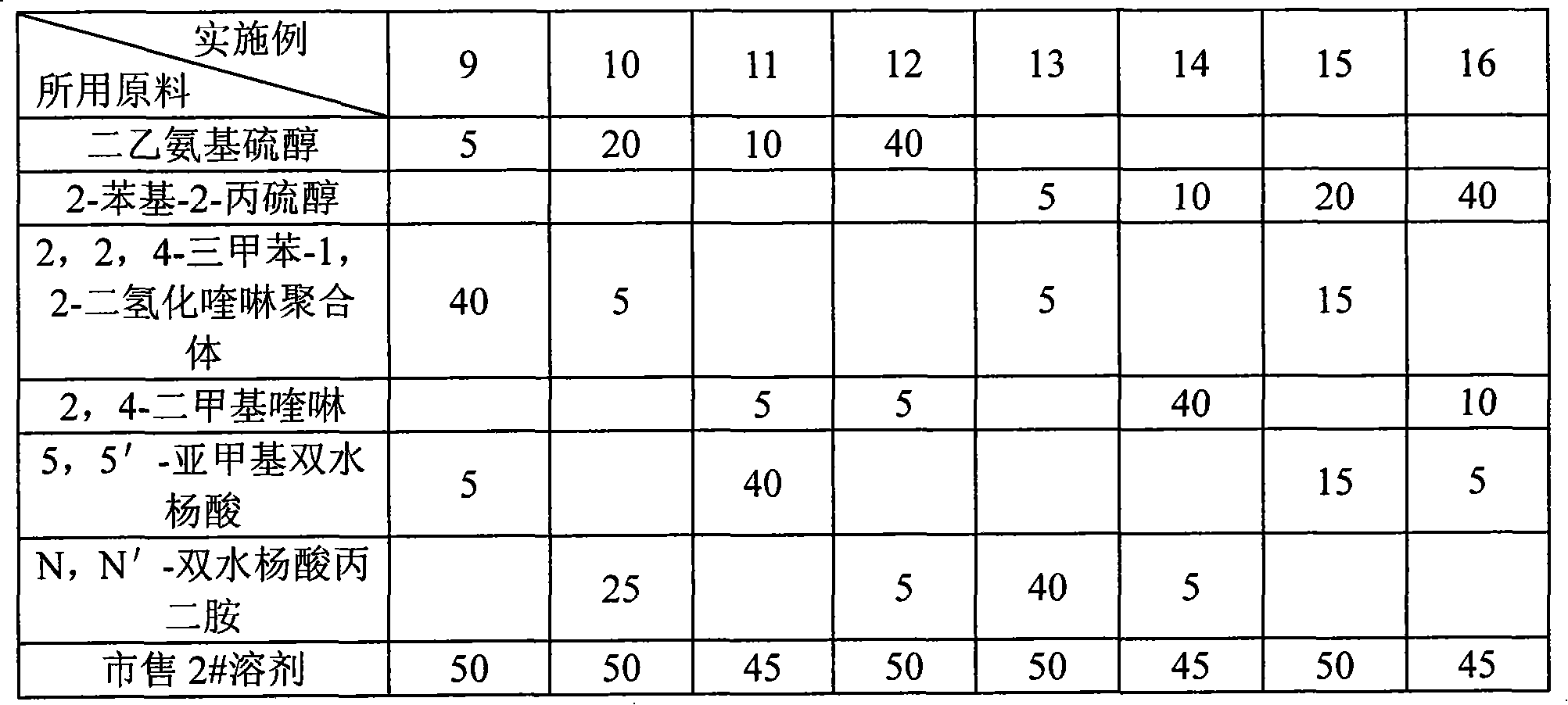

Examples

Embodiment 17

[0022] The coking inhibitor in Example 1 was applied to the simulated cracking furnace experiment. The experimental furnace type was STRIII, and the cracking temperature was set at 880°C. The raw material oil was naphtha, and the gasoline ratio was 0.6; The raw oil inlet of the furnace is continuously injected into the raw oil online, the residence time in the cracking furnace tube is 0.1s, and the mass concentration of the coking inhibitor after injection is 500ppm. The operation period of the equipment is 130 days, and the yield of the total triene is 52.84%.

Embodiment 18

[0024] The coking inhibitor in Example 2 was applied to the simulated cracking furnace experiment. The experimental furnace type was STRIII, and the cracking temperature was set at 880°C. The raw material oil was naphtha, and the gasoline ratio was 0.6, and the residence time in the cracking furnace tube was 0.1 The mass concentration of coking inhibitor after s injection is 450ppm. The operation period of the equipment is 126 days, and the yield of total triene is 52.67%.

Embodiment 19

[0026] The coking inhibitor in Example 3 was applied to the simulated cracking furnace experiment. The experimental furnace type was STRIII, and the cracking temperature was set at 880°C. The raw material oil was naphtha, and the gasoline ratio was 0.6. The raw oil inlet of the furnace is continuously injected into the raw oil online, and the residence time in the cracking furnace tube is 0.1s. After injection, the mass concentration of the coking inhibitor is 400ppm. The operation period of the equipment is 123 days, and the yield of total triene is 51.36%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com