Polymer particles, process for production thereof, resin compositions containing the particles, and moldings

A technology of resin composition and polymer, which is applied in the direction of diffusion elements, etc., can solve the problems of large polymer particle constraints and difficulty in quality adjustment, and achieve the effects of less structural constraints, less powder flying, and excellent powder properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0084] (Method for producing polymer microparticles (A))

[0085] As a method of polymerizing the above-mentioned polymer microparticles (A), it is preferable to first prepare a suspending and dispersing agent containing a polymerizable monomer, a water-insoluble substance, an oil-soluble polymerization initiator, an emulsifier, and / or a water-soluble polymer compound, and water. The mixed liquid, then, apply mechanical shear to the mixed liquid to prepare O / W type emulsion, then, after introducing the O / W type emulsion thus prepared into the polymerization device, further make the O / W type emulsion under the condition of rising temperature The method to perform the aggregation.

[0086] When preparing this emulsion, in order to control the particle size of the O / W type emulsion, it is preferable to use a dispersing device that can adjust the shear strength, and to carry out while adjusting the strength. In addition, it is more preferable to carry out cooling operation at the ...

Embodiment

[0220] Hereinafter, specific examples are given and described, but these are examples and do not limit the content of the present invention at all.

[0221] (various measurement methods)

[0222] First, various measurement methods described below will be described.

