Highly effective flame-retardant environment-protective thermoplastic plastic and making process thereof

A thermoplastic and environmentally friendly technology, applied in the direction of conductors, electrical components, circuits, etc., can solve problems such as aggravated aging, reduced insulation performance, and fire spread

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

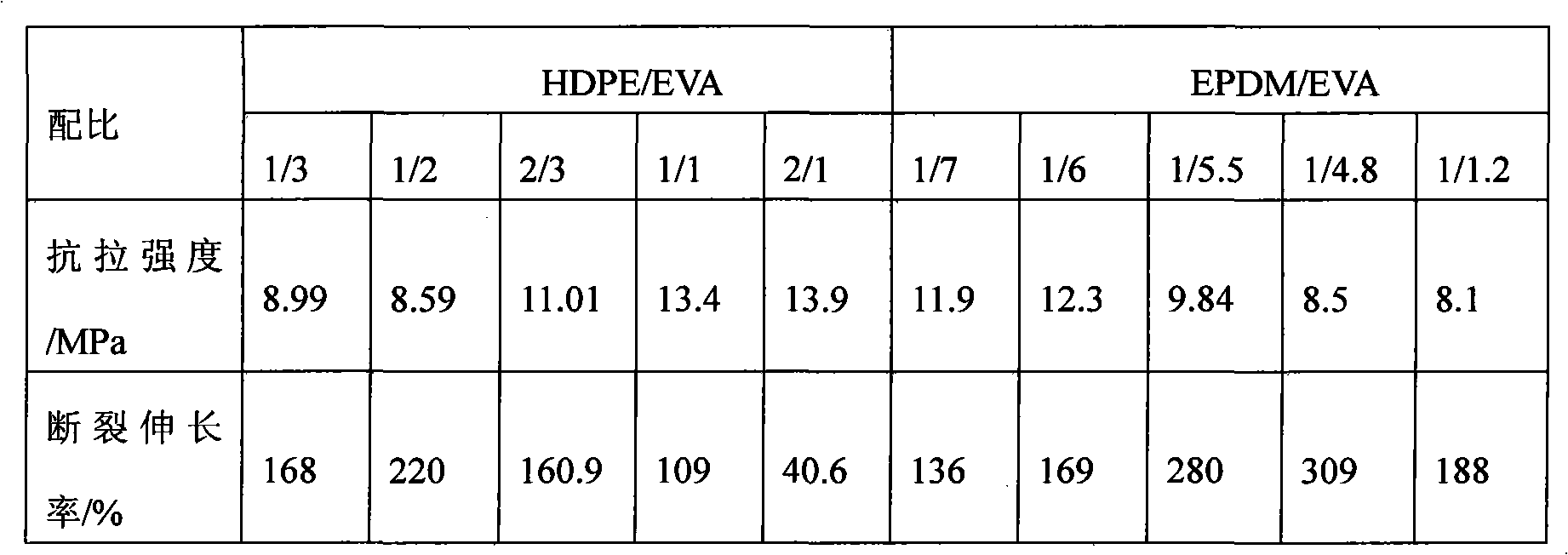

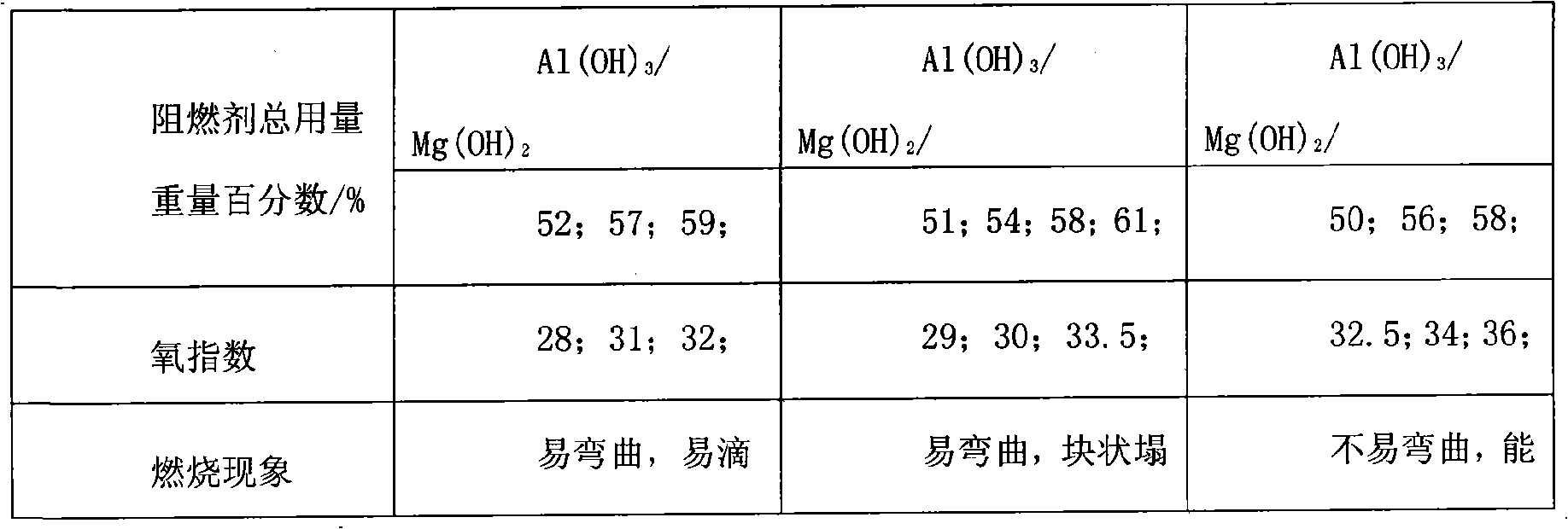

Method used

Image

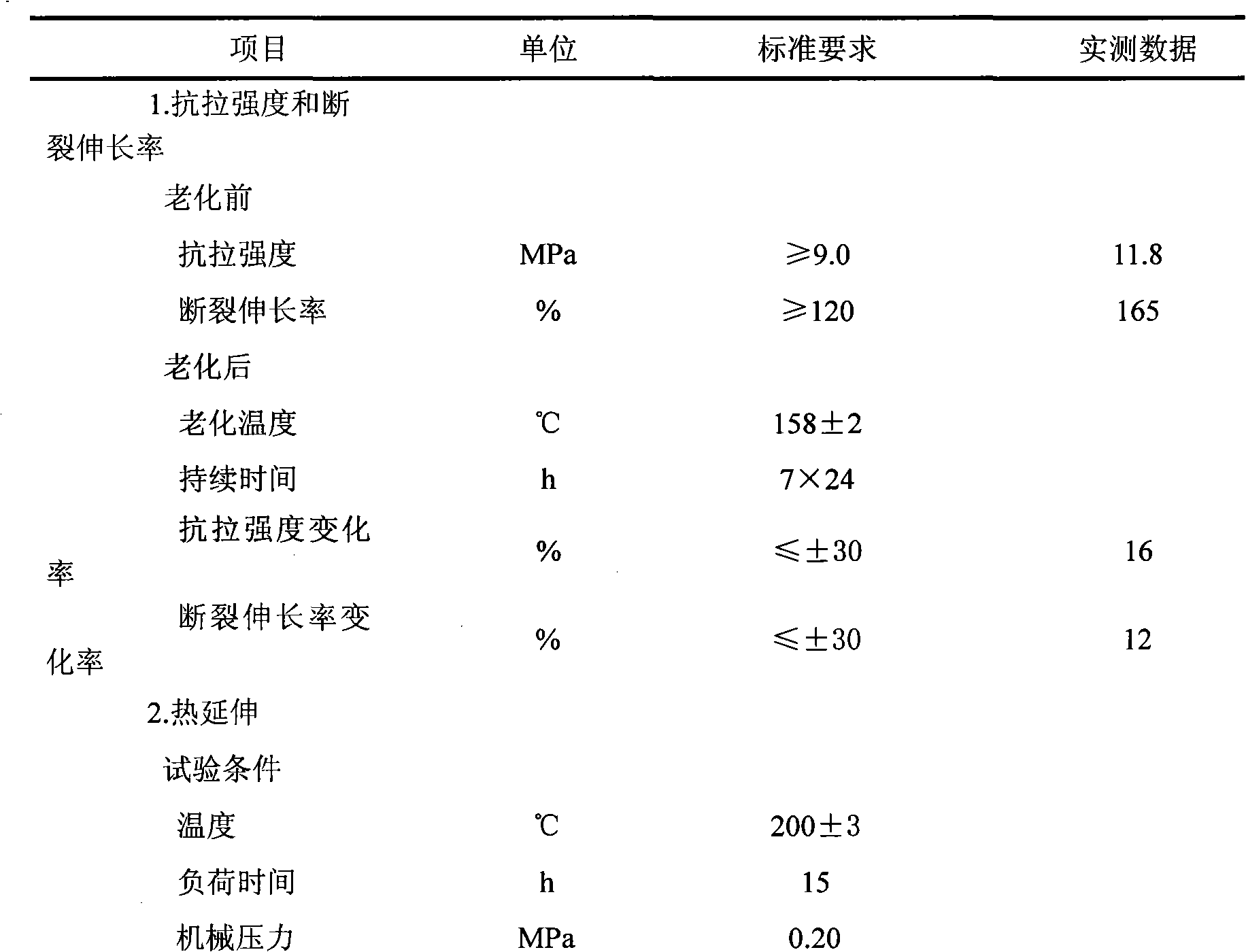

Examples

Embodiment 1

[0049] The formula composition and its weight points are as follows:

[0050] Ingredients Quantity (parts by weight)

[0051] Ethylene-vinyl acetate copolymer 65

[0052] HDPE 20

[0053] Al(OH) 3 100

[0054] Mg(OH) 3 40

