Automobile speed variator of arc teeth cylindrical gear pair transmission

A technology of automobile transmission and cylindrical gear, applied in the direction of gear transmission, transmission box, transmission, etc., can solve the problems of complex transmission shaft support mechanism, low strength of cylindrical gear, shortened service life, etc., and achieves low noise and large overlap coefficient. , simple and compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

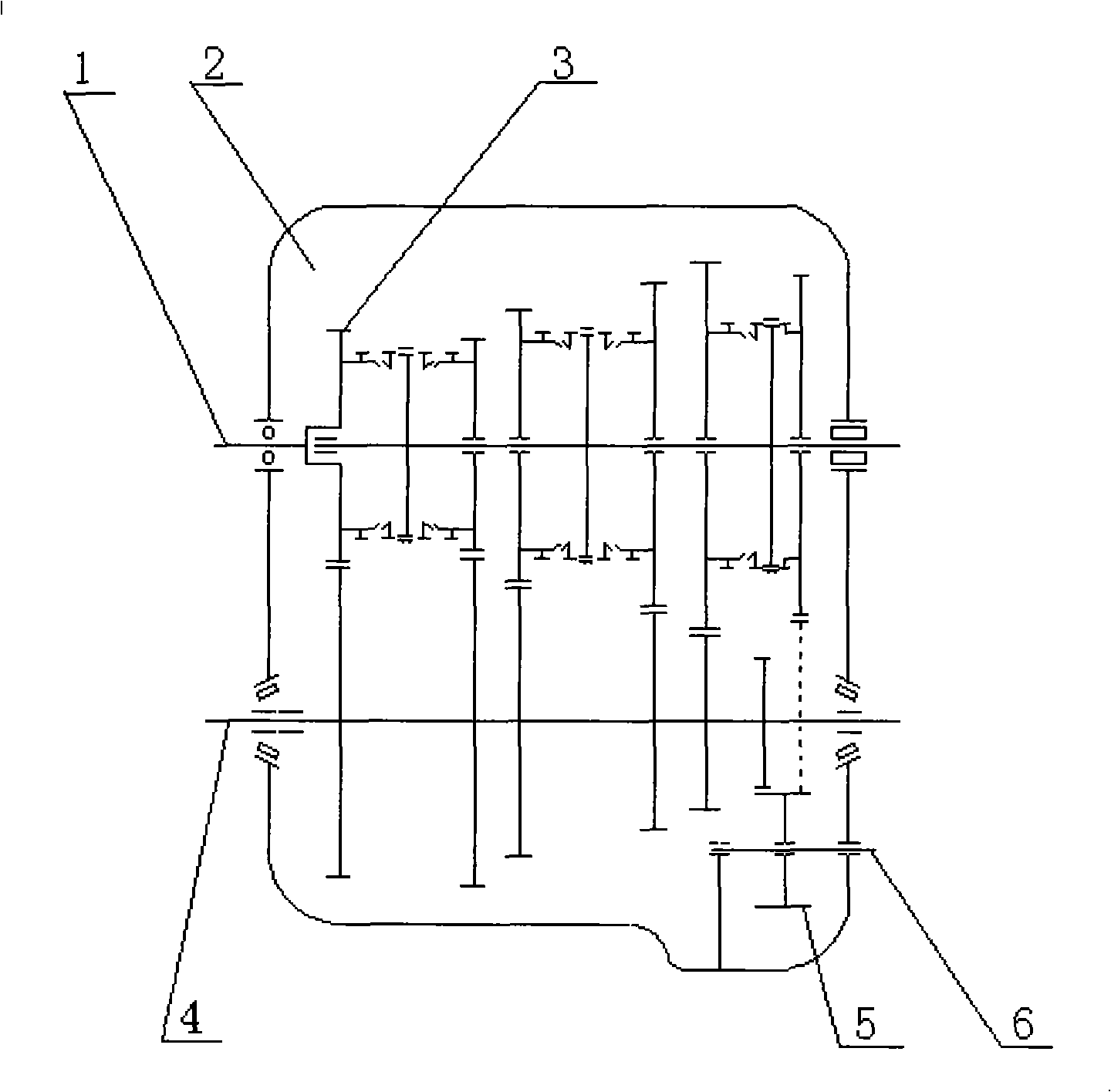

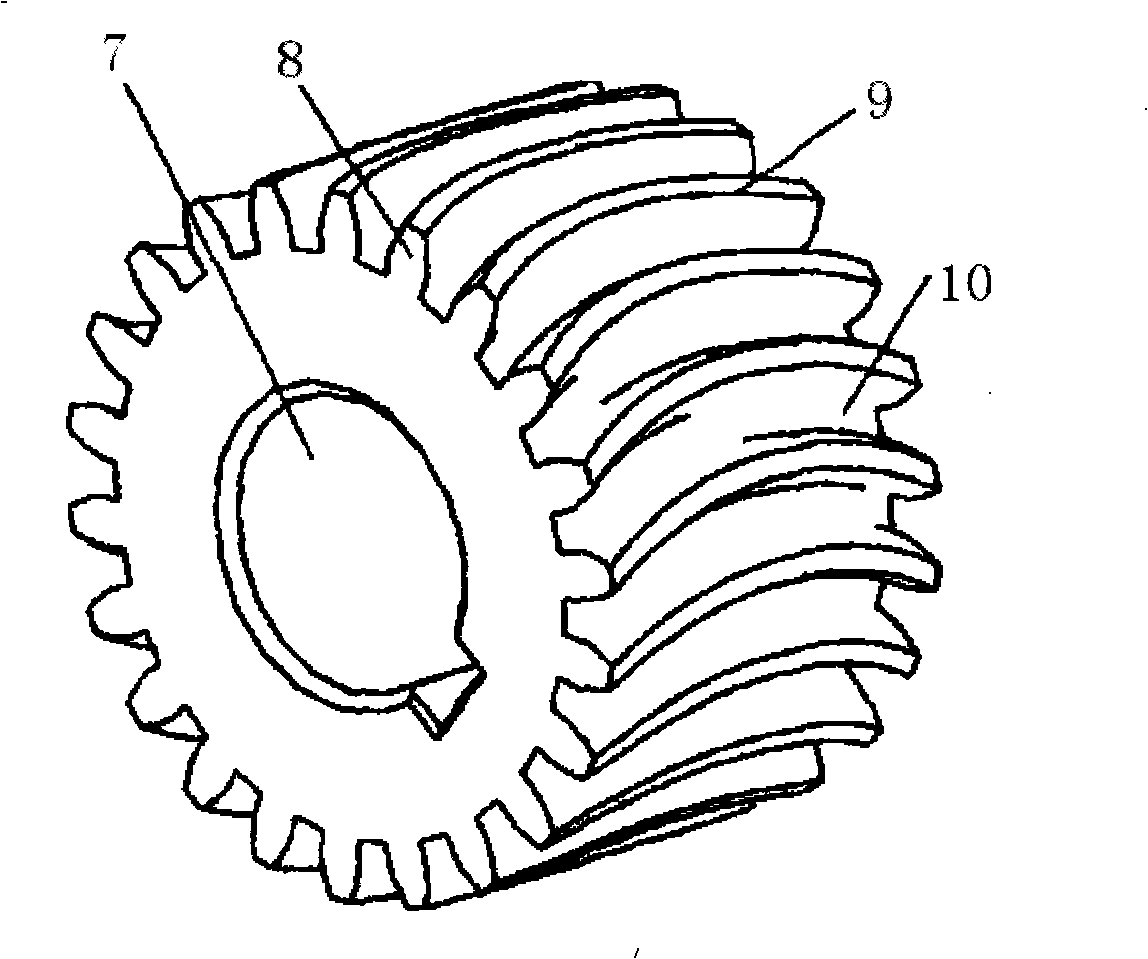

