Drainage water diffluence method for dry red mud disposal and drainage water diffluence structure thereof

A red mud storage yard and red mud technology, applied in the field of red mud dry disposal, can solve problems such as difficult repair, water balance difficulty in alumina plant, red mud attached liquid leakage, etc., to save water resources and production costs, and improve Promotional value and practical value, and the effect of eliminating hidden dangers of water leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

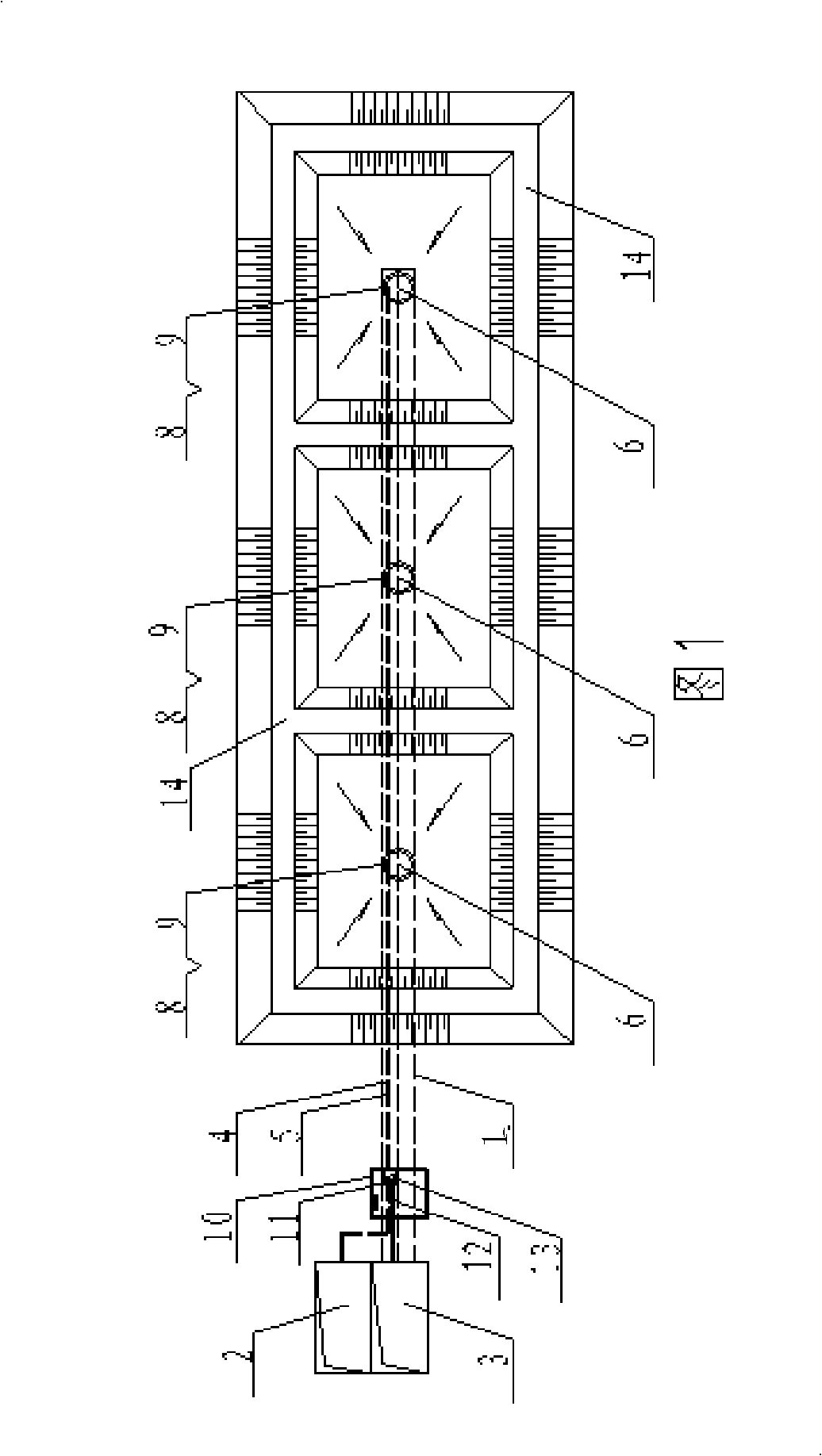

