Method for preparing immobilization cold resistant strain

A cold-resistant, bacterial strain technology, applied in the direction of biochemical equipment and methods, chemical instruments and methods, and microbial-based methods, can solve the problems of slow growth and low removal rate of organic pollutants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0009] Specific embodiment one: the preparation method of immobilized psychrotrophic bacteria in this embodiment is as follows: 1, the cultivation and domestication of bacterial classification: put the sludge in the aeration tank of winter sewage treatment system into the low-temperature biochemical culture that temperature is 15 ℃ In the tank, the mixed sewage composed of domestic sewage and simulated sewage at a volume ratio of 1:1-3 is introduced, and then the sludge concentration is 2.0-3.0g / L, and the dissolved oxygen is 2-4mg / L. Expose the sludge for 8-10 hours, then settle for 2-4 hours, then change the water once a day and then discharge 1 / 3 of the supernatant, and discharge all the supernatant after 2-4 days of operation, and then put it in the water with a hydraulic retention time of 6 -8h, under the condition of 2-4h static settling time, lower the temperature of the low-temperature biochemical incubator to 10°C for 8-10 days, then lower it to 8°C for 8-10 days, and ...

specific Embodiment approach 2

[0011]Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that 6 bacterial strains were screened out in step 2. After testing, these 6 bacterial strains belonged to the genus Kineticum, Aeromonas, Flavobacterium, and Microbacteria, respectively. Bacteria, Bacillus and Pseudomonas. Others are the same as in the first embodiment.

