Application of celery native ester stearic acid in glutamic acid fermentation

A fatty acid ester and glutamic acid technology, applied in the field of biochemistry, can solve problems such as no reports of glutamic acid fermentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0062] Strain: Corynebacterium glutamicum T-613, preserved by Guangzhou Institute of Microbiology.

[0063] The fermentation process consists of two steps of strain cultivation and fermentation:

[0064] (1) Strain culture: connect a ring of bacteria from the slope to the seed medium, fill 20mL of liquid in a 250mL shaker bottle, rotate at a speed of 96r / min, temperature 33°C, culture time 12-14h, 0D 650 Values greater than 0.5 culture termination.

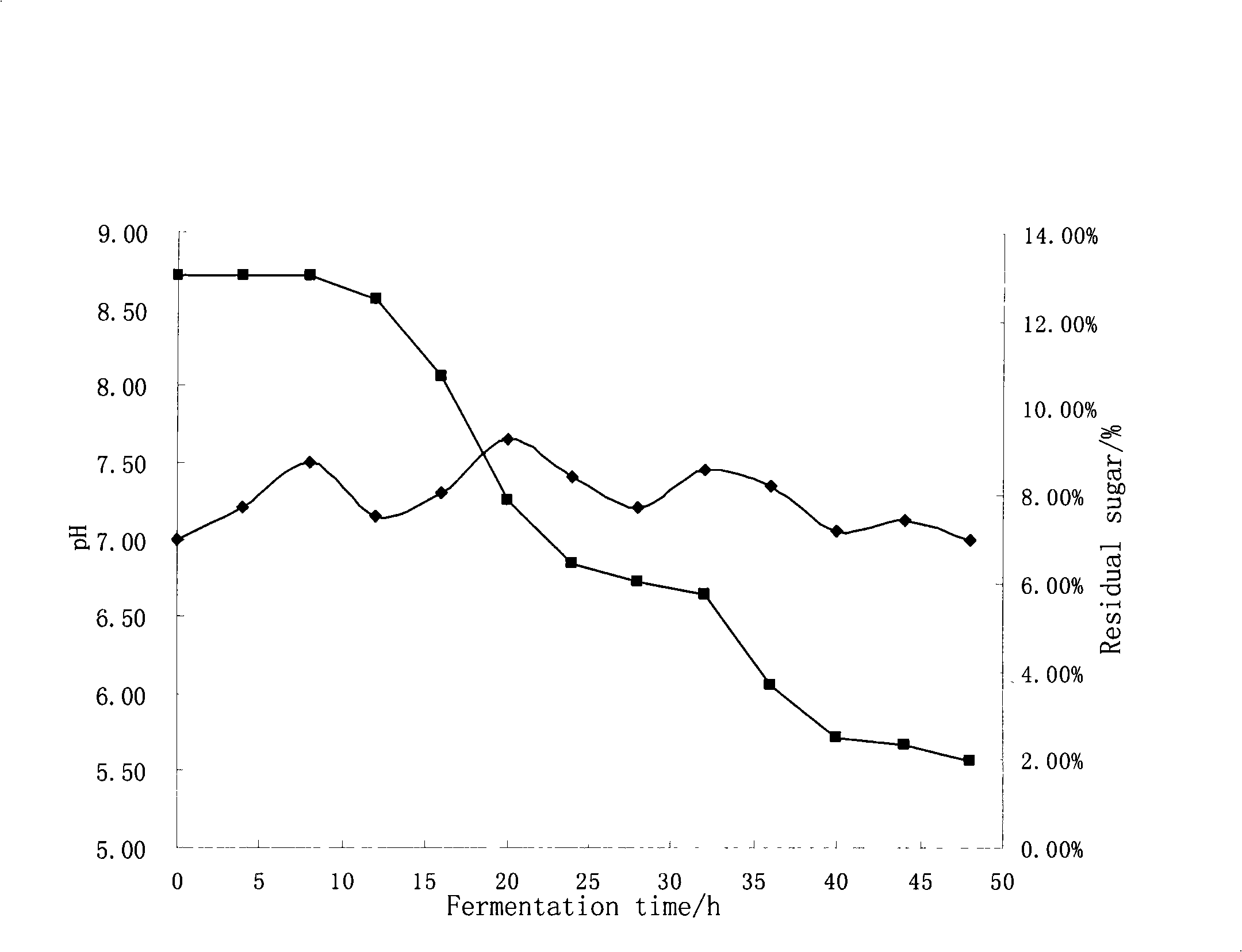

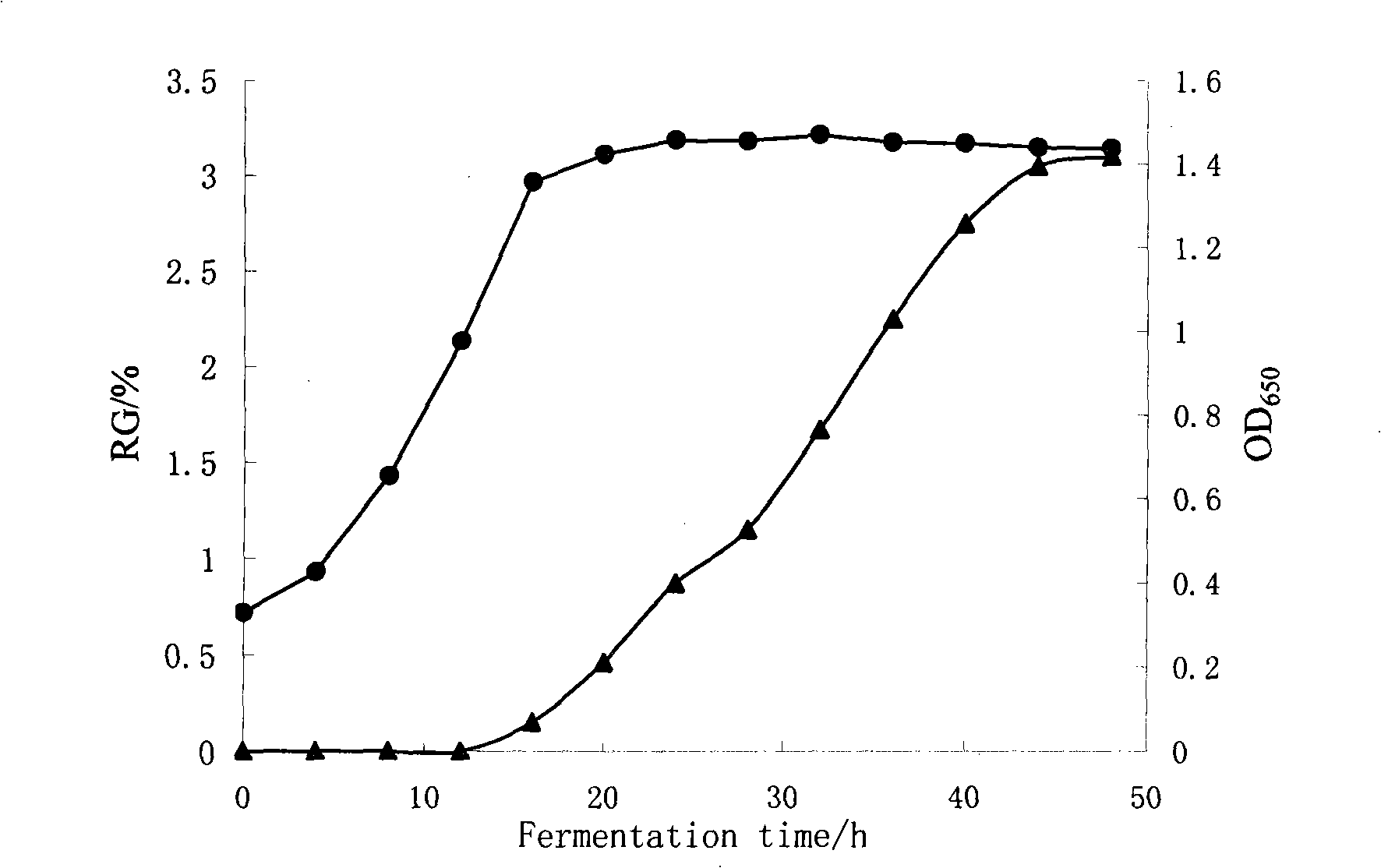

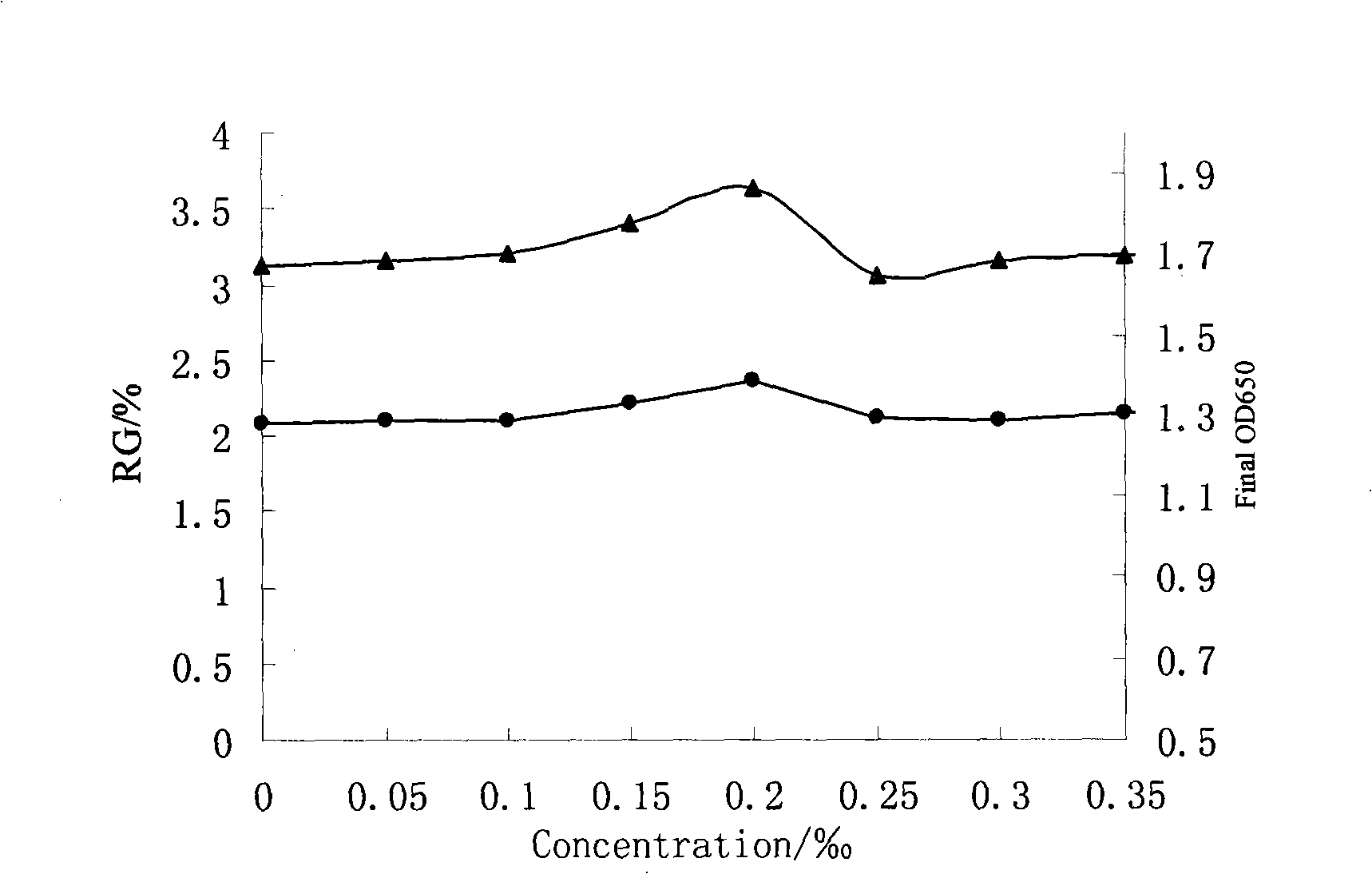

[0065] (2) Fermentation: Insert the seed culture solution into the fermentation medium according to 5% inoculation amount, 250mL liquid volume is 20mL, the shaker speed is 96r / min in the early stage of fermentation 0-16h, the temperature is 33.5°C, and the speed in the middle stage of fermentation