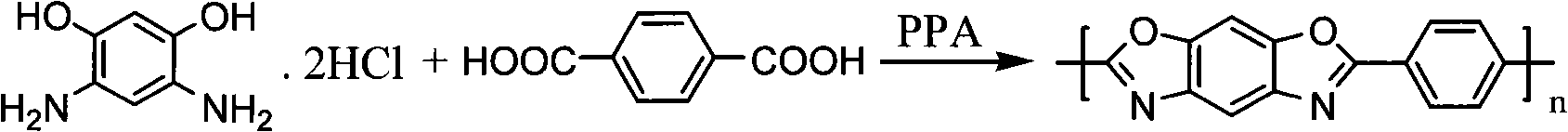

Preparation of polybenzoxazole

A technology of polybenzoxazole and polyphosphoric acid, which is applied in the field of preparation of polybenzoxazole, can solve the problems of increased side reactions, long polymerization time, and high requirements, so as to shorten the polymerization reaction time, simplify the reaction process, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Add 5.2 kilograms of 4,6-diaminoresorcinol / terephthalic acid compound salt into the polyphosphoric acid solvent containing phosphorus pentoxide (wherein: 16.5 kilograms of polyphosphoric acid, 6.7 kilograms of phosphorus pentoxide) , under the protection of an inert gas, mix and dissolve for 3 hours at 60°C to form a polyphosphoric acid mixed solution of 4,6-diaminoresorcinol / terephthalic acid compound salt; the mixed solution is directly fed into the twin-screw , the set temperature of the screw is 120-190 ° C, the residence time is 50 minutes, and the yellow-green polybenzoxazole spinning slurry with stirring fluorescence is obtained, and the spinning slurry is washed with water to remove polyphosphoric acid, and obtain Polybenzoxazole. A small amount of this polymer was dissolved in methanesulfonic acid to prepare a solution with a concentration of 0.02-0.05g / dl, and its intrinsic viscosity at 30°C was determined to be 30.2dL / g.

Embodiment 2

[0017] Add 6.8 kilograms of 4,6-diaminoresorcinol / terephthalic acid compound salt into the polyphosphoric acid solvent containing phosphorus pentoxide (wherein: 21.4 kilograms of polyphosphoric acid, 8.9 kilograms of phosphorus pentoxide) , under the protection of an inert gas, mix and dissolve for 2 hours at 80°C to form a polyphosphoric acid mixed solution of 4,6-diaminoresorcinol / terephthalic acid compound salt; the mixed solution is directly fed into the twin-screw , the set temperature of the screw is 150-200 ° C, the residence time is 30 minutes, and the yellow-green polybenzoxazole spinning slurry with stirring fluorescence is obtained, and the spinning slurry is washed with water to remove polyphosphoric acid, and obtain Polybenzoxazole. A small amount of this polymer was dissolved in methanesulfonic acid to prepare a solution with a concentration of 0.02-0.05g / dl, and its intrinsic viscosity at 30°C was determined to be 32.5dL / g.

Embodiment 3

[0019] Add 4.4 kilograms of 4,6-diaminoresorcinol / terephthalic acid compound salt into the polyphosphoric acid solvent containing phosphorus pentoxide (wherein: 13.7 kilograms of polyphosphoric acid, 6 kilograms of phosphorus pentoxide) , under the protection of an inert gas, mix and dissolve for 4 hours at 80°C to form a polyphosphoric acid mixed solution of 4,6-diaminoresorcinol / terephthalic acid compound salt; the mixed solution is directly fed into the twin-screw , the set temperature of the screw is 150-190 ° C, the residence time is 50 minutes, and a yellow-green polybenzoxazole spinning slurry with stirring fluorescence is obtained. The spinning slurry is washed with water to remove polyphosphoric acid, and obtain Polybenzoxazole. A small amount of this polymer was dissolved in methanesulfonic acid to prepare a solution with a concentration of 0.02-0.05g / dl, and its intrinsic viscosity at 30°C was determined to be 34.5dL / g.

[0020] The PBO slurry obtained by the polym...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com