Preparation of Bi2Te3 thermoelectric compound nanopowder

A nano-powder and compound technology is applied in the field of preparation of Bi2Te3 thermoelectric compound nano-powder, which can solve problems such as being difficult to obtain, and achieve the effects of simple production equipment, uniform particle distribution, and simple and easy-to-control process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

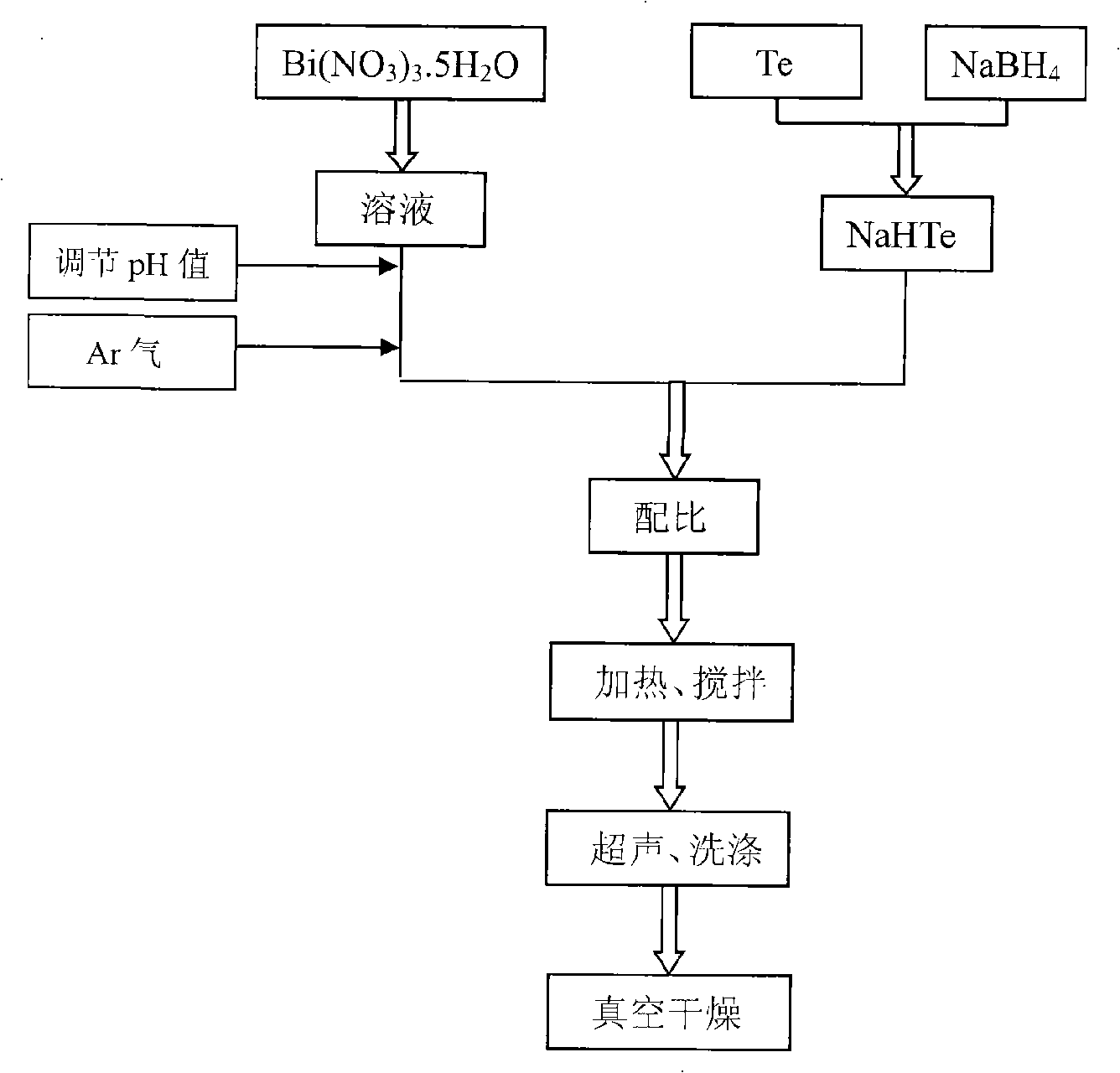

[0021] like figure 1 As shown, a Bi 2 Te 3 A method for preparing a thermoelectric compound nanopowder, which comprises the steps of:

[0022] 1). Combine 4mmolTe and 8mmolNaBH 4 Place in a glass bottle with a rubber stopper to mix, and add 8ml of deionized water; then place the glass bottle in an ice-water bath and stir for 1 hour. During the reaction, the system communicates with the atmosphere through a small pinhole, and stirs to obtain NaHTe solution with clear color is A solution;

[0023] 2). Prepare Bi(NO at a concentration of 0.5mol / L 3 ) 3 ·5H 2 O aqueous solution 50ml, adjust pH value to be 12 (adjust pH value with alkali, as NaOH), be B solution;

[0024] 3). After degassing solution B for 3 minutes under an Ar gas atmosphere, add 6ml of A solution; heat to 80°C under an Ar gas atmosphere, and stir for 4 hours; the reaction principle is as follows:

[0025] 2Na + +4BH 4 - +2Te+7H 2 O=2HTe - +Na 2 B 4 o 7 ↓+14H 2 ↑

[0026] 3HTe - +2Bi 3+ +3OH -...

Embodiment 2

[0031] A Bi 2 Te 3 A method for preparing a thermoelectric compound nanopowder, which comprises the steps of:

[0032] 1). Te: NaBH 4 After selecting at a molar ratio of 1:2.0, mix in a glass bottle with a rubber stopper, and add deionized water, the ratio of deionized water to Te is 4ml:1g; then place the glass bottle in an ice-water bath to stir the reaction 0.5 hours, during the reaction, the system communicated with the atmosphere through a small pinhole, and stirred to obtain a colorless and transparent NaHTe solution, which was A solution;

[0033] 2). Prepare Bi(NO at a concentration of 0.05mol / L 3 ) 3 ·5H 2 O aqueous solution, adjust pH value to be 9 (adjust pH value with alkali, as NaOH), be B solution;

[0034] 3). After degassing the B solution for 3 minutes under the Ar gas atmosphere, then add the A solution according to the molar ratio of Bi ions in the B solution to Te ions in the A solution = 2.1:3; heat to 70°C under the Ar gas atmosphere , stirring and...

Embodiment 3

[0037] A Bi 2 Te 3 A method for preparing a thermoelectric compound nanopowder, which comprises the steps of:

[0038] 1). Te: NaBH 4After selection at a molar ratio of 1:2.1, mix in a glass bottle with a rubber stopper, and add deionized water, the ratio of deionized water to Te is 32ml:1g; then place the glass bottle in an ice-water bath to stir the reaction For 3 hours, the system communicated with the atmosphere through a small pinhole during the reaction, and stirred to obtain a colorless and transparent NaHTe solution, which was A solution;

[0039] 2). Prepare Bi(NO at a concentration of 0.5mol / L 3 ) 3 ·5H 2 O aqueous solution, adjust the pH value to 12 (adjust the pH value with alkali, such as NaOH), be the B solution;

[0040] 3). After degassing the B solution for 10 minutes under an Ar gas atmosphere, then add the A solution according to the molar ratio of Bi ions in the B solution to Te ions in the A solution = 2.3:3; heat to 90°C under an Ar gas atmosphere ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com