Solar optoelectronic template and its packaging method

A technology of solar cell panels and packaging methods, applied in photovoltaic power generation, circuits, electrical components, etc., can solve the problems of solar photoelectric templates, high equipment performance requirements, and affecting product performance, and achieve good transparency, large light-receiving area, Ease of transport

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

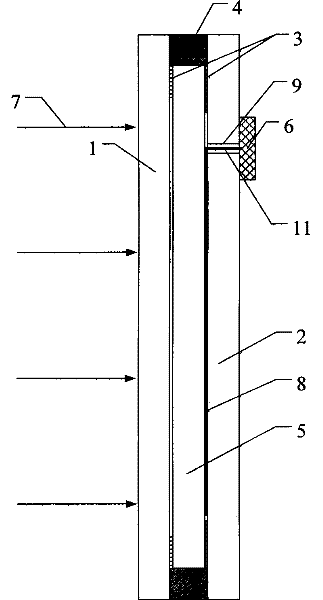

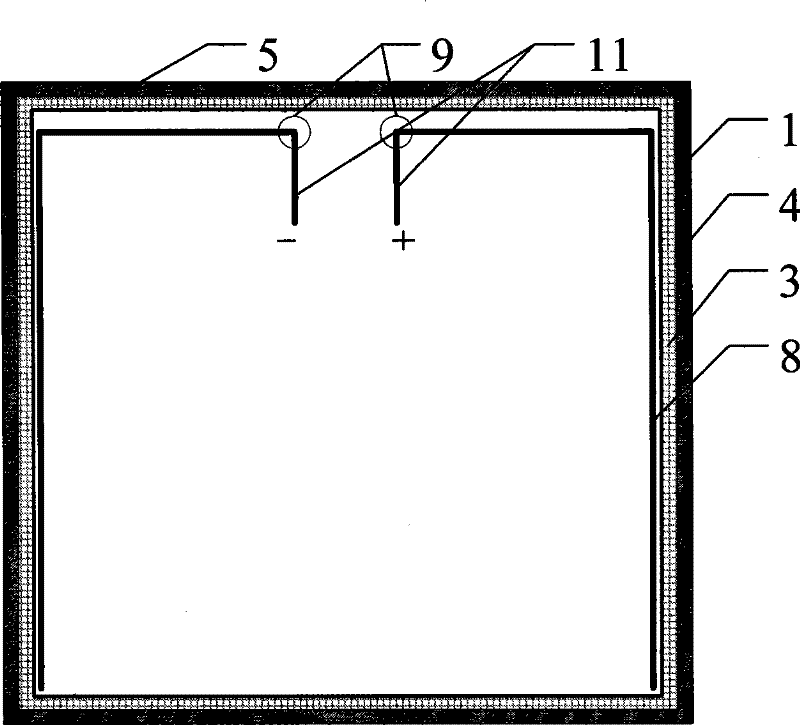

[0034] See Figures 1 to 7 , the photoelectric template includes a solar cell 5, an encapsulation insulating layer and an electrode lead-out wire 11, and a solar cell panel is formed by connecting several solar cells 5 in series and in parallel, and the inner and outer packaging of the solar cell 5 with a sealant layer 3 on the edge and the encapsulation insulating layer The surfaces of layers 2 and 1 are tightly bonded. The positive and negative electrodes of the solar cell 5 are respectively connected in series and in parallel with conductive strips 8. The electrode leads 11 of the conductive strips 8 are drawn out from the lead-out holes 9, and the junction box 6 is installed on the lead-out electrodes. Lead wire 11 above.

[0035] The part of the conductive tape 8 crossing each solar cell unit and the back electrode of the solar cell 5 needs to be insulated, for example, coated with a layer of insulating polyester (Polythylene terephthalate, PET).

[0036] The sealant lay...

Embodiment 2

[0046] Figure 8 A packaging method for a solar photoelectric template is shown, in which the solar panel is packaged together with a sealant, an encapsulation layer, and a structural adhesive, and the packaging steps are as follows:

[0047] Apply sealant 3 at the edge of the surface where the inner and outer encapsulation layers 2 and 1 are attached to the solar cell 5;

[0048] Add desiccant on the back or around the solar photovoltaic template;

[0049] Bonding the solar cell 5 to the inner and outer encapsulation layers 2 and 1 with pressure;

[0050] Structural glue 4 is used to inlay the inner and outer encapsulation layers 2, 1 and the peripheries of solar cells 5.

[0051] Wherein, there is also a positioning template on the outer packaging layer 1, and the solar cell 5 is positioned in the positioning template, and at least two or more solar cells 5 packaged in the inner and outer packaging layers 2 and 1 are connected in series, and the positive and negative elect...

Embodiment 3

[0053] A method for encapsulating solar photoelectric templates, the encapsulation steps are as follows:

[0054] The solar panel 5 is an amorphous silicon solar cell, and there will be at least one solar cell 5, and a sealant layer 3 is arranged on the edge of the cell 5;

[0055] Inner and outer encapsulation layers 2 and 1 covering the insulation are tightly pressed together;

[0056] The desiccant is sealed around the solar cell (5);

[0057] The structural adhesive 4 is embedded around the inner and outer encapsulation layers 2 and 1 and the solar cell 5 .

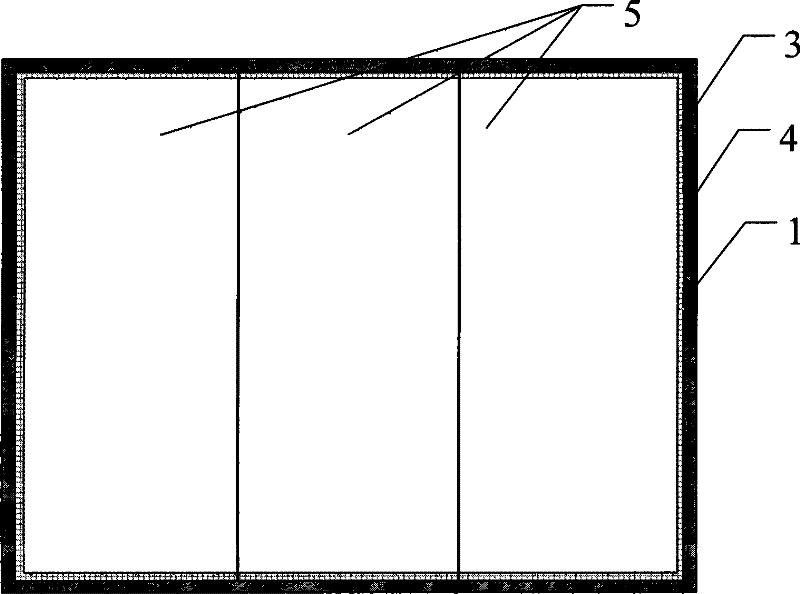

[0058] Wherein, there is also a positioning template on the outer encapsulation layer 1, and the amorphous silicon solar cell 5 is positioned in the positioning template, and at least two or more amorphous silicon solar cells 5 encapsulated in the inner and outer encapsulation layers 2 and 1 are connected in series internally. The positive and negative electrodes of the adjacent battery 5 are connected by a pluralit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com