Automatic liquor removing workstation

A workstation and pipetting technology, applied in instruments, laboratory utensils, analytical materials, etc., can solve the problems of poor stability and repeatability of sample processing, high cost of accessories and consumables, low precision and stability, and achieve sample processing The results are stable and reliable, the structure is compact, and the effect of optimizing the mating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

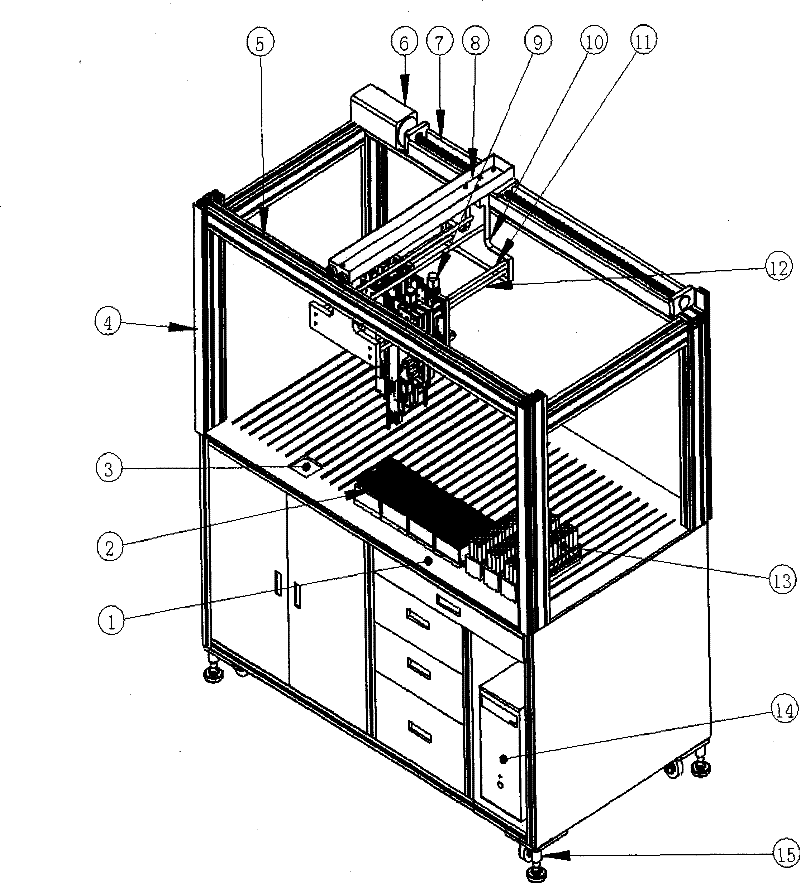

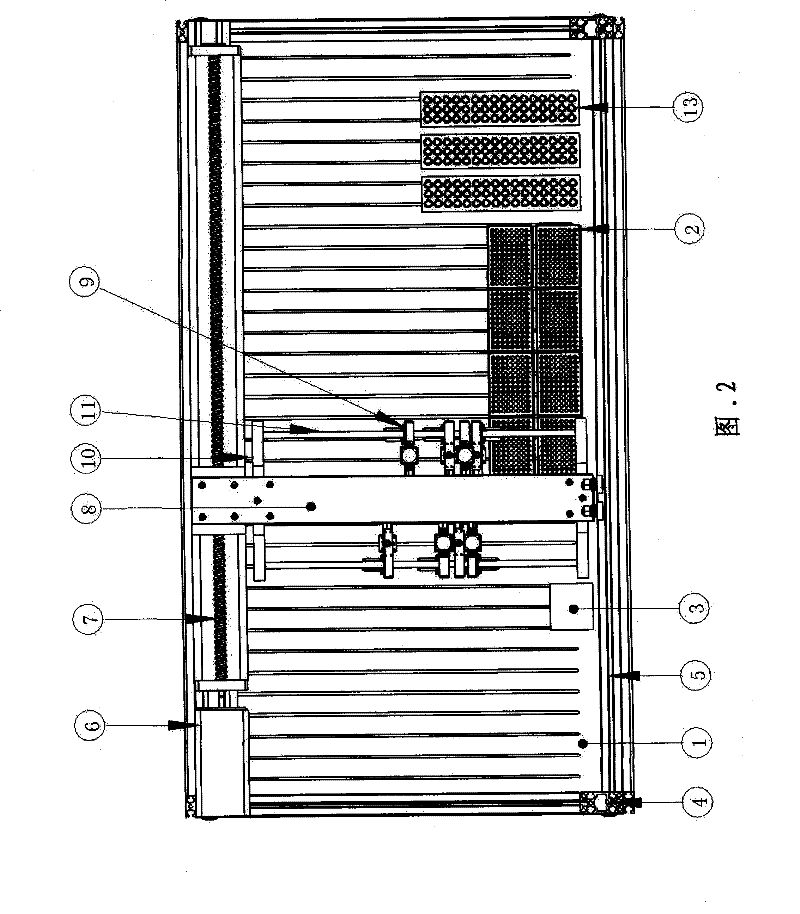

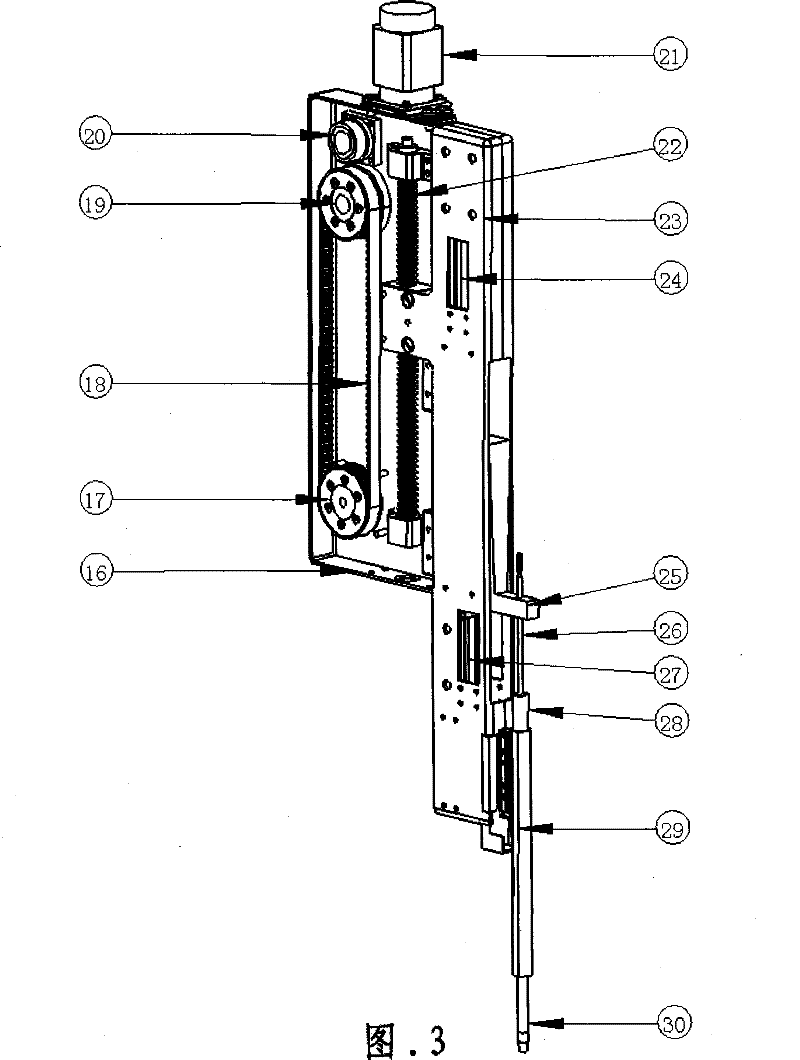

[0032] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

[0033] As shown in the figure, (1) is the working platform, (2) is the tip storage module, (3) is the tip recovery area, (4) is the support frame, (5) is the X-axis auxiliary guide rail, (6) is the X-axis driving motor, (7) is the X-axis electronically controlled translation platform, (8) is the Y-axis beam support, (9) is a manipulator module, (10) is the connecting frame, (11) and (12) the Y-axis direction Guide pillars and screw rods used for motion, (13) is a sample storage module, (14) is a computer, (15) is an adjustable caster group, (16) is a fixed bracket A, used to install the Y-axis direction motion drive motor (17), Y-axis direction drive nut (19), guide column overcoat (20), Z-axis drive motor (21) and Z-axis motion mechanism (22), etc., (17) is the drive motor for Y-axis direction motion, ( 18) is a synchronous belt, (19) is a drive nut in the Y-axi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com