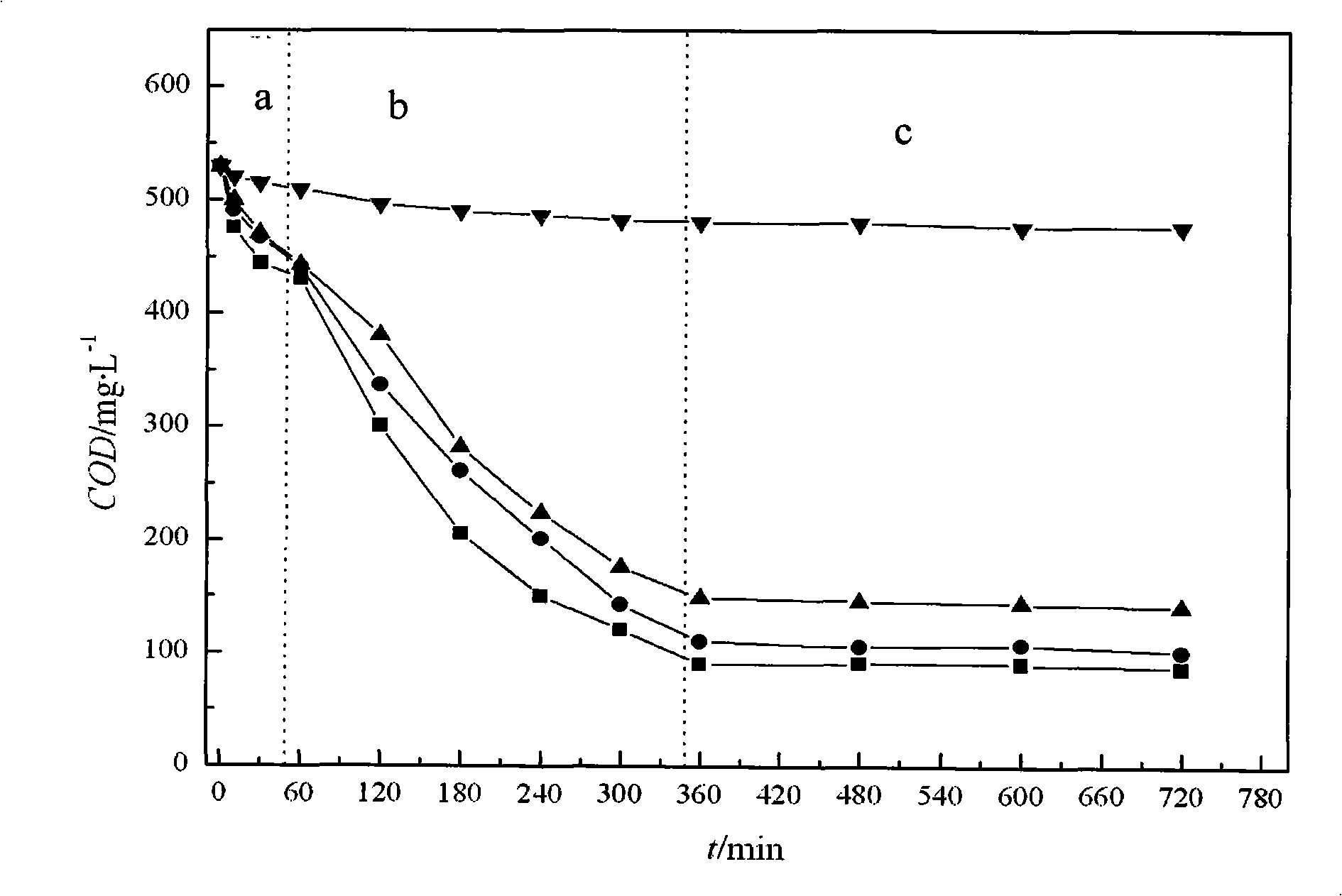

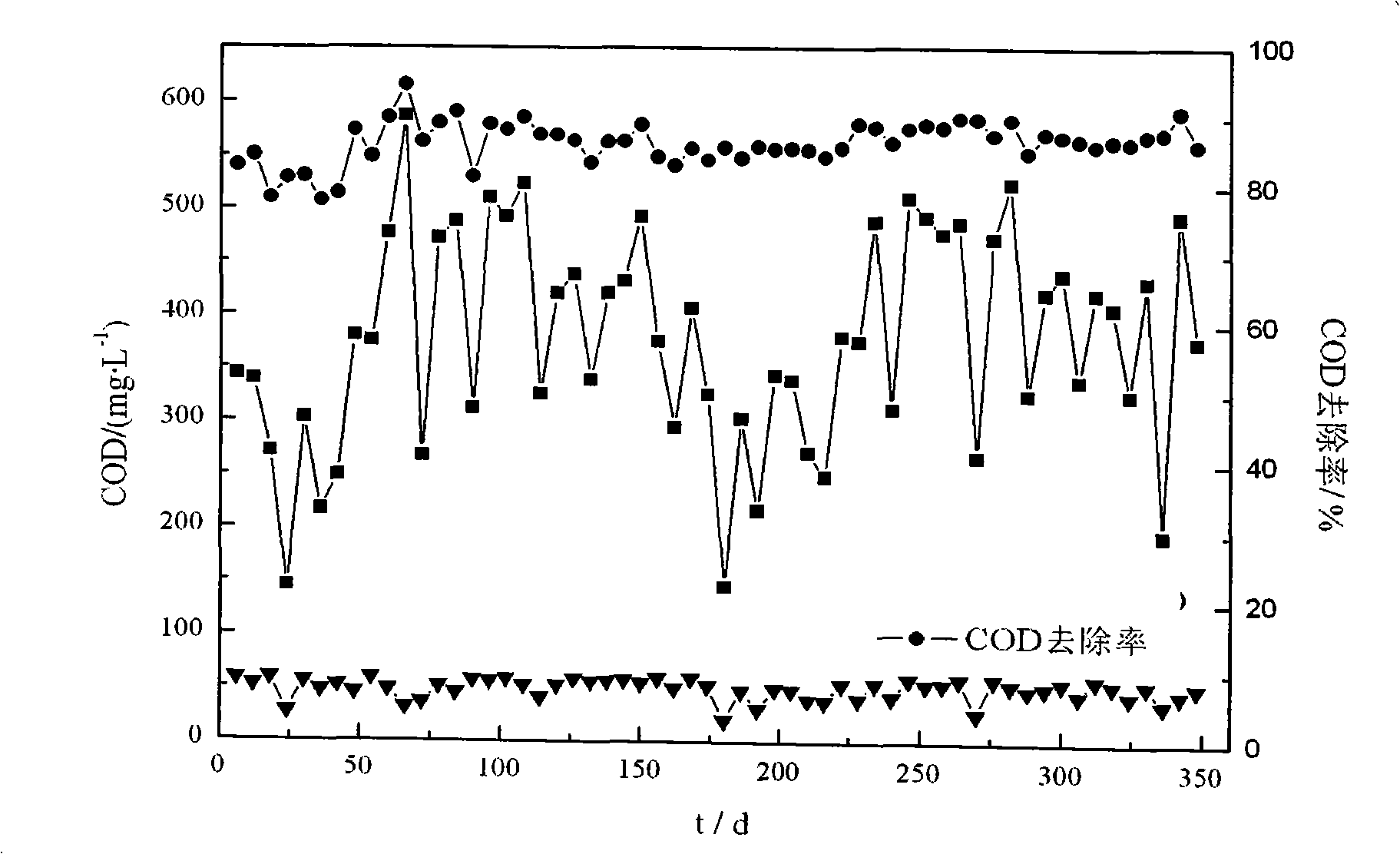

[0012] The immobilized psychrotrophic bacteria obtained in this embodiment were tested in a composite bioreactor, and the sewage was treated in the composite bioreactor successively through two treatment processes: activated sludge treatment and biological contact oxidation treatment, wherein activated sludge treatment During the process, the sludge concentration is 2.0-3.0g / L, the dissolved oxygen concentration is 2.0-4.0mg / L, and the immobilized psychrophilic bacteria obtained in this embodiment are added to the composite In the bioreactor, the dosage of immobilized psychrophilic bacteria is 25-35% of the effe...

specific Embodiment approach 3

[0015] Embodiment 3: This embodiment differs from Embodiment 1 in that the sludge concentration in step 1 is 2.1-2.9 g / L. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com