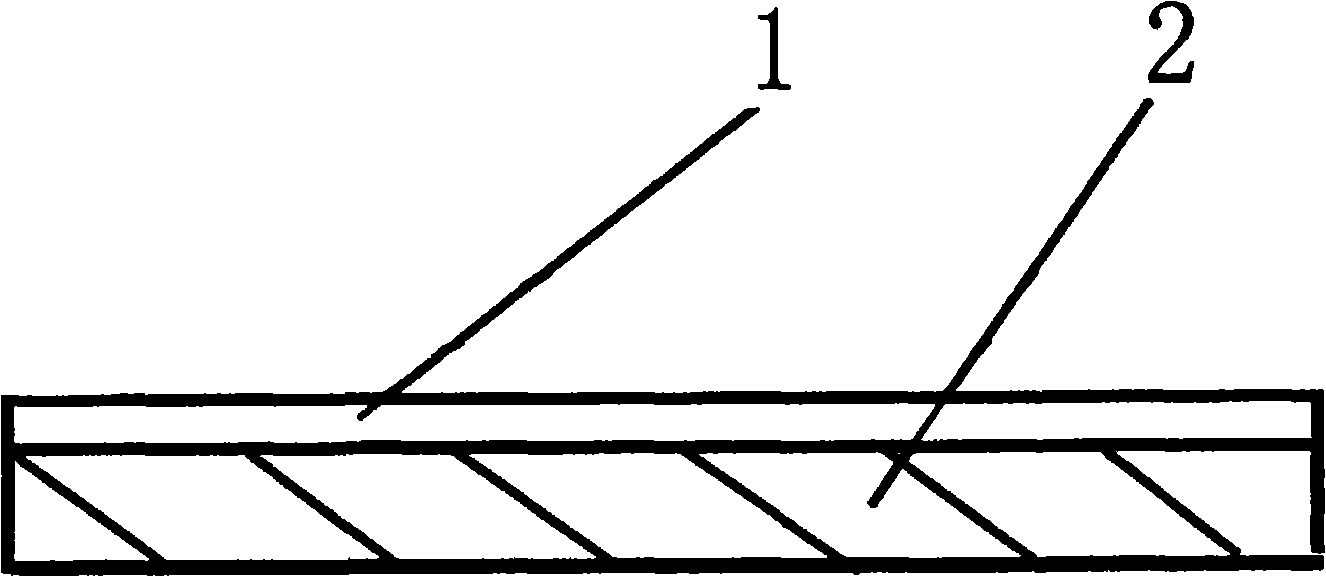

Surface recombination technique of veneer and plaster tablets

A technology of surface composite and gypsum board, which is applied in the field of preparation of composite building decoration materials, can solve the problems of fire hazards, low fire protection level and strength, and long wood growth cycle, so as to improve the fire resistance level, reduce decoration costs, and improve fire protection required effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The composite process of veneer and gypsum board surface includes the following steps:

[0025] 1. Preparation of veneer

[0026] Use round wood or square wood to cut it out with a woodworking planer. The thickness is 0.1mm, and the length and width are determined according to the products produced; the moisture content of the veneer is controlled below 12%; the veneer used is hemlock, cloud One of the veneers of fir, walnut, cherry, toon, and beech.

[0027] 2. Surface treatment of gypsum board and veneer

[0028] Treat the surface of the gypsum board by grinding it with emery cloth to increase its roughness until it feels slightly rough to the touch, and do not over-grind; gently blow the rough surface of the gypsum board with hot air; also clean the adhesive surface of the veneer;

[0029] 3. Glue

[0030] Apply glue evenly on the rough surface of the gypsum board and the glued surface of the wood veneer, the glue amount is 100g / m 2 , the adhesive used is LK-140 ...

Embodiment 2

[0036] The composite process of veneer and gypsum board surface includes the following steps:

[0037] 1. Preparation of veneer

[0038] Use round wood or square wood to slice it out with a woodworking planer. The thickness is between 2mm, and the length and width are determined according to the products produced; the moisture content of the veneer is controlled below 12%; the veneer used is hemlock, One of spruce, walnut, cherry, toon, beech veneer.

[0039] 2. Surface treatment of gypsum board and veneer

[0040] Treat the surface of the gypsum board by grinding it with emery cloth to increase its roughness until it feels a little rough to the touch, and do not over-grind; dry the rough surface of the gypsum board with hot air; also clean the adhesive surface of the veneer ;

[0041] 3. Glue

[0042] Apply glue evenly on the rough surface of the gypsum board and the glued surface of the wood veneer, the glue amount is 180g / m 2 , the adhesive used is LK-140 water-based e...

Embodiment 3

[0048] The composite process of veneer and gypsum board surface includes the following steps:

[0049] 1. Preparation of veneer

[0050] Use round wood or square wood to cut it out with a woodworking planer. The thickness is between 1mm, and the length and width are determined according to the products produced; the moisture content of the veneer is controlled below 12%; the veneer used is hemlock, One of spruce, walnut, cherry, toon, beech veneer.

[0051] 2. Surface treatment of gypsum board and veneer

[0052] Treat the surface of the gypsum board by grinding it with emery cloth to increase its roughness until it feels a little rough to the touch, and do not over-grind; dry the rough surface of the gypsum board with hot air; also clean the adhesive surface of the veneer ;

[0053] 3. Glue

[0054] Apply glue evenly on the rough surface of the gypsum board and the glued surface of the wood veneer, the glue amount is 150g / m 2 , the adhesive used is LK-140 water-based env...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com