Tank furnace drawing process and apparatus

A pool kiln wire drawing and process technology, applied in the direction of manufacturing tools, glass manufacturing equipment, feeding troughs, etc., can solve problems that cannot be adjusted in time, affect product quality, and are not accurate enough, so as to expand production capacity and reasonable Utilization and selection, the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

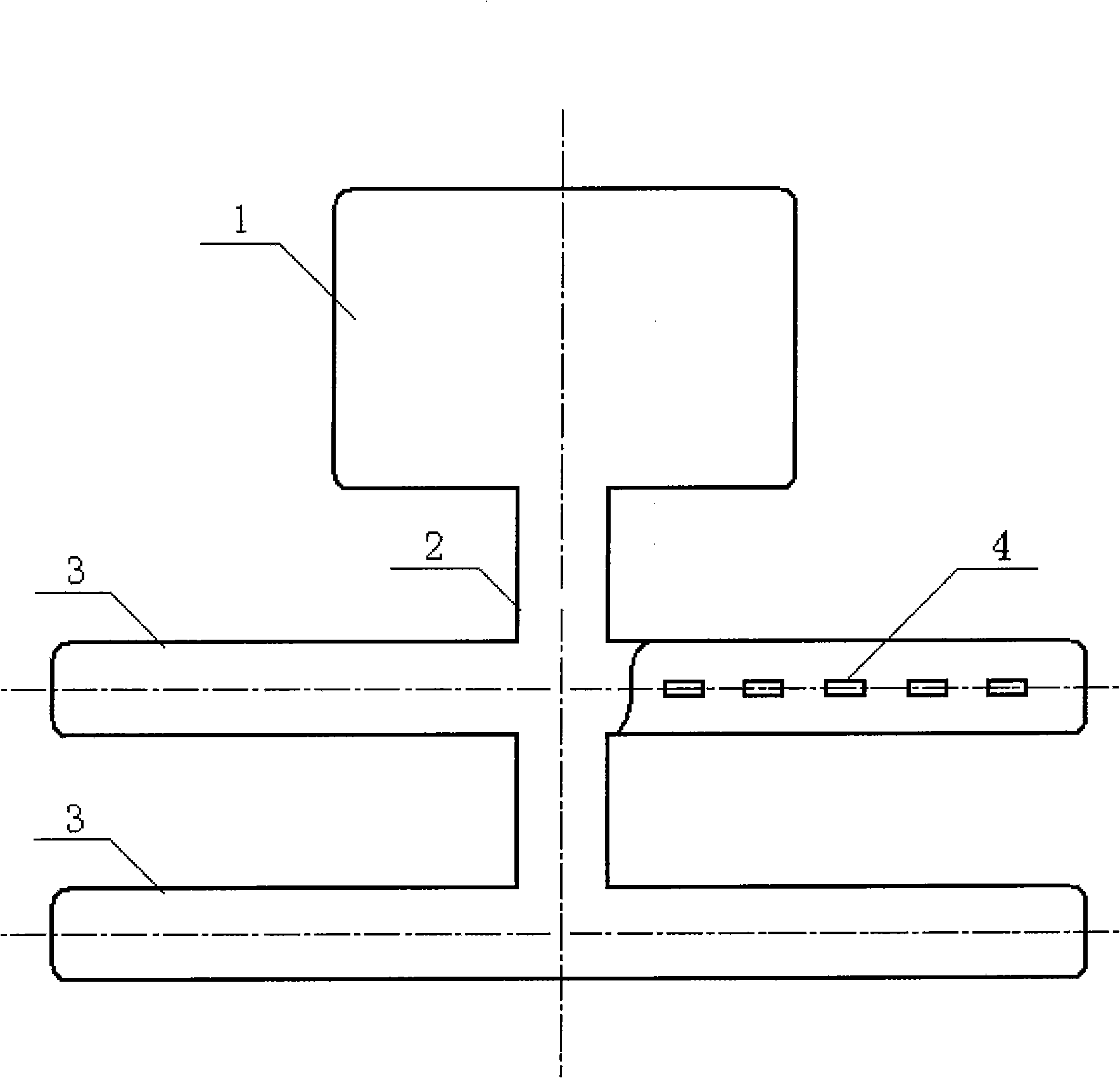

[0014] Embodiment 1: as figure 1 As shown, the feeding device injects raw materials into the melting tank 1 of the kiln, and the melting tank of the tank kiln is connected to the longitudinal main passage 2, and the main passage is respectively connected to the horizontal drawing passages 3 on both sides, with one row as a group and two sets of drawing passages An H-shaped structure is formed. After the raw materials are heated in the tank kiln, they are melted to form a glass liquid with uniform and flowable components, and then gently flow into the H-shaped wire drawing channel from the main channel. If necessary, the same method can also be used to move backward Several rows of wire-drawing passages are extended, and a bushing 5 is provided at the lower part of the wire-drawing passages.

