High-accuracy thin and long circular axis processing method

A processing method and high-precision technology, applied in the field of mechanical processing, can solve the problems of long time occupation, low production efficiency, high manufacturing cost of slender round shaft racks, etc., and achieve the effect of easy realization and saving process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

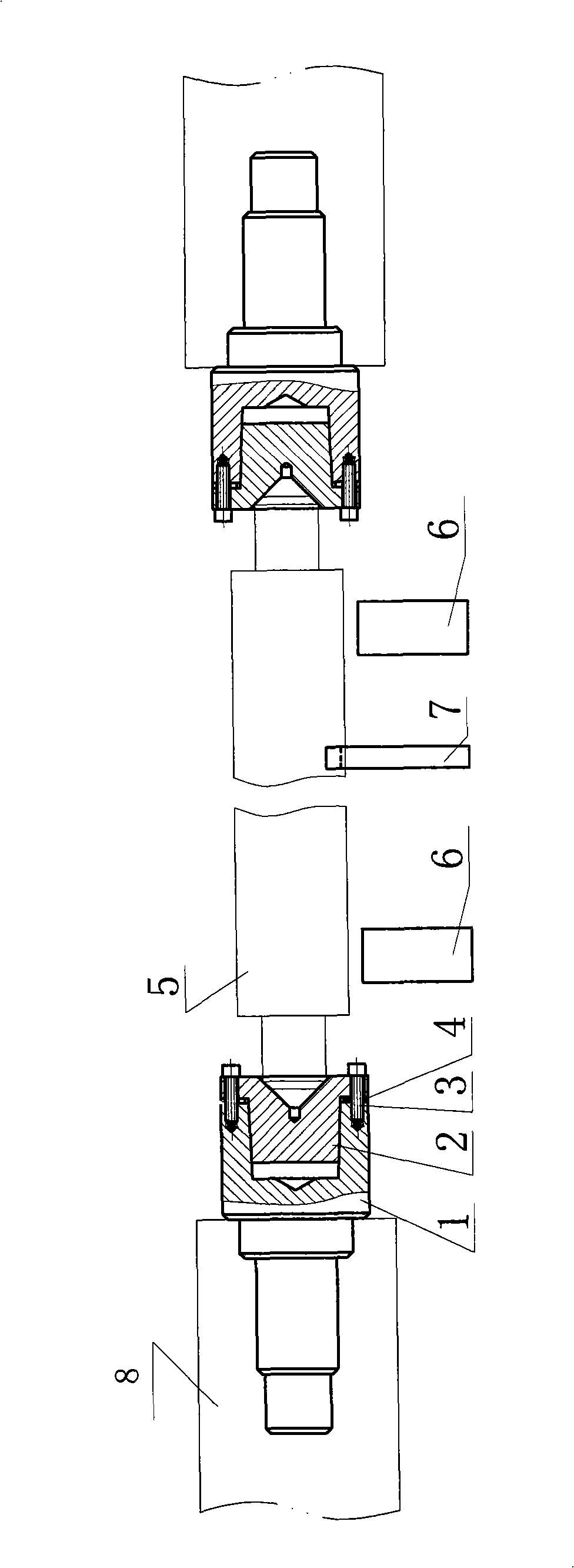

Image

Examples

Embodiment Construction

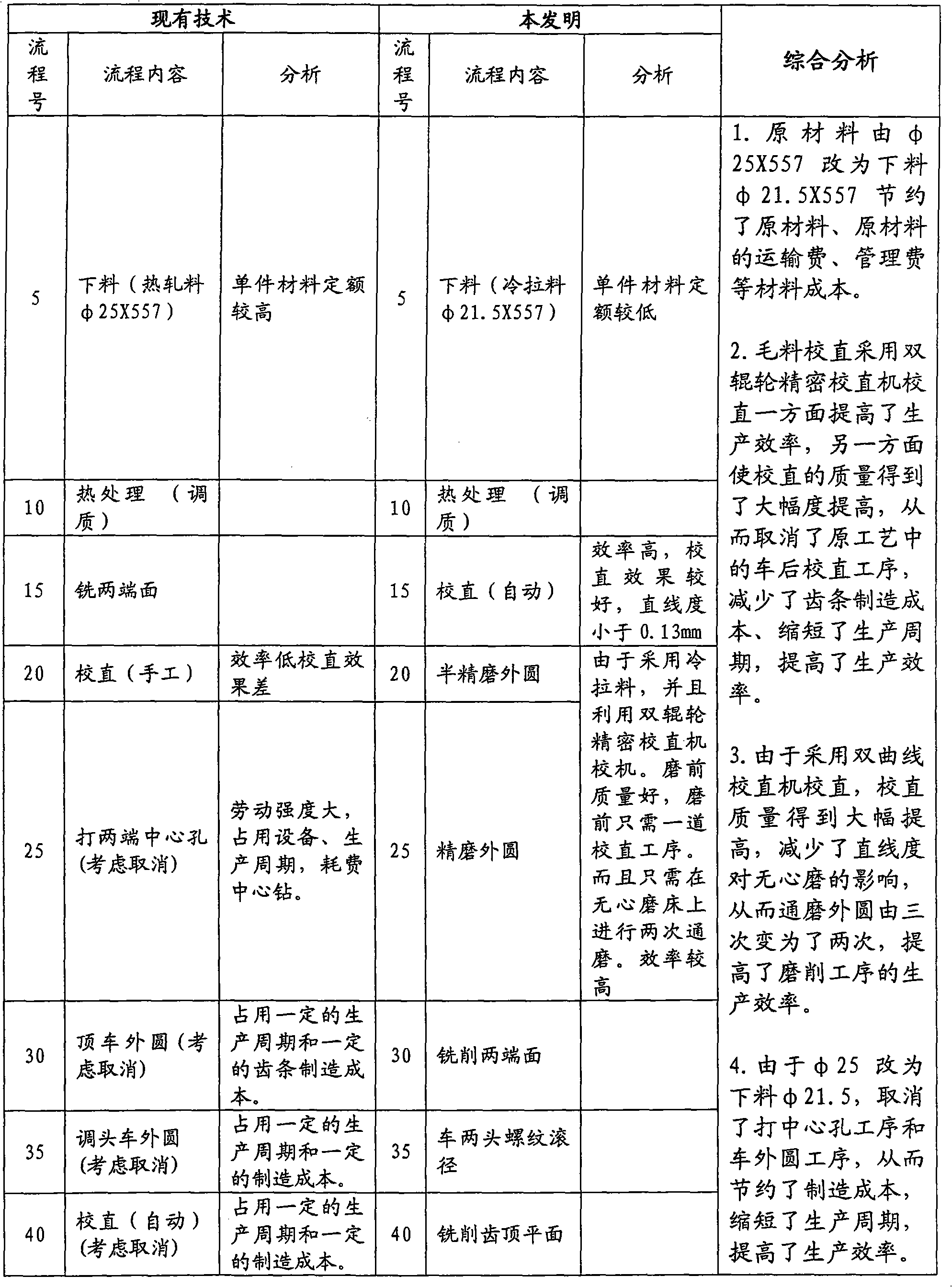

