Method and device for testing the integrity of filtration membranes

A test method, integrity technology, applied in measurement devices, chemical instruments and methods, membranes, etc., can solve problems such as interference results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

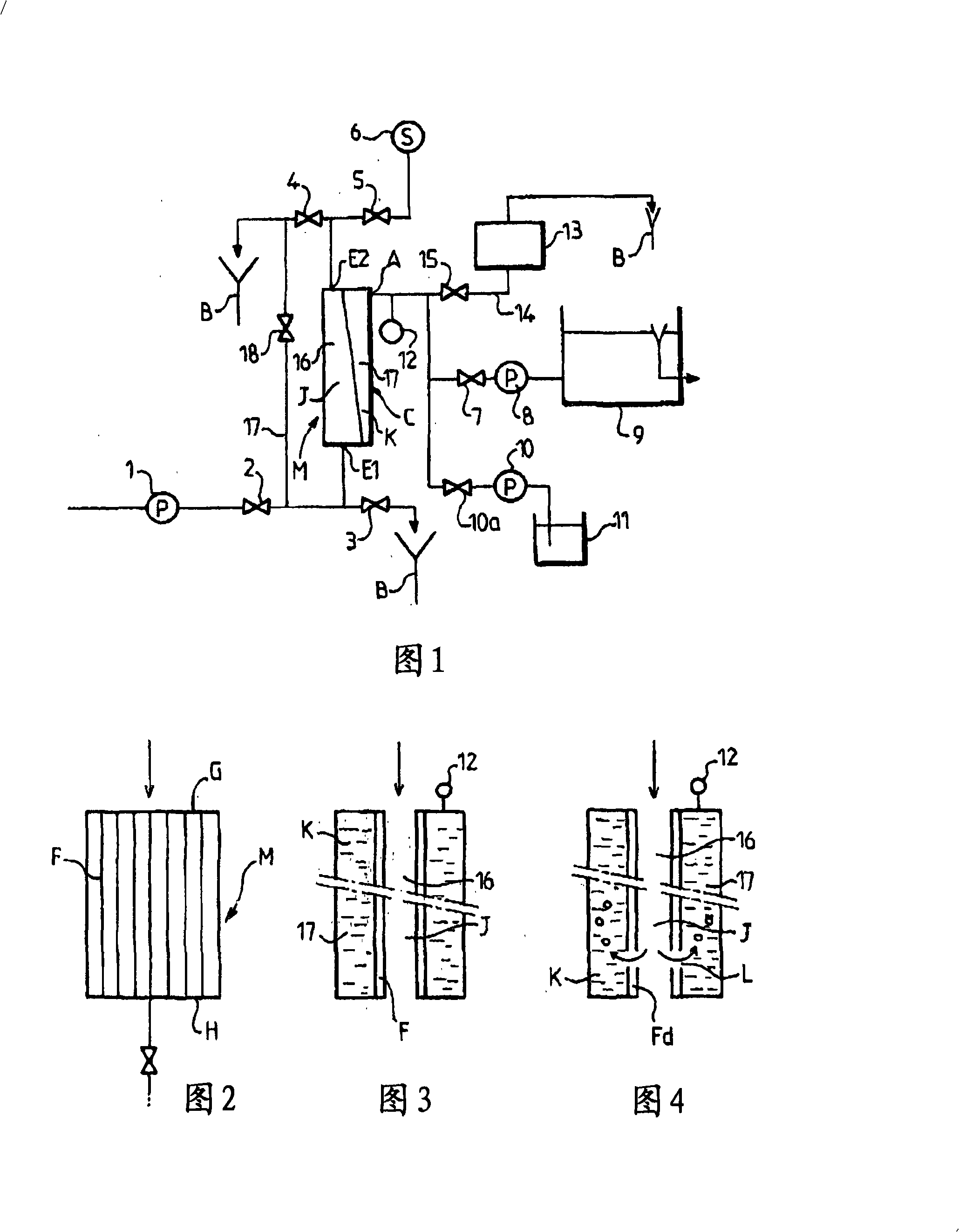

[0042] Figure 1 shows a filter device of the type described in patent application FR 2 867 394 (04 / 02492) carrying out the method of the invention, to the same company as the applicant of the present application.

[0043]The schematically shown module consisting of a housing C encloses an array M of filter membranes consisting of hollow fibers F with an inner skin ( FIG. 2 ). Each module M comprises several thousand hollow fibers F arranged in parallel between two manifolds G, H for delivery or collection, depending on the direction of flow.

[0044] The housing C has two openings E1 , E2 at the bottom and top respectively, which can be used as outlets and / or inlets. The openings E1 , E2 are connected to the concentrate chamber J formed by the hollow fiber inner space. Inside the housing, the space around and between the filter membranes forms a permeate chamber K with an outlet A.

[0045] The device comprises a pump 1 for supplying the liquid to be filtered, the discharge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com