Far infrared hot pipe type vapor and water dual-purpose heating stove and method of use thereof

A heat-pipe, far-infrared technology, used in steam boilers, combustion methods, fluid heaters, etc., can solve the problems of low automation control, hidden dangers to user safety, and high energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

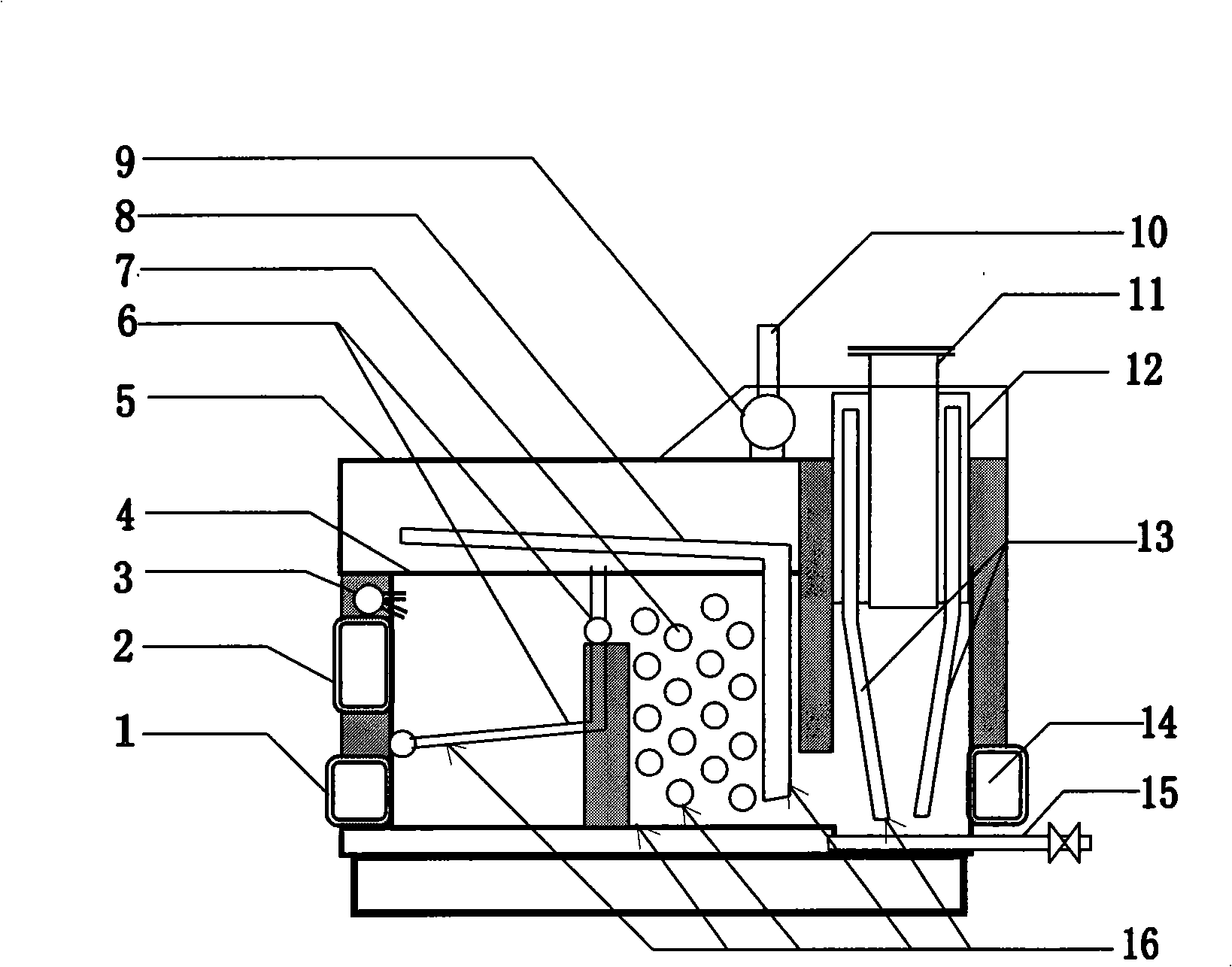

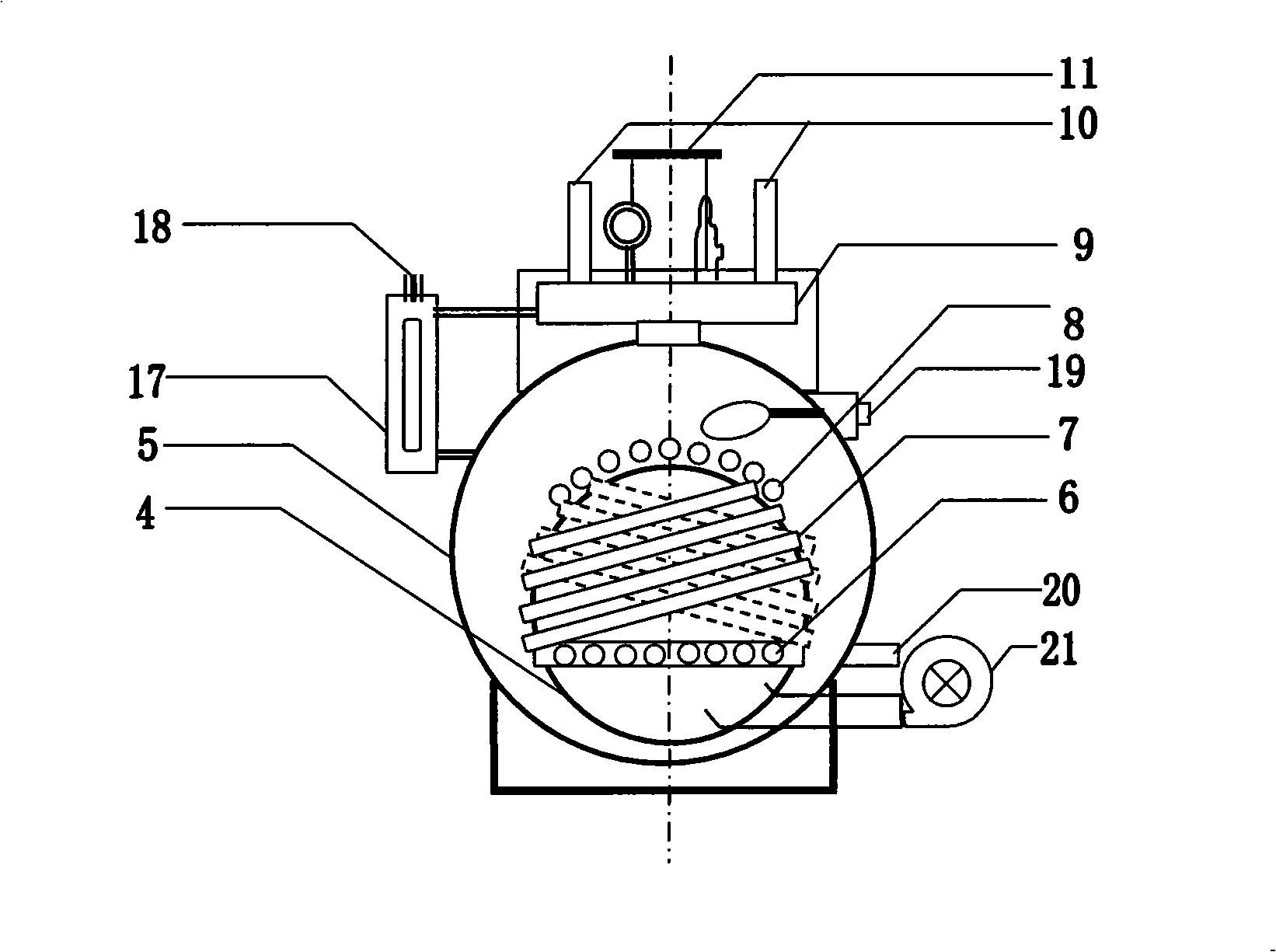

[0008] Before the operation of the present invention, the steam or water equipment and supporting auxiliary equipment are sealed and connected with the steam supply main pipe (9) of the heating furnace, so that the whole system is communicated with each other. After ignition and normal operation, the fuel burns in the furnace, and the softened water in the heat pipe type preheating water tank (12) is heated to boiled water by the smoke pipe (11) at the flue gas outlet and the dust-blocking special-shaped medium-temperature heat pipe (13) , by liquid level display and electromagnetic float switch (19), control water pump replenishment amount and replenishment time, replenish the boiled water after softening to this heating furnace through replenishment pipe (20). High-temperature pyrotechnics and flue gas pass through the inner drum (4), grate pipe and header (6), horizontal water circulation pipe (7), special-shaped high-temperature heat pipe (8) and far-infrared high-temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com