is 115r / min in 16-40h min, temperature 36°C, 40-48h late stage of fermentation, shaker speed 105r / min, temperature 38°C, add 0.05‰ apigenin stearate at 12h, culture time 48h;

[0066] in,

[0067] Described seed culture medium (%) c...

example 2

[0071] Strain: Corynebacterium glutamicum T-613, preserved by Guangzhou Institute of Microbiology.

[0072] The fermentation process consists of two steps of strain cultivation and fermentation:

[0073] (1) Strain cultivation: connect a ring of bacteria from the slope to the seed medium, fill 20mL of liquid in a 250mL shaker bottle, rotate at a speed of 96r / min, temperature 33°C, culture time 12-14h, OD 650 Values greater than 0.5 culture termination.

[0074] (2) Fermentation: Insert the seed culture solution into the fermentation medium according to the inoculum size of 5%, 250mL liquid volume is 20mL, the shaker speed is 96r / min in the early stage of fermentation 0-16h, the temperature is 33.5°C, and the speed in the middle stage of fermentation is 115r / min in 16-40h min, temperature 36°C, 40-48h late stage of fermentation, shaker speed 105r / min, temperature 38°C, add 0.2‰ apigenin stearate at 16h, culture time 48h;

[0075] in,

[0076] Described seed medium (%) cons...

example 3

[0080] Strain: Corynebacterium glutamicum T-613, preserved by Guangzhou Institute of Microbiology.

[0081] The fermentation process consists of two steps of strain cultivation and fermentation:

[0082] (1) Strain cultivation: connect a ring of bacteria from the slope to the seed medium, fill 20mL of liquid in a 250mL shaker bottle, rotate at a speed of 96r / min, temperature 33°C, culture time 12-14h, OD 650 Values greater than 0.5 culture termination.

[0083] (2) Fermentation: Insert the seed culture solution into the fermentation medium according to the inoculum size of 5%, 250mL liquid volume is 20mL, the shaker speed is 96r / min in the early stage of fermentation 0-16h, the temperature is 33.5°C, and the speed in the middle stage of fermentation is 115r / min in 16-40h Min, temperature 36°C, 40-48h late stage of fermentation, shaker speed 105r / min, temperature 38°C, add 0.1‰ apigenin stearate at 14h, culture time 48h;

[0084] in,

[0085] Described seed medium (%) consis...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap