A large area organic diode device and a method of manufacturing it

A diode and organic technology, applied in the field of organic diode devices, can solve the problems of complex manufacturing, winding of electric leads, etc., and achieve the effect of improving electrical contact and long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

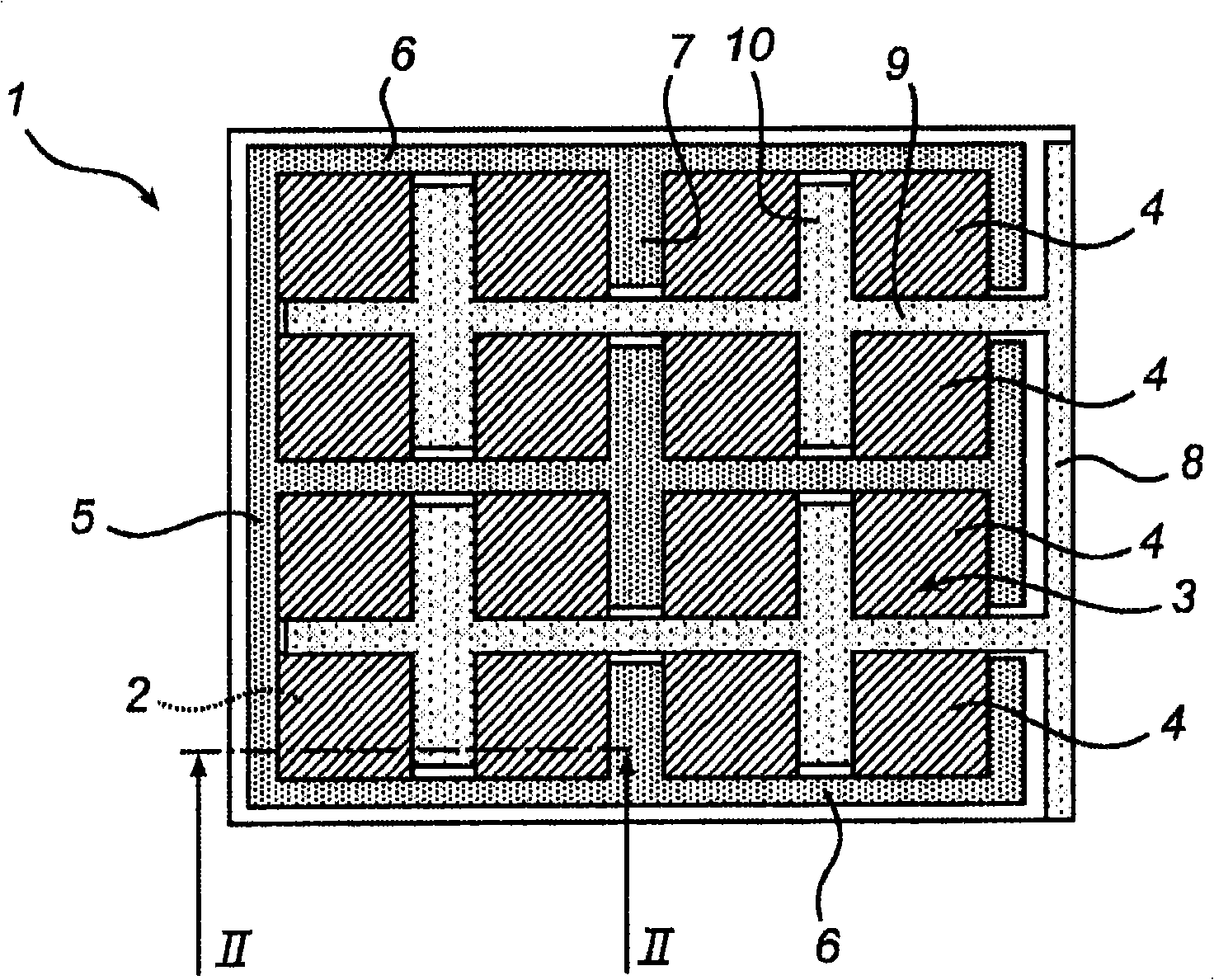

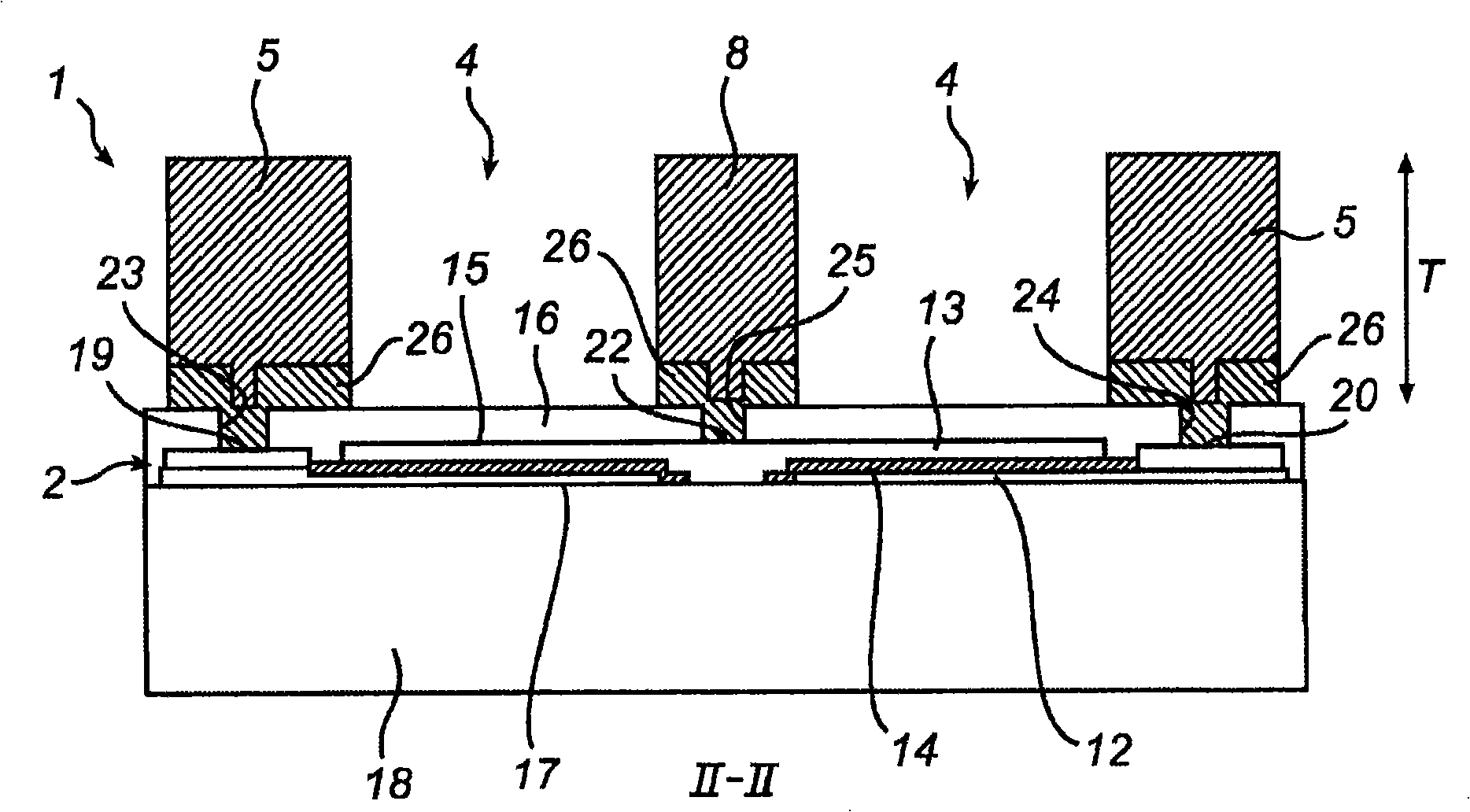

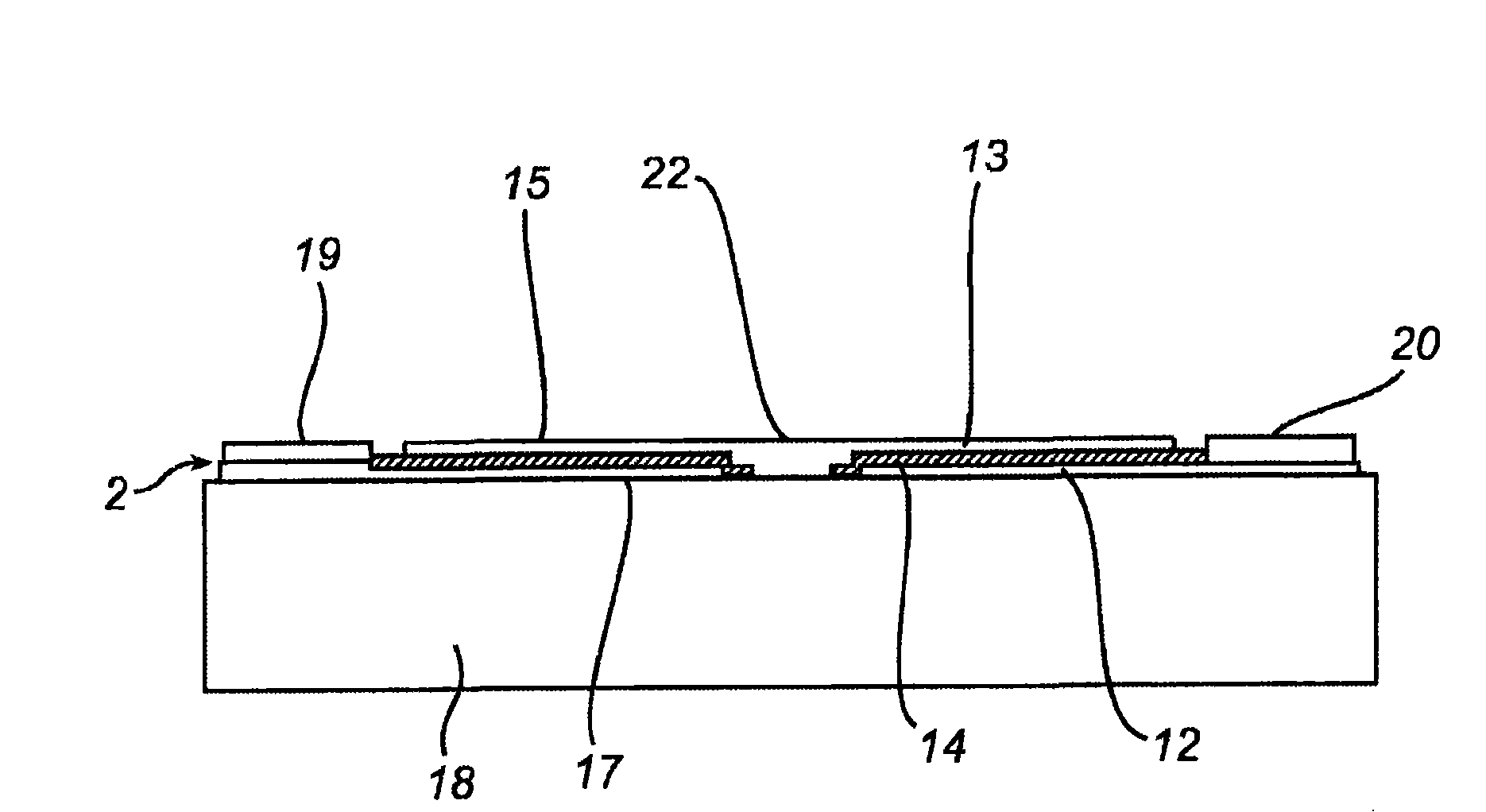

[0038] figure 1 An organic diode device in the form of a light emitting device 1 is shown. The light emitting device 1 comprises a light emitting structure 2, which is in figure 2 is shown in more detail. The light emitting device 1 has a large surface 3 which is divided into small pieces 4 . The first metal conductor 5 formed by electroplating as will be described below forms a first grid on the surface 3 . Such as figure 1 As can be seen in , the first metal conductor 5 includes a trunk 6 and branches 7 so as to make the first metal conductor 5 contact all the small pieces 4 . A second metal conductor 8 formed by electroplating as will be described below forms a second grid on the surface 3 . Such as figure 1 As can be seen in , the second metal conductor 8 includes a trunk 9 and branches 10 so as to make the second metal conductor 8 contact all the small pieces 4 . The first metal conductor 5 and the second metal conductor 8 are isolated from each other. Each of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com