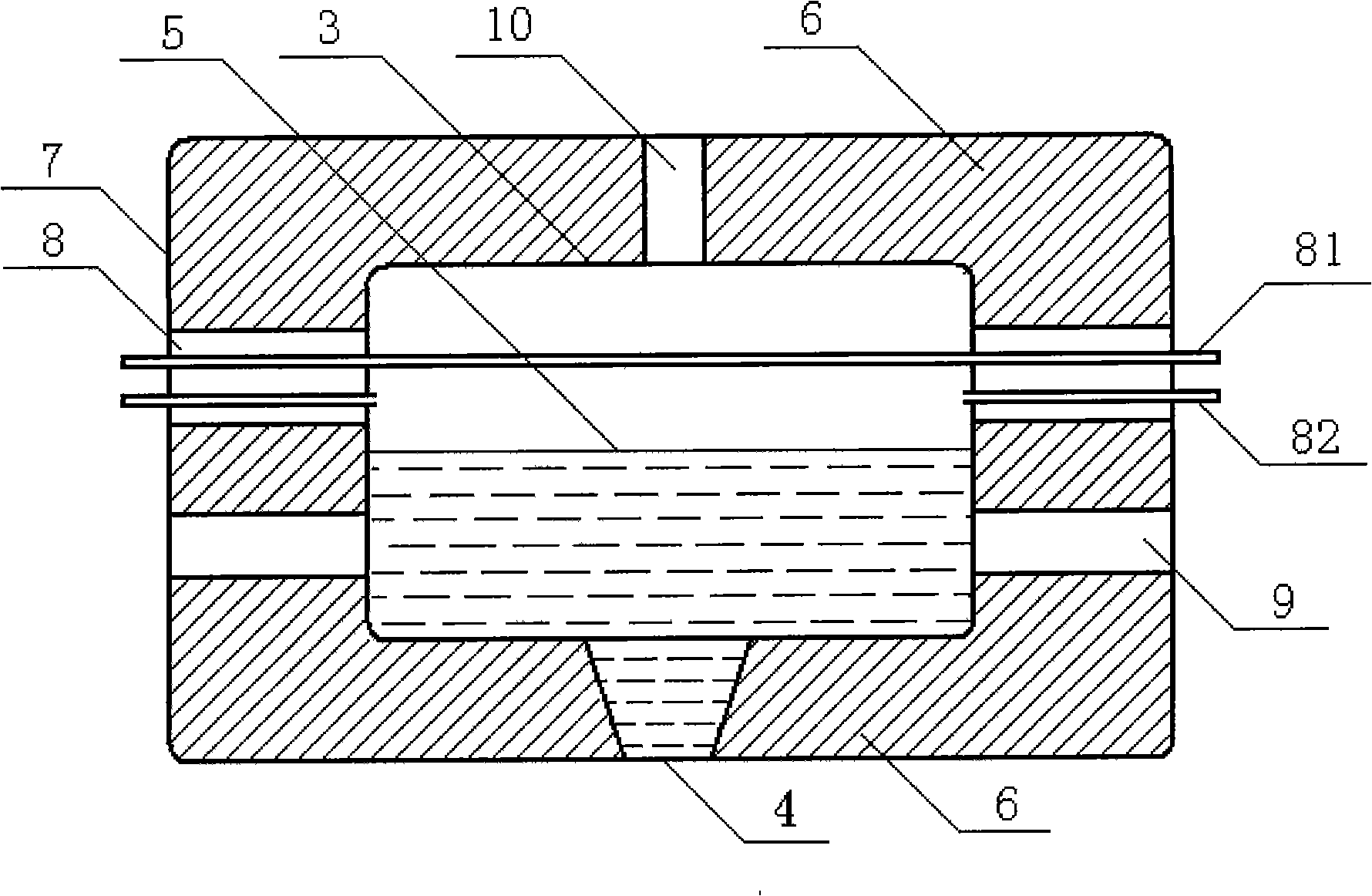

[0015] The structure of the drawing channel is as figure 2 As shown, the wire-drawing passage 3 is a continuous device, and several bushings 4 are provided at the lower part. The main p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com