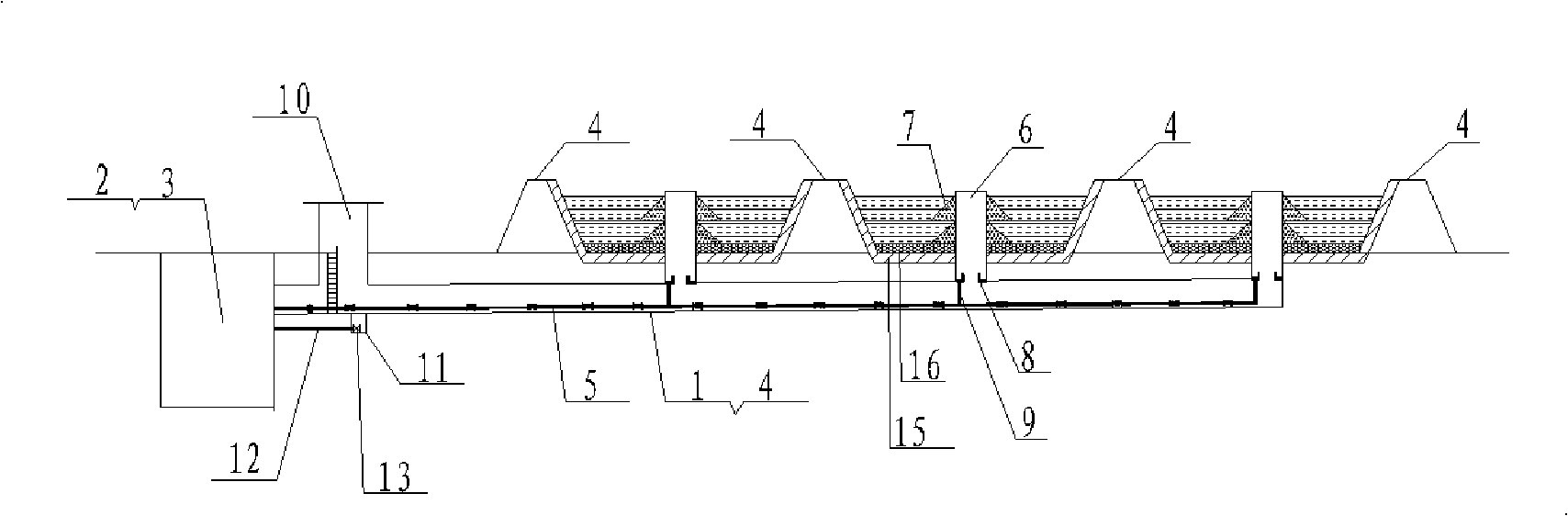

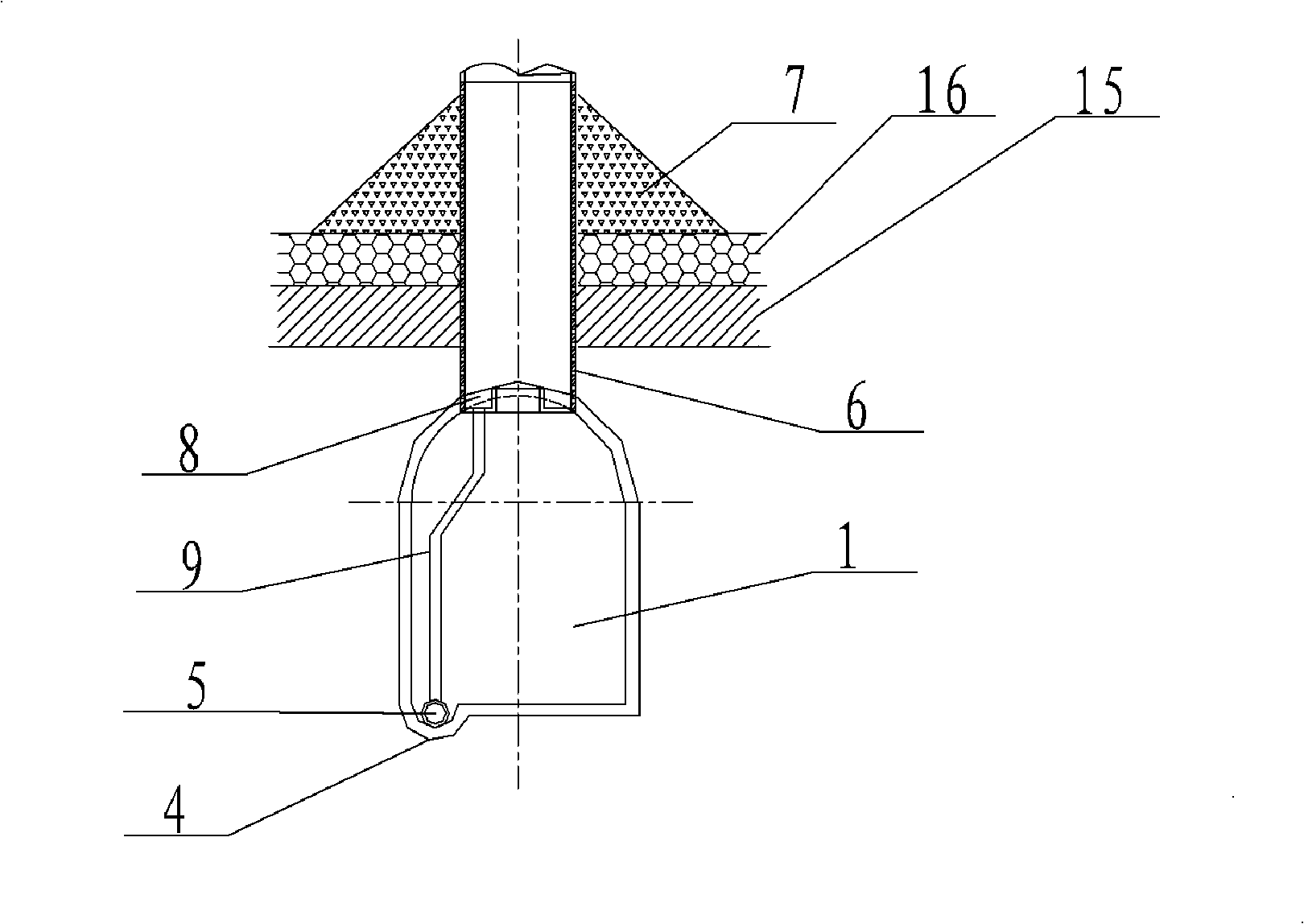

[0022] Embodiment: as shown in Figure 1 figure 2 with image 3 As shown, the drainage and diversion structure of the dry-process red mud stockpile includes the red mud stockpile. At one end of the red mud stockpile, there are two independent red mud attached liquid return pools 2 for storing the red mud attached liquid and storing rainwater. The rainwater return pool 3; the red mud stockpile where the red mud is stacked is divided into several small red mud stacking areas with low middle and high surrounding areas by the initial dam 14, and a water filter pipe 6 is arranged in the center of each small red mud stacking area , the water filter pipe 6 is made of a steel pipe with a diameter of 1-1.5m, and a water seepage hole is opened on the steel pipe. It is connected with the red mud attached liquid return pool 2, and the drainage corridor 1 is built along the route of the return water pipe 5 at the bottom of the red mud storage yard. The drainage corridor 1 is connected with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com