Method of manufacturing mask for semiconductor device

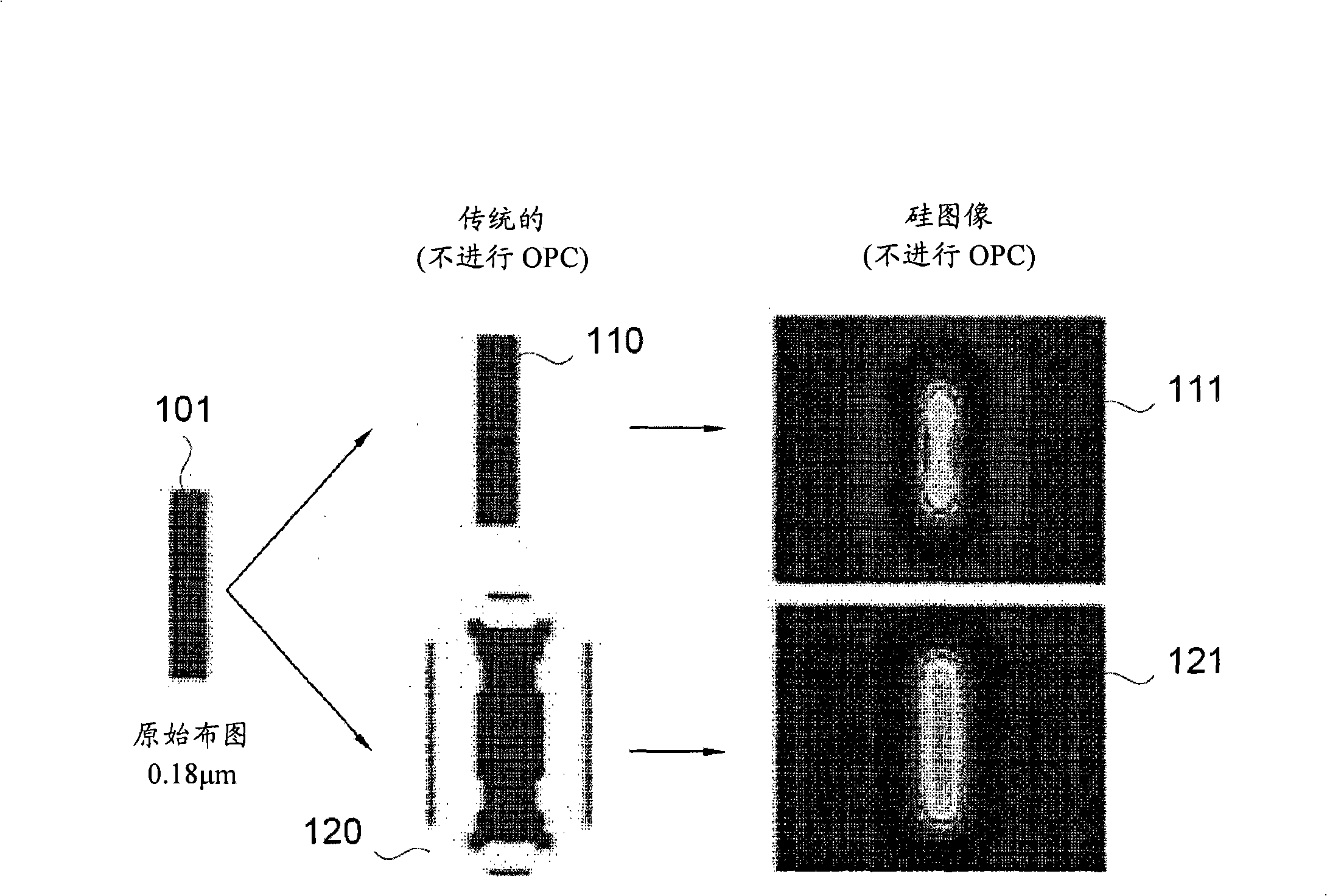

A semiconductor and mask technology, used in semiconductor/solid-state device manufacturing, originals for opto-mechanical processing, and photolithography processes for patterned surfaces, which can solve the degradation of wafer yield, the impact of production time, and the increase in time consumption and cost. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

