Aluminum system flocculating agent preparing apparatus

An aluminum-based flocculant and production device technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problem of undiscovered supporting equipment, avoid acid mist pollution and harm to on-site personnel, realize automatic operation, reduce The effect of personnel operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

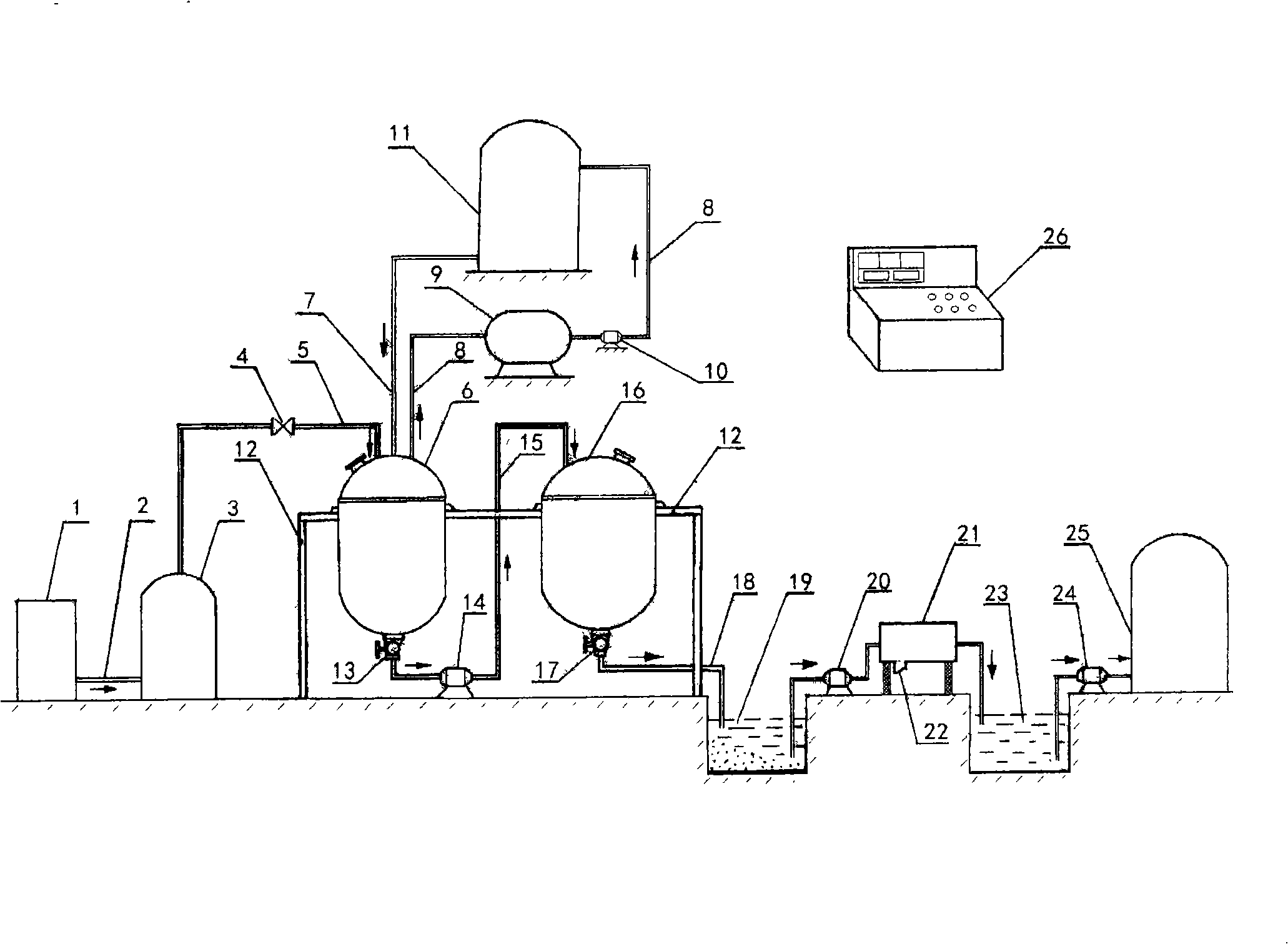

[0012] An embodiment is illustrated in conjunction with the accompanying drawings:

[0013] In the accompanying drawings, 1 is a natural gas storage tank, 2 is a natural gas pipeline, 3 is a gas-fired steam boiler, 4 is a steam valve, 5 is a steam pipeline, 6 is a reactor, 7 is an acid inlet pipeline, 8 is an acid recovery pipeline, and 9 is Acid recovery tank, 10 is the acid recovery pump, 11 is the acid storage tank, 12 is the indoor operation platform of the reactor, 13, 17 is the discharge valve, 14 is the material delivery pump, 15 is the material delivery pipeline, 16 is the regulating tank, 18 is the discharge pipeline, 19 is the settling aging tank, 20 is the feeding pump, 21 is the centrifugal solid-liquid separator, 22 is the solid impurity outlet of the separator, 23 is the drug storage tank, 24 is the product delivery pump, 25 is the product storage Tank, 26 is the operation control cabinet.

[0014] As shown in the drawings, the aluminum-based flocculant producti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com