Method for selecting gear during the process of making steep slope of vehicle

A gear selection, vehicle technology, applied to components with teeth, belts/chains/gears, mechanical equipment, etc., can solve the problems of vehicles losing propulsion, starting, etc., and achieve the effect of low fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

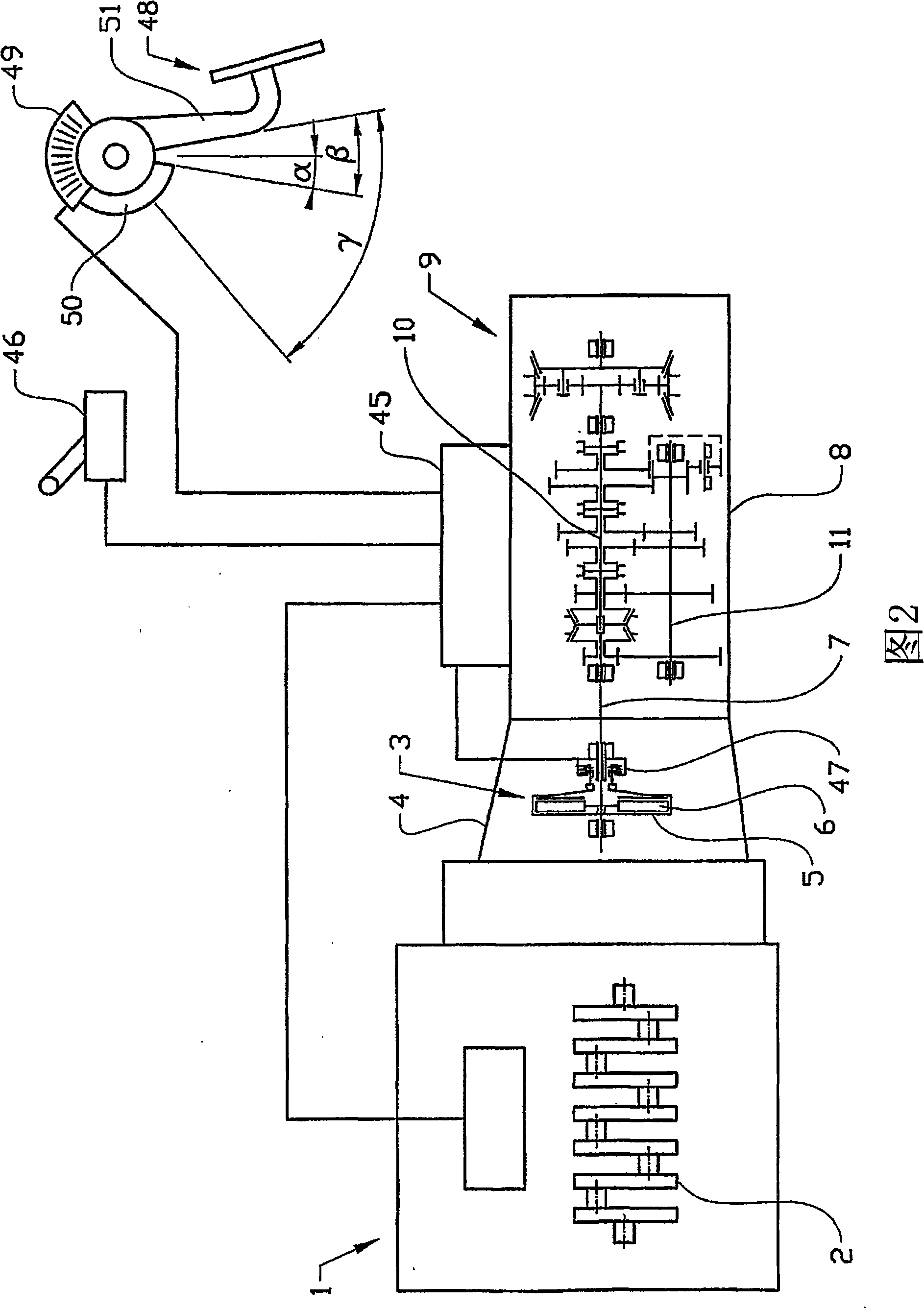

[0031] In one embodiment, the wheel is fitted with an internal combustion engine 1 , such as a diesel engine, with a crankshaft 2 coupled to a single-plate dry plate clutch 3 enclosed in a clutch housing 4 . The crankshaft 2 is non-rotatably connected to an input shaft 7 which is rotatably mounted within a housing 8 of a gearbox 9 . A main shaft 10 and an intermediate shaft 11 are also rotatably mounted within the gearbox housing 8 . The gear is rotatably mounted on the input shaft and can be locked on the shaft by means of a synchronizing device provided with a coupling sleeve, the synchronizing device is non-rotatably but axially displaceable mounted on a hub, the shaft is non-rotatable ground to the output shaft. By means of the described coupling sleeve, the gear wheel mounted rotatably on the main shaft can be locked relative to the input shaft 7 . By means of said coupling sleeves in the neutral position, said gears are decoupled from their respective shafts. The gear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com