Flow field plate for measuring fuel battery local current density

A technology for local current and density measurement, applied in the direction of current density measurement, measurement of electricity, measurement device, etc., can solve the problems of electrode change, measurement error, processing difficulty, etc., to achieve the effect of convenient processing, high measurement accuracy and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

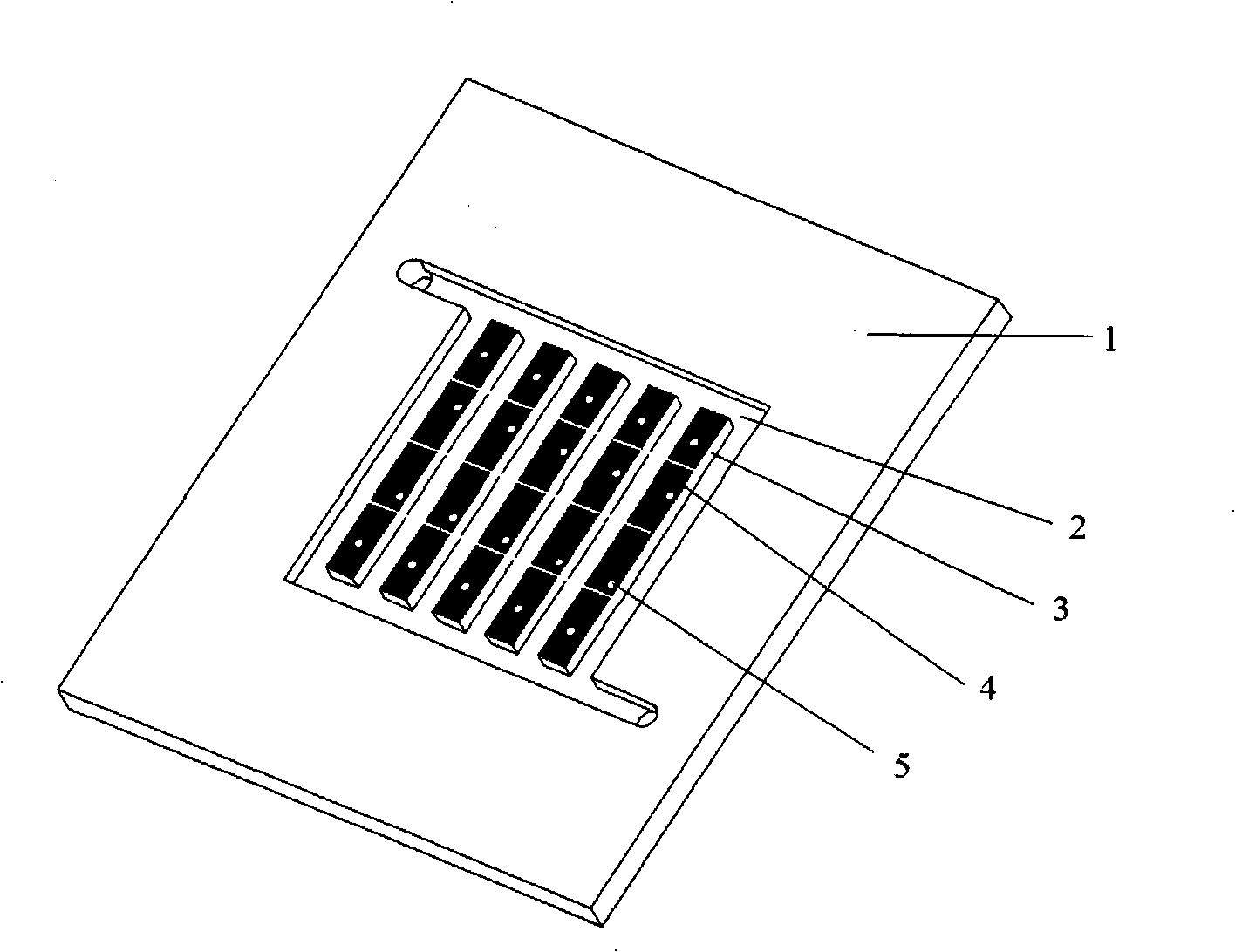

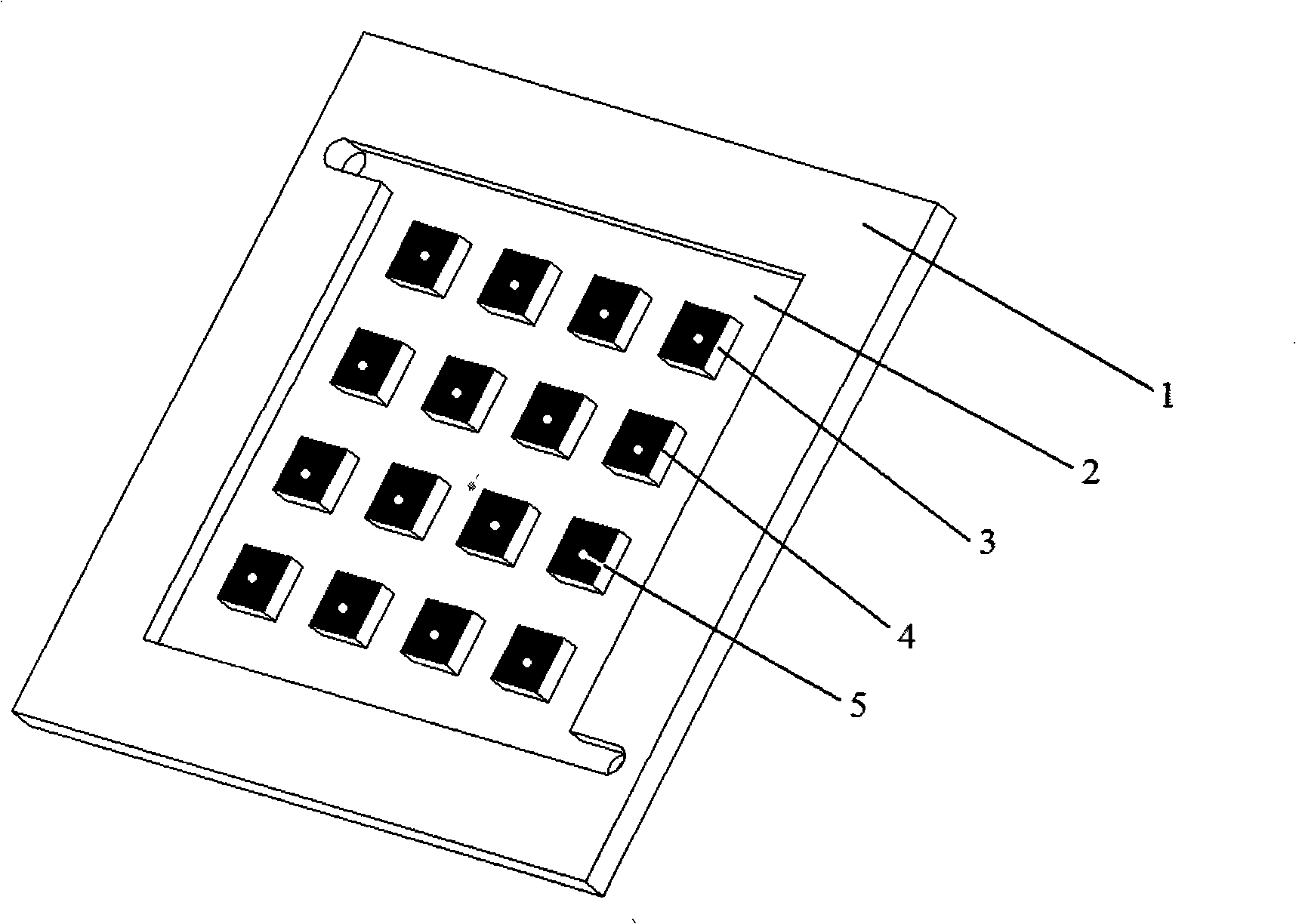

[0019] refer to figure 1 , using the existing PCB technology, the gas flow channel 2 is directly processed on the printed circuit board (PCB board 1), and the ribs 3 between the flow channels are covered with an independent metal plating area 4. When measuring the local current density of the fuel cell , the reaction gas flows in the gas flow channel 2, and the metal coating area 4 on the rib 3 is tightly pressed against the membrane electrode, which is responsible for leading out the current of the membrane electrode area corresponding to the metal coating area. The metal plating area 4 adopts copper plating or silver plating. An electrical connection point 5 is provided on the metal plating area 4, and the electrical connection point 5 is a gold plating point.

