Method for producing magnetic steel molding product by full-automatic wet process and molding machinery thereof

A fully automatic, wet technology, applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve problems such as sintering cracks or cracks, lack of sealing effect, and difficult setting of sealing rings, etc., to achieve consistent product density , Prolong the service life of the mold and shorten the pressing molding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

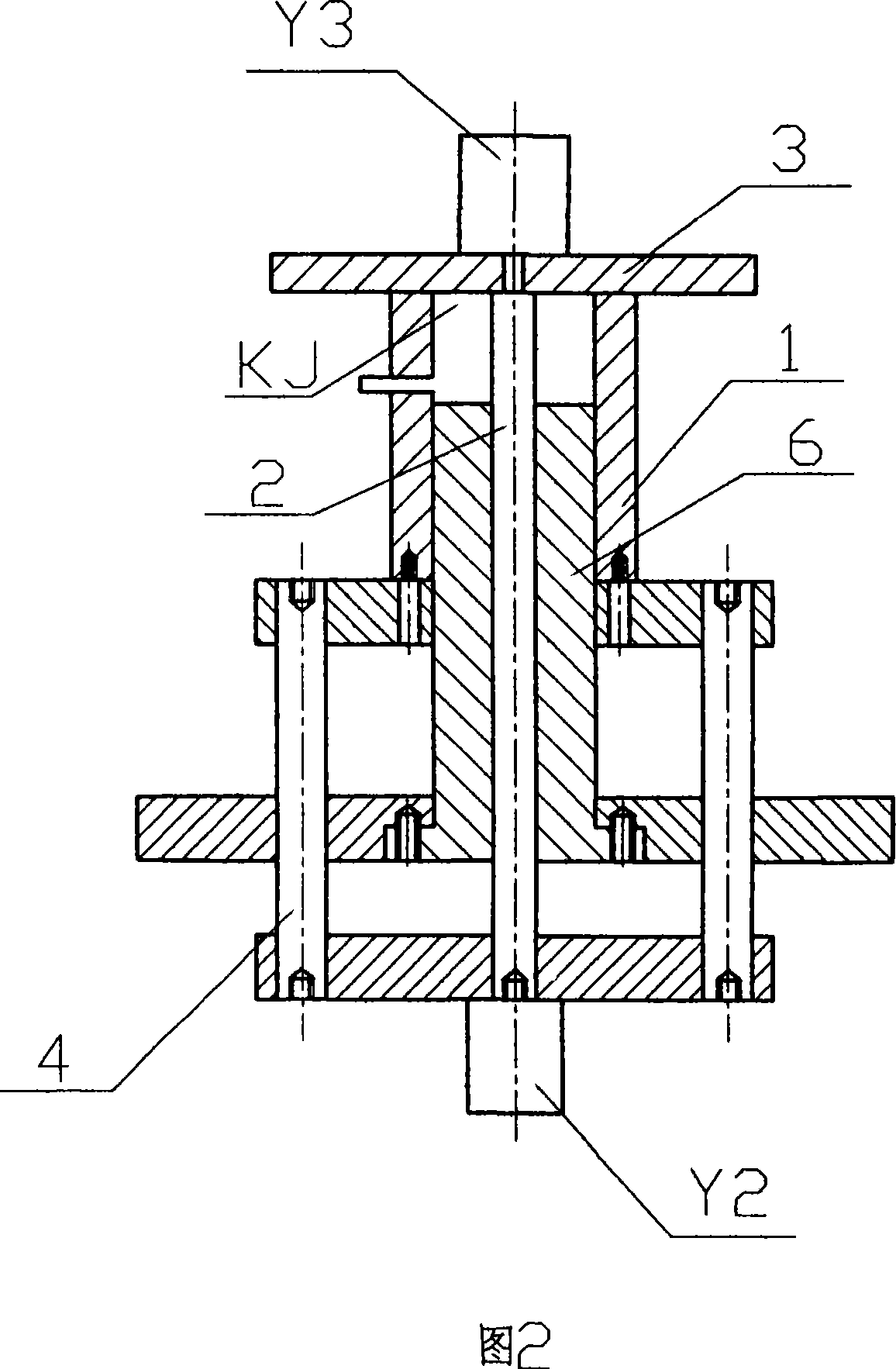

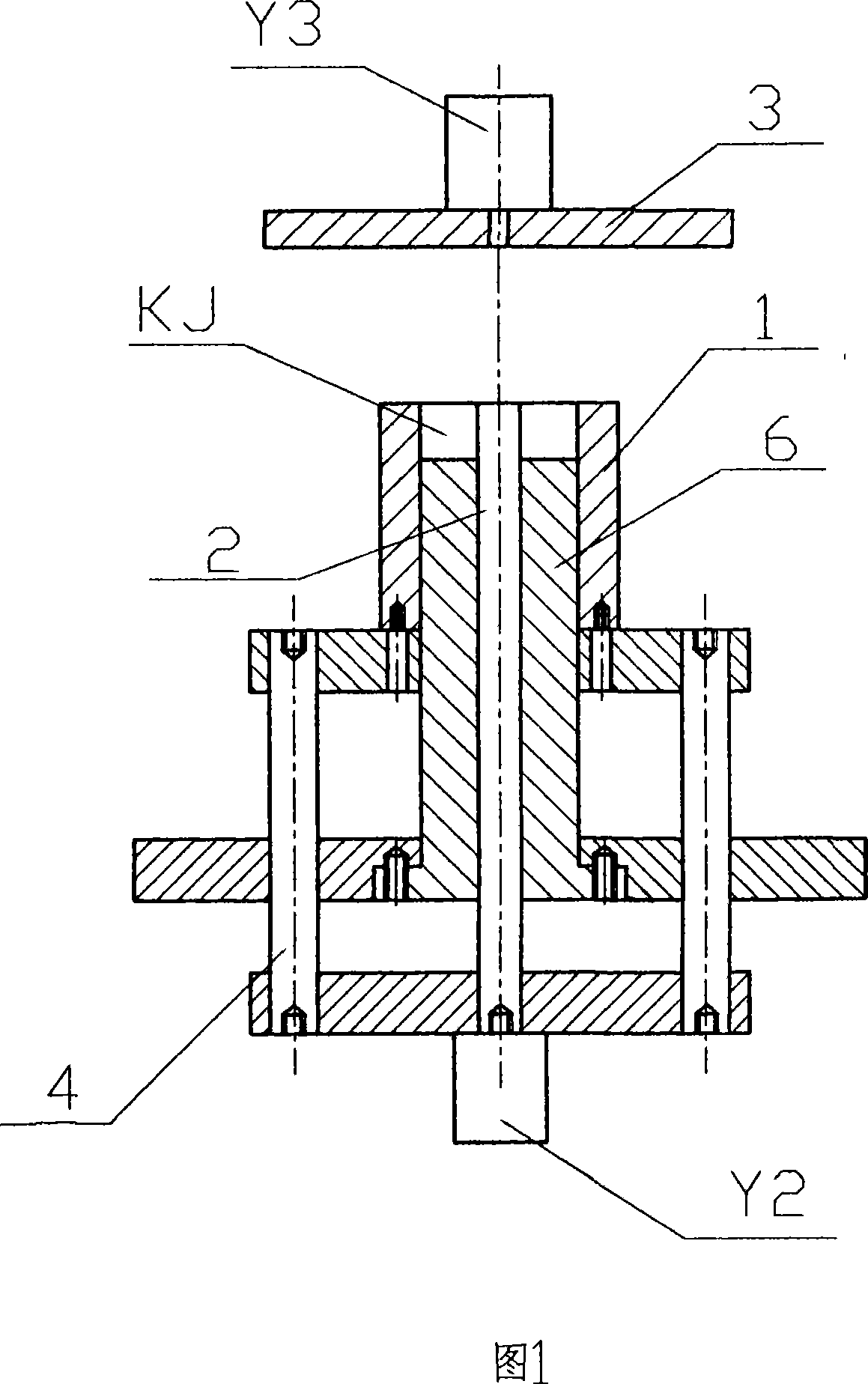