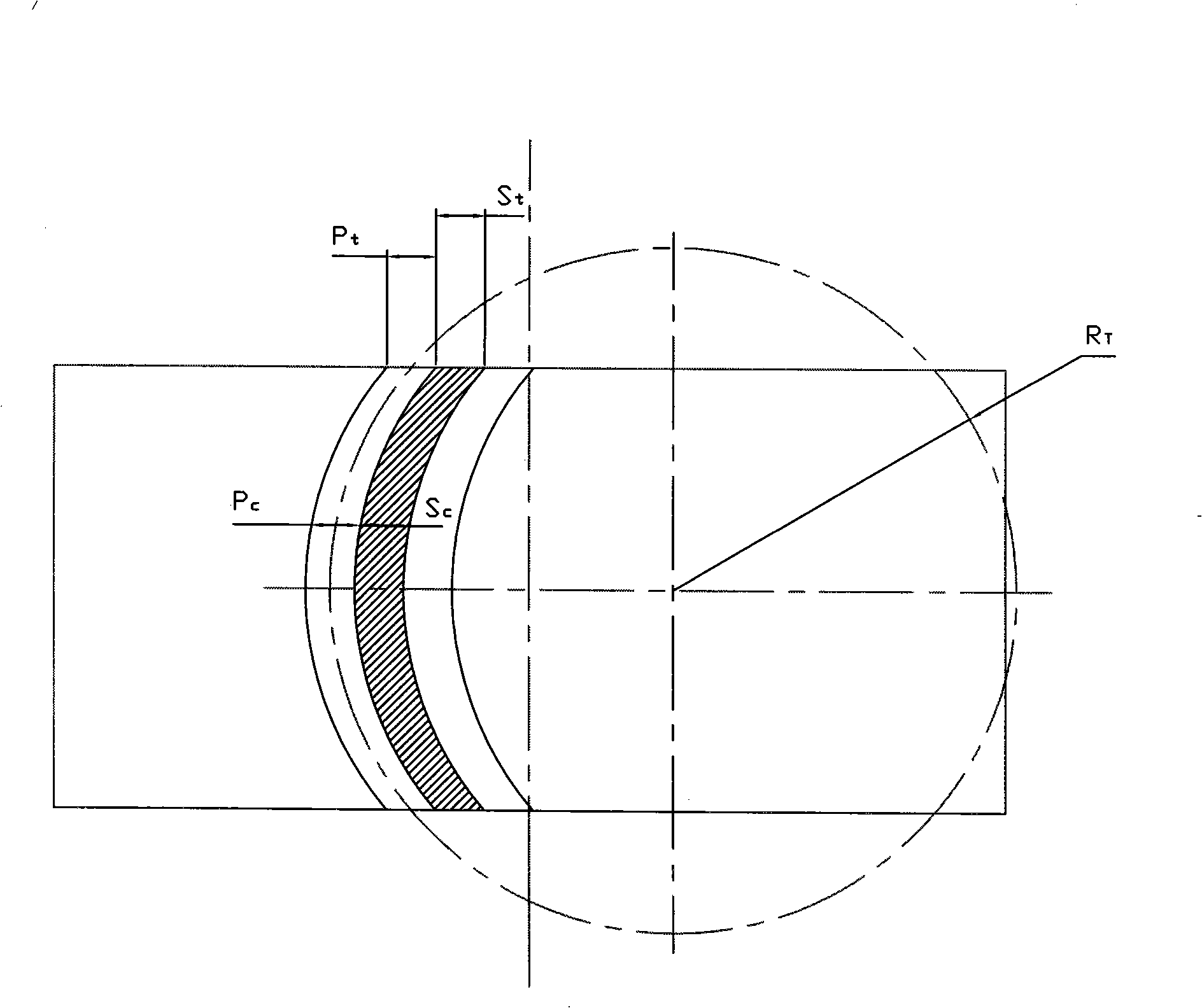

[0011] like figure 1 , 2 As shown, the car transmission with arc-toothed cylindrical gear pair transmission adopts arc-toothed cylindrical gear as the transmission gear. There is a shaft hole 7 on the gear, the tooth profile is an involute, the tooth line 9 is an arc line, and the arc of the tooth line The radius is greater than half of the gear thickness (the length between the two arc tooth end faces 8), and the arc radius of the tooth line is less than twice the gear thickness. The groove widths of the circumferential tooth grooves 10 at the gear pitch circle are equal. The first shaft 1, the second shaft 6, the intermediate shaft 4 and the gear are installed in the housing 2 through bearings. The constant mesh gear 3 is installed on the first shaft 1, and the reverse gear 5 is installed on the second shaft 6. Through different The gear transmission ratio realizes the speed change (the speed change principle of the present invention is identical with the existing automobi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com