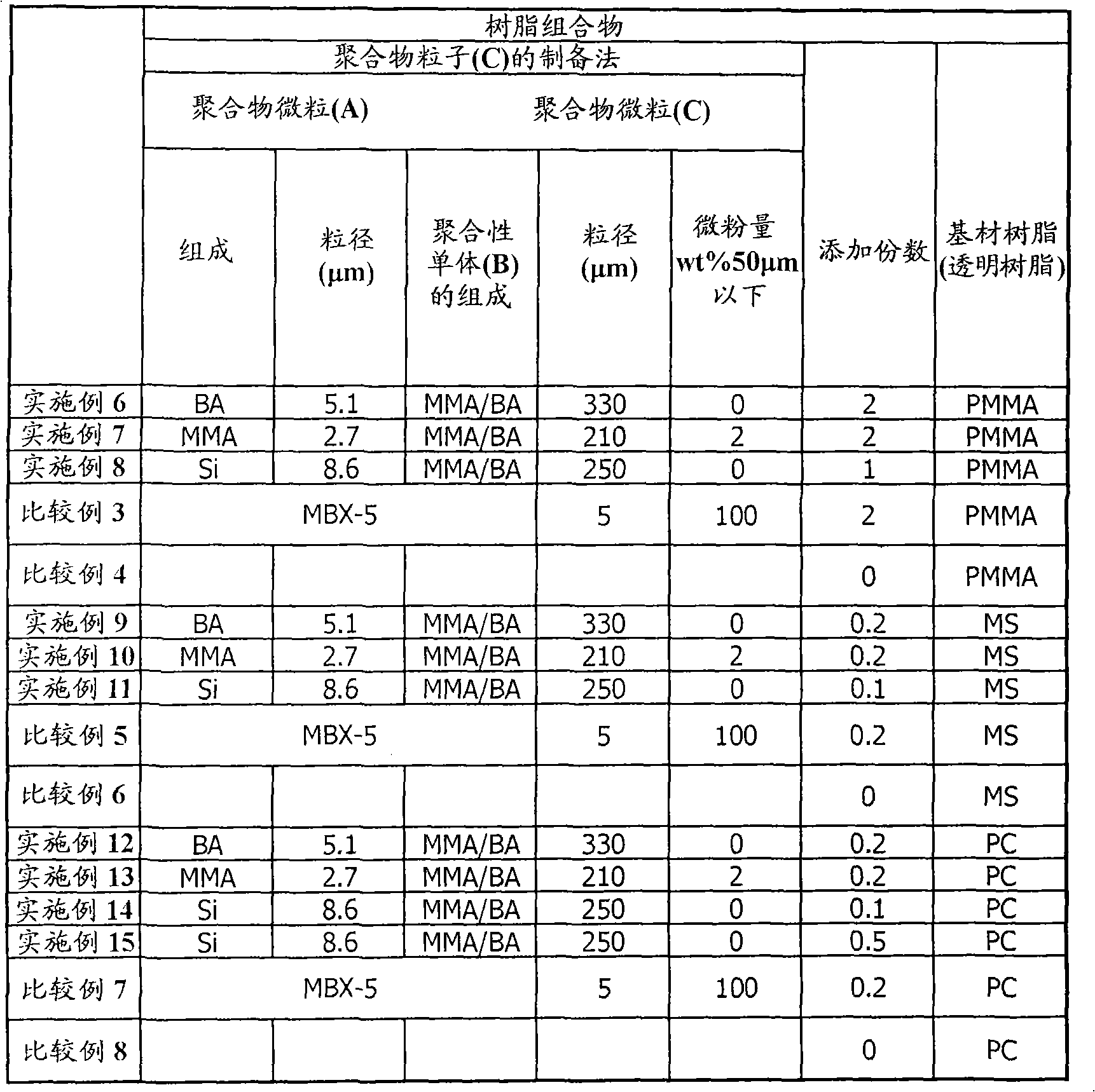

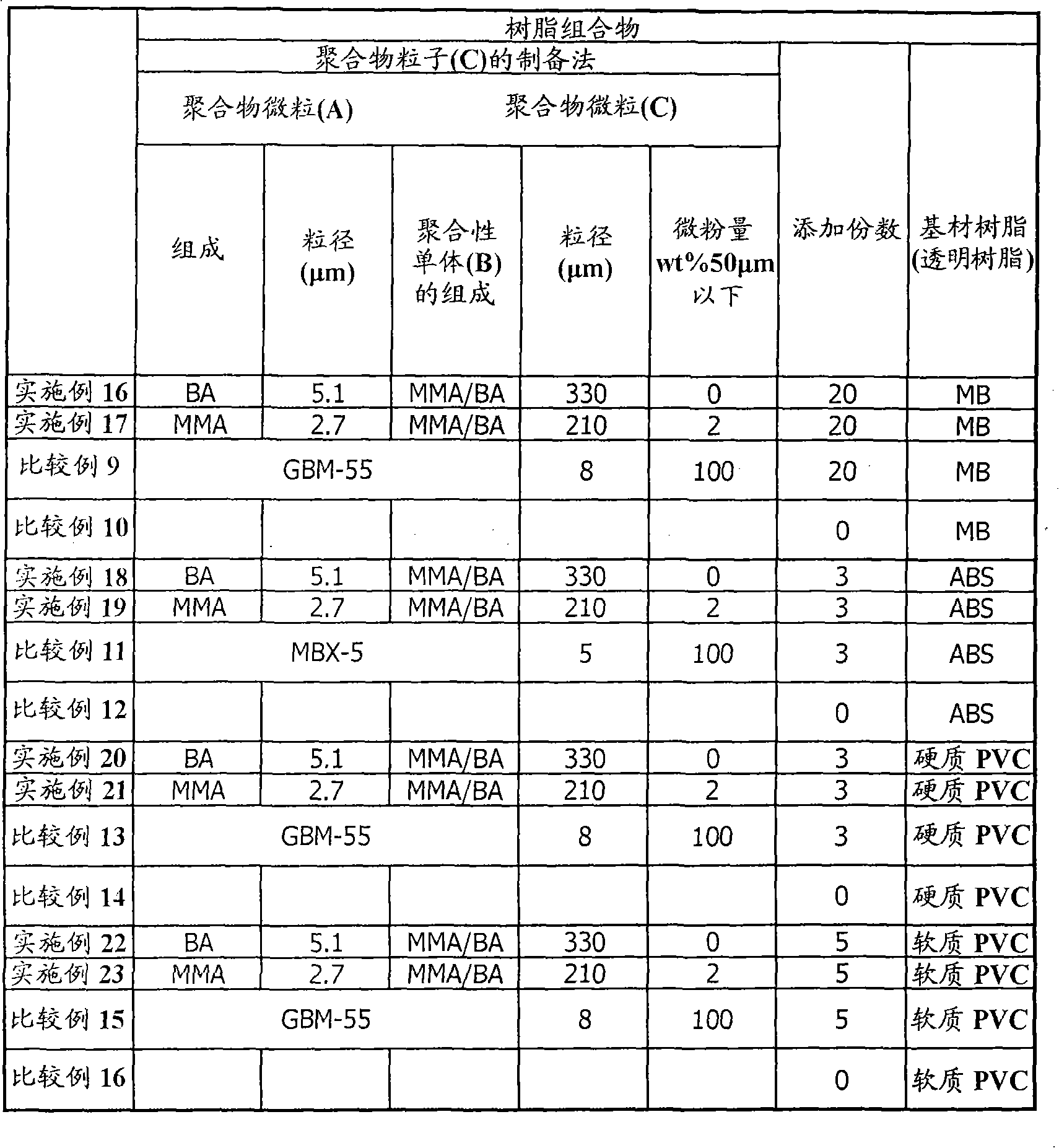

[0223] The measurement of the volume average particle size and the amount of fine powder below 50 μm is based on the measurement method specified in JIS Z8901, by observing with a micro-track particle size analyzer Model 9220FRA (manufactured by Nikkiso Co., Ltd.) or an optical microscope, and randomly selected 100 Particle image analysis is carried out.

[0224] In addition, the degree of turbidity of the filtrate after polymerization of the matting polymer particles (C) was confirmed by observing the filtrate of the slurry obtained by filtration using qualitative filter paper No. 2 manufactured by Advantech Toyo Co., Ltd.

