Solar heating backheating type efficient methane generation system

A solar heat collection and heat recovery technology, applied in biosynthesis, gas production bioreactors, specific-purpose bioreactors/fermenters, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

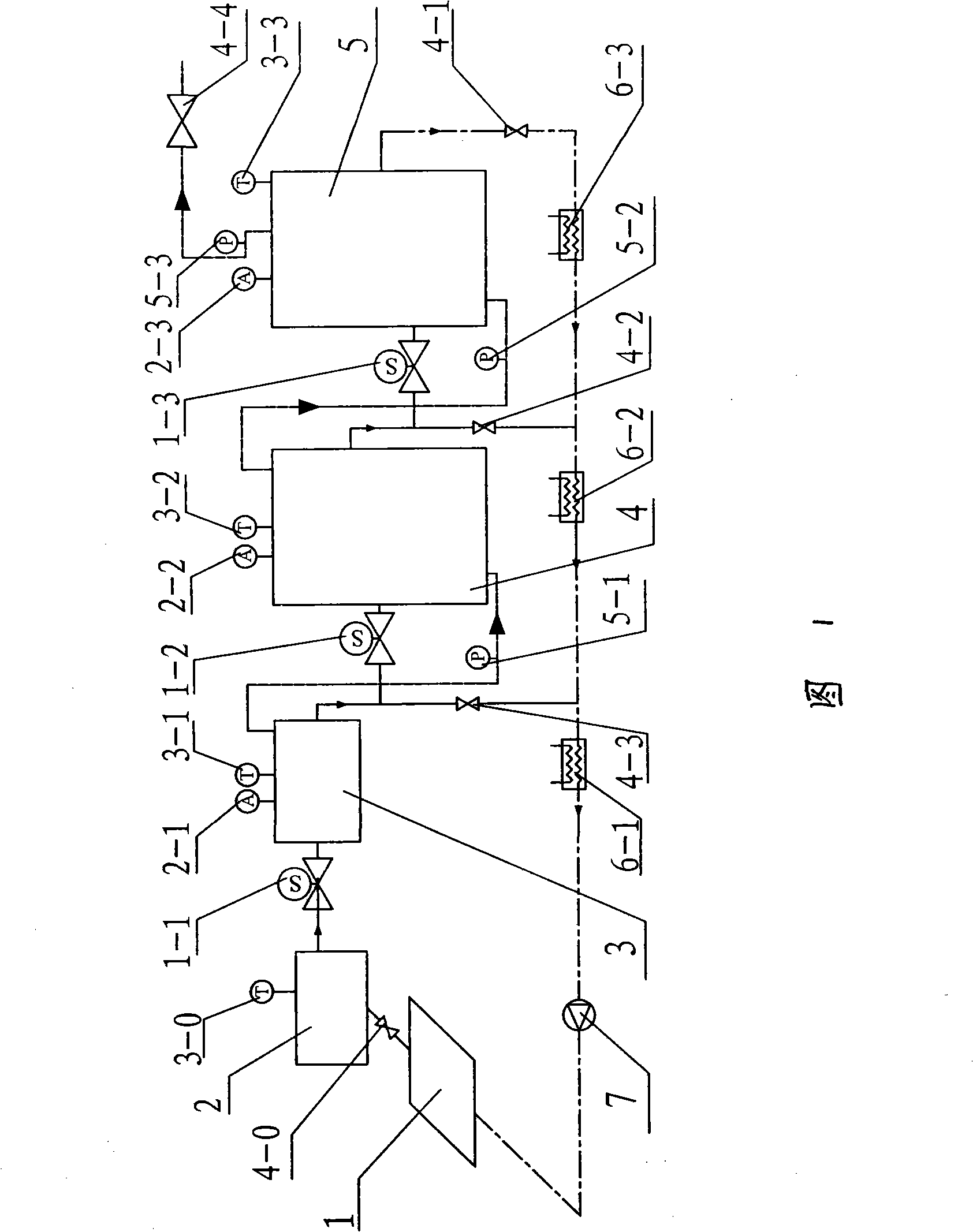

[0017] As shown in Fig. 1, the solar heating recovery type high-efficiency biogas generation system is characterized in that it includes a solar thermal collector 1, and the solar thermal collector 1 is connected with the hot water storage tank 2 through the first valve 4-0 The hot water storage tank 2 is provided with a first temperature sensor 3-0, the hot water storage tank 2 communicates with the high-temperature fermentation device 3 through the first solenoid valve 1-1, and the high-temperature anaerobic fermenter 3 passes through the second solenoid valve 1-2 is connected with the medium temperature anaerobic fermenter 4, the medium temperature anaerobic fermenter 4 is connected with the normal temperature and constant temperature anaerobic fermenter 5 through the third solenoid valve 1-3, and the high temperature anaerobic fermenter 3 is also connected with the medium temperature anaerobic fermentation The device 4 is connected, and the high-temperature anaerobic fermen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com