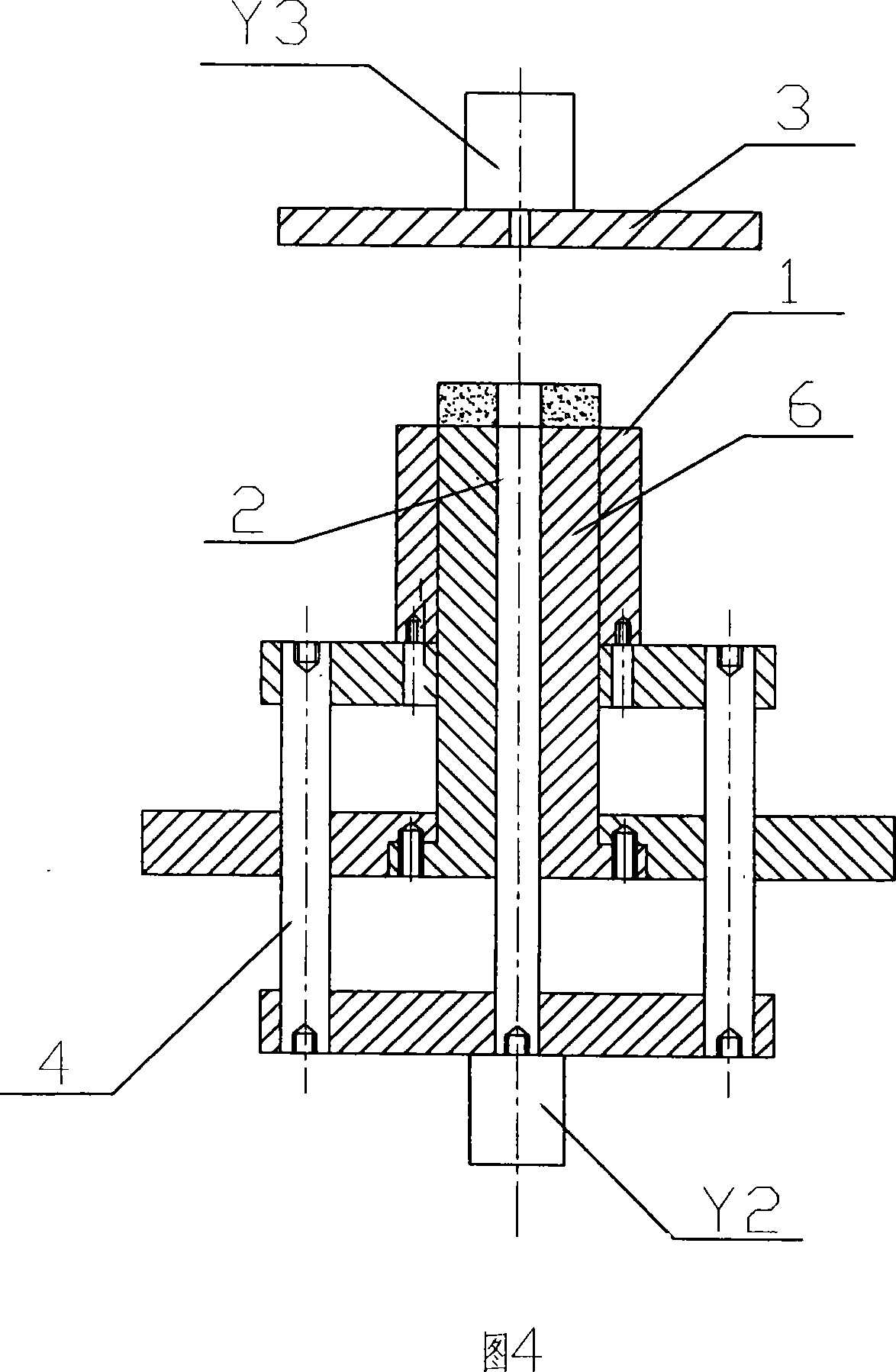

[0030] The method for fully automatic wet production of magnetic steel shaped products of the present invention comprises the steps of preparing slurry, pressing and forming a green body, sintering the green body into a blank and processing the green body into a product after the blank, and the pressing and forming green body is a wet method for producing a magnetic steel shaped product The core process step of the method, the automatic feeding and pressing molding step of the current existing technology, although it is feasible in theory, but because the upward and downward movements of the cavity and the core rod are always linked, the top is always flush and at the same level position, the feeding port is set on the inner wall of the cavity, and feeding from the side is difficult to implement in actual production; because the automatic feeding method is difficult to implement, in the current production, semi-automatic production with manual feeding is still commonly used cra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com