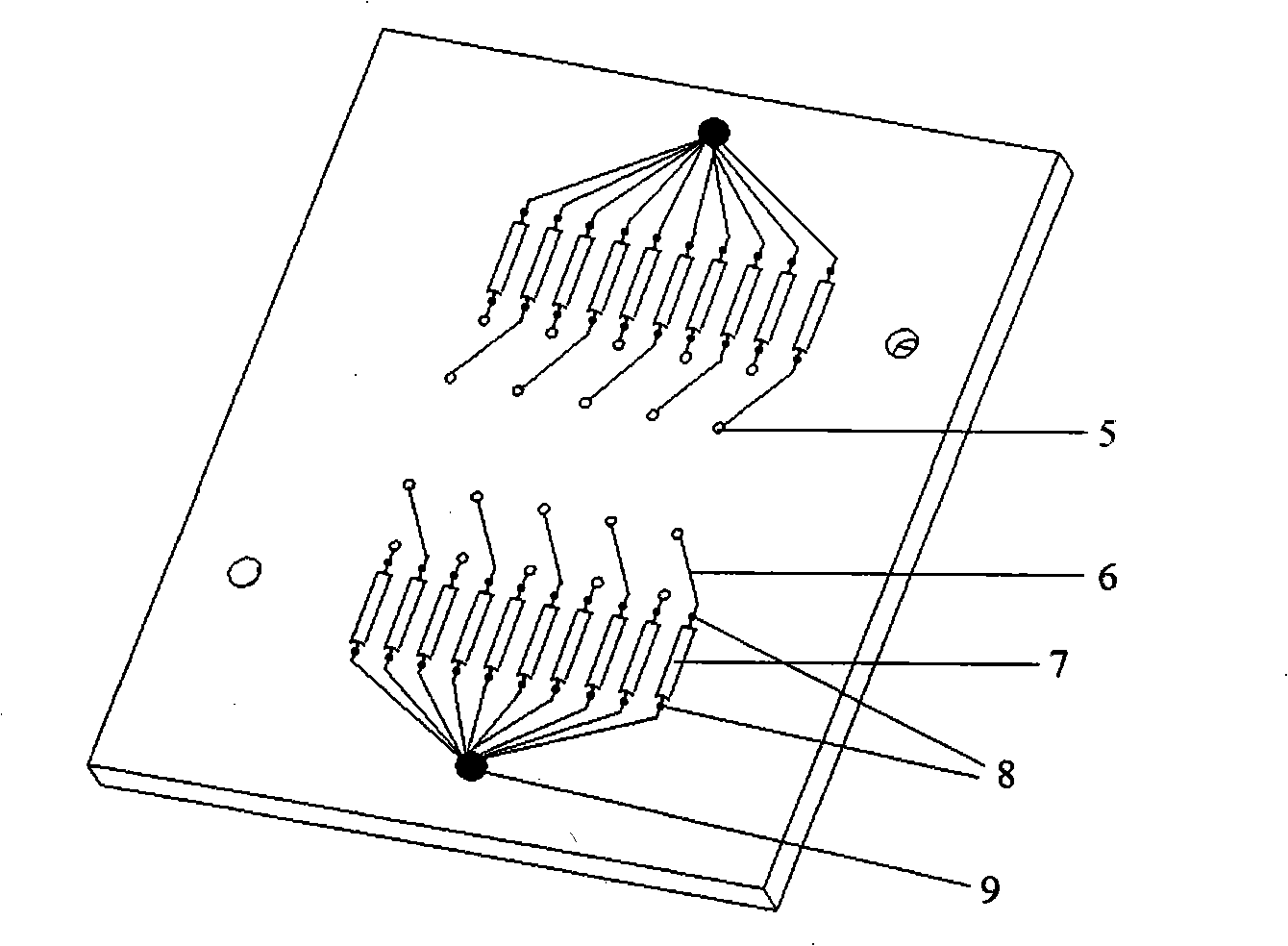

[0020] refer to figure 2 , the current derived from the metal plating area 4 leads to the wire 6 on the back of the PCB through the electrical connection point 5 and passes through the small resistor 7, and finall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com