Preparation of MgO nano particle material

A technology of nanoparticles and particles, applied in the direction of magnesium oxide, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

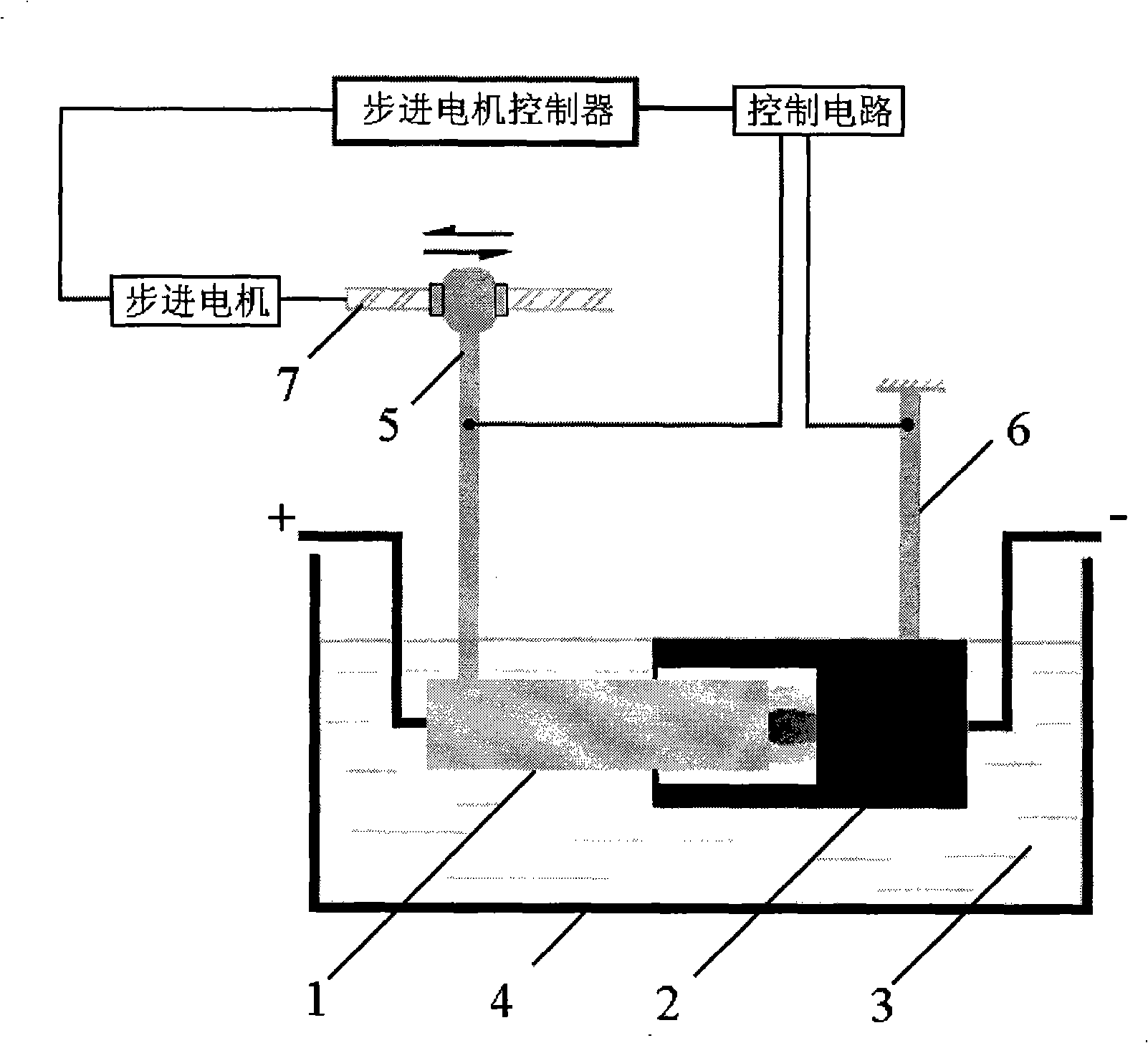

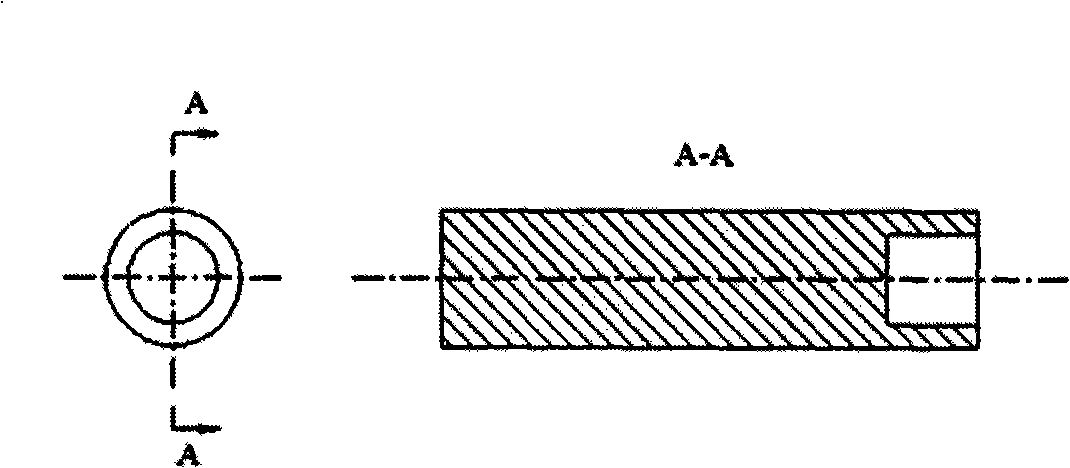

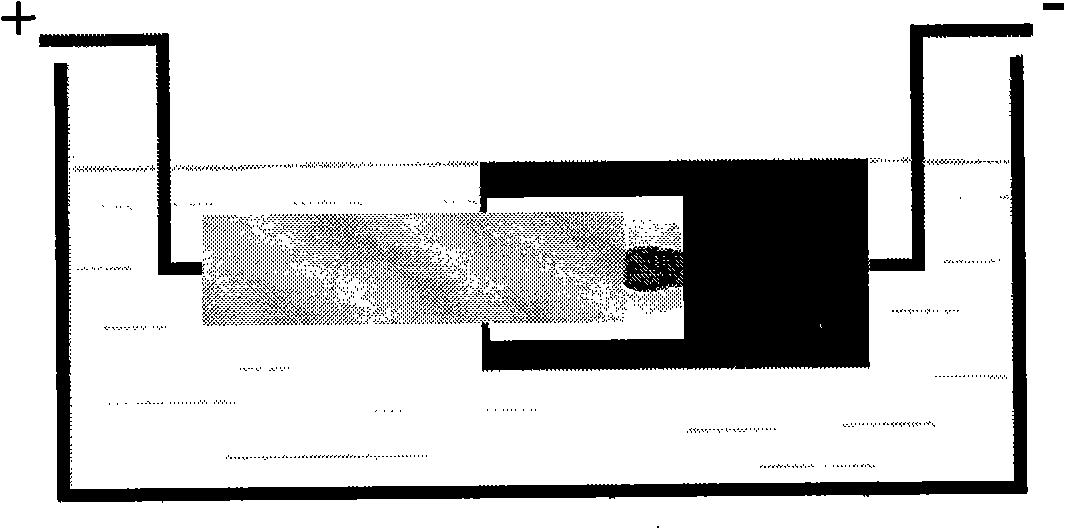

[0022] The preparation device that the present invention adopts sees figure 1 , including DC output power supply, arc discharge device, container, etc. In the arc discharge device, the anode is supplied through the stepping motor, and the stepping motor is controlled by the stepping motor controller, and the control circuit is used to monitor the feeding speed of the cathode and anode , so that the controller can adjust the feed speed in time. A self-feedback system is used to control the speed at which the stepper motor automatically supplies the anode; the self-feedback system includes a control circuit and a stepper motor controller; the cathode and the anode are respectively fixed by a holder, and the detection signal input terminals of the control circuit are respectively connected to the cathode and the anode. For the anode holder, the control signal input end of the stepper motor controller is connected to the output end of the control circuit, and the control signal ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com