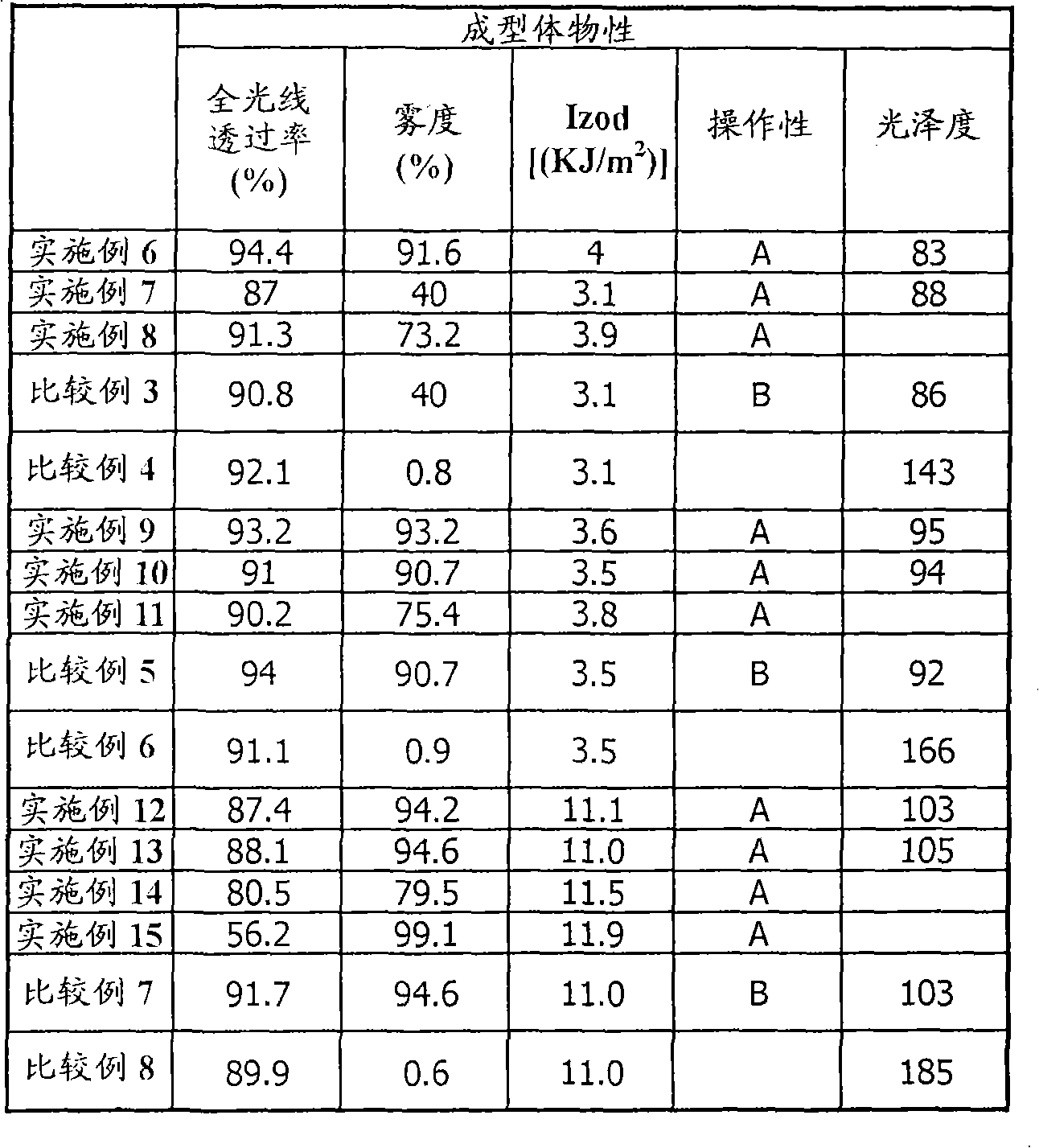

[0225] The light transmittance was evaluated by measuring the total light transmittance...

preparation example 1

[0249]

[0250] The methyl methacrylate-butyl acrylate copolymer (MB) used in Examples 16 and 17, and Comparative Examples 9 and 10 was prepared by the following method.

[0251] That is, after adding 220 parts by weight of water and 15 parts by weight of a 3% by weight aqueous solution of polyvinyl alcohol (GH-20: manufactured by Nippon Synthetic Chemical Industry Co., Ltd.) to a reactor equipped with a stirrer, the inside of the reactor was replaced with nitrogen gas. . Added therein containing 90 parts by weight of methyl methacrylate dissolved with 0.5 parts by weight of lauroyl peroxide and 0.5 parts by weight of benzoyl peroxide, 10 parts by weight of butyl acrylate and 0.8 parts by weight of tertiary dodecyl mercaptan For the monomer mixture, adjust the rotation speed of the mixer so that the dispersed particle size of the monomer is about 250 μm. Then, the polymerization was completed by heating at 60° C. for 2 hours, 70° C. for 2 hours, 80° C. for 2 hours, and 90° ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com