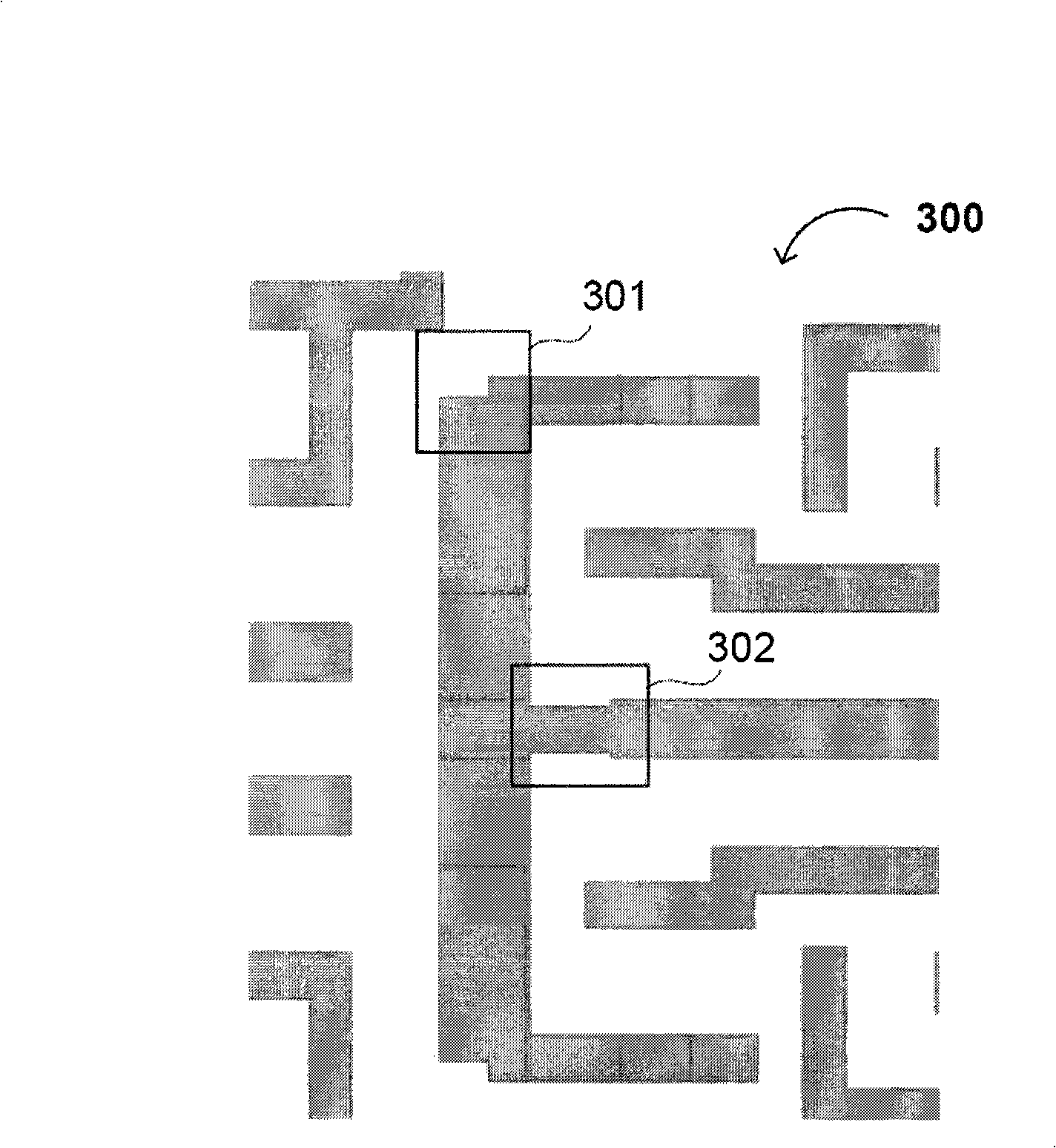

[0038] Preferred embodiments and examples of the present invention will be described in detail with reference to the accompanying drawings. Wherever possible, the same reference numbers will be used throughout the drawings to refer to the same or like parts.

[0039] Figure 4 is a flowchart illustrating an exemplary method of fabricating a mask using optical proximity correction a1 (OPC). First, a design database input step (S402) is implemented to input the design database into the mask manufacturing process. For example, after tape-out, the design database can be transferred to a semiconductor manufacturing facility (FAB) to implement the process based on the FAB's manufacturing capabilities.

[0040] Implement the design rule detection (DRC) step (S404), whether the input data of detection layout exceeds (drawn) the design rule that follows, if find the design error against this design rule or implement the layout correction step (S406) that violates the rule and correct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com