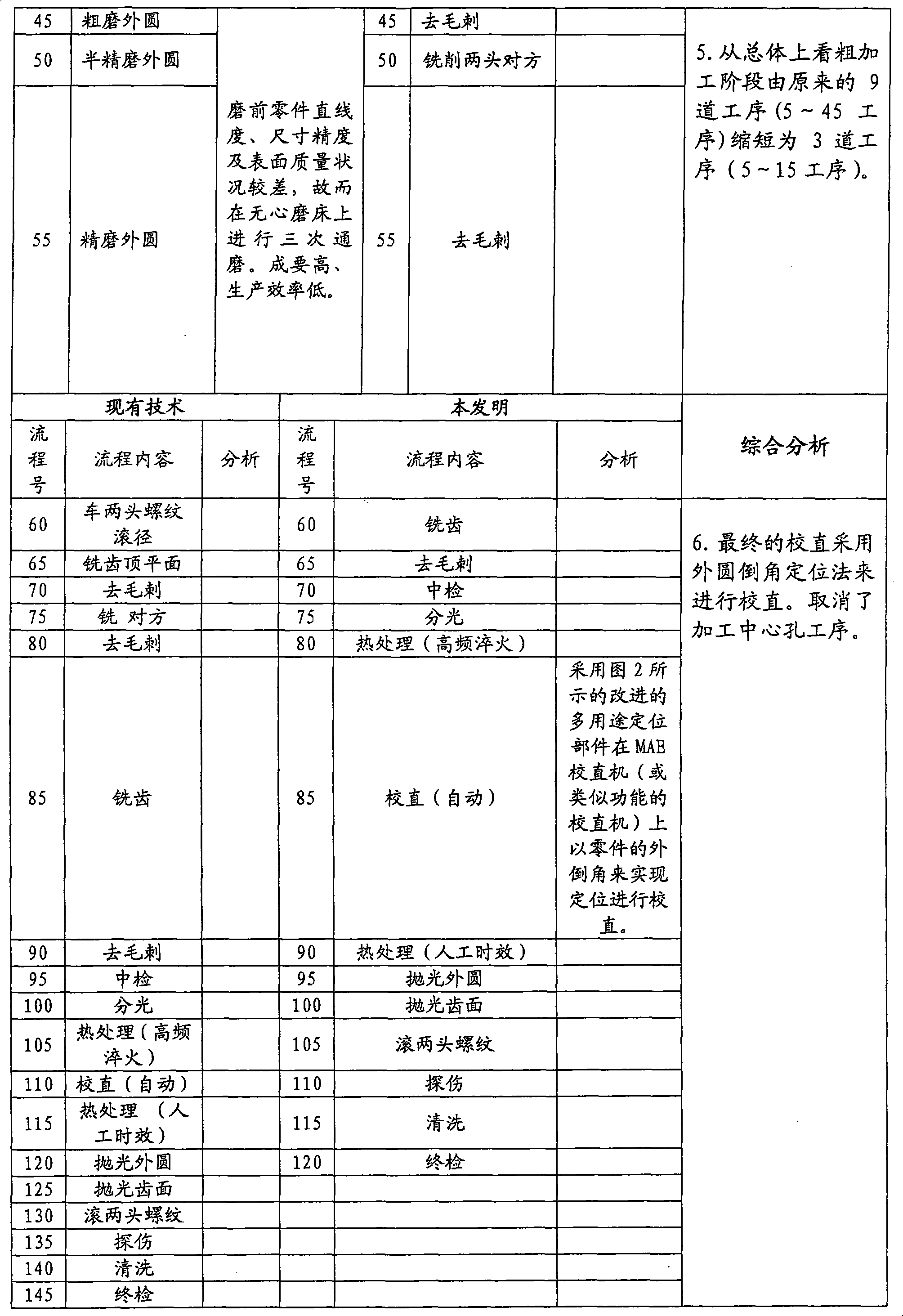

[0027] In the following, combined with the accompanying drawings and taking the production of slender circular shaft rack parts with the final dimension of the outer circle as φ21f5 (dimensional accuracy IT6), surface roughness of 0.8μm, straightness of 0.08mm, and rack precision of 7D H GB / T10096-1988 as an example , the features and effects of the processing method of the high-precision elongated circular shaft proposed according to the present invention are described in detail as follows:

[0028] a. Material selection: The rough material adopts cold-drawn material whose outer diameter is close to the outer circle of the final product (the outer circle of the final slender circular shaft rack is φ21, so the cold-drawn bar material of φ21.5 is selected);

[0029] b. Straightening of wool: In order to eliminate the bending deformation of rough blanks after quenching and tempering, and ensure the straightness requirements of slender shaft parts, use a double-roller precision st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com