[0055] Flame Retardant Synergistic Organic Flame Retardant 7

[0056] Maleic anhydride compatibilizer 25

[0057] Pentaerythyl ester antioxidant 0.5

[0058] Lubricant 0.8

[0059] Nano charcoal masterbatch 6

Embodiment 2

[0061] The formula composition and its weight points are as follows:

[0062] Ingredients Quantity (parts by weight)

[0063] Ethylene-vinyl acetate copolymer 55

[0064] HDPE 20

[0065] Al(OH) 3 80

[0066] Mg(OH) 3 50

[0067] Flame Retardant Synergistic Organic Flame Retardant 10

[0068] Maleic anhydride compatibilizer 28

[0069] Pentaerythyl ester antioxidant 0.8

[0070] lubricant 1

[0071] Nano carbon masterbatch 3

Embodiment 3

[0073] The formula composition and its weight points are as follows:

[0074] Ingredients Quantity (parts by weight)

[0075] Ethylene-vinyl acetate copolymer 60

[0076] HDPE 22

[0077] Al(OH) 3 90

[0078] Mg(OH) 3 55

[0079] Flame Retardant Synergistic Organic Flame Retardant 8

[0080] Maleic anhydride compatibilizer 30

[0081] Pentaerythyl ester antioxidant 1

[0082] Lubricant 0.9

[0083] Nano charcoal masterbatch 10

[0084] The specific manufacturing process of above-mentioned embodiment 1, embodiment 2, embodiment 3 is as follows: 1)

[0085] Weigh raw materials by weight;

[0086] 2) Al(OH) in ethylene-vinyl acetate copolymer, high-density polyethylene, compatibilizer, antioxidant, lubricant and formula 3 , Mg(OH) 3 Pour 50% of the formula into the internal mixer to fully mix the plastic additives with the powdered product. When the material temperature reaches 80°C±5°C and the material in the machine will be agglomera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com