Method and instrument for quantitatively analyzing trace amount acetylene hydrocarbon in carbon four fractions

A technique for quantitative analysis and fractionation, which is applied to instruments, scientific instruments, analytical materials, etc. It can solve the problems of difficulty in distinguishing and accurate qualitative analysis, and achieve the effects of convenient operation, elimination of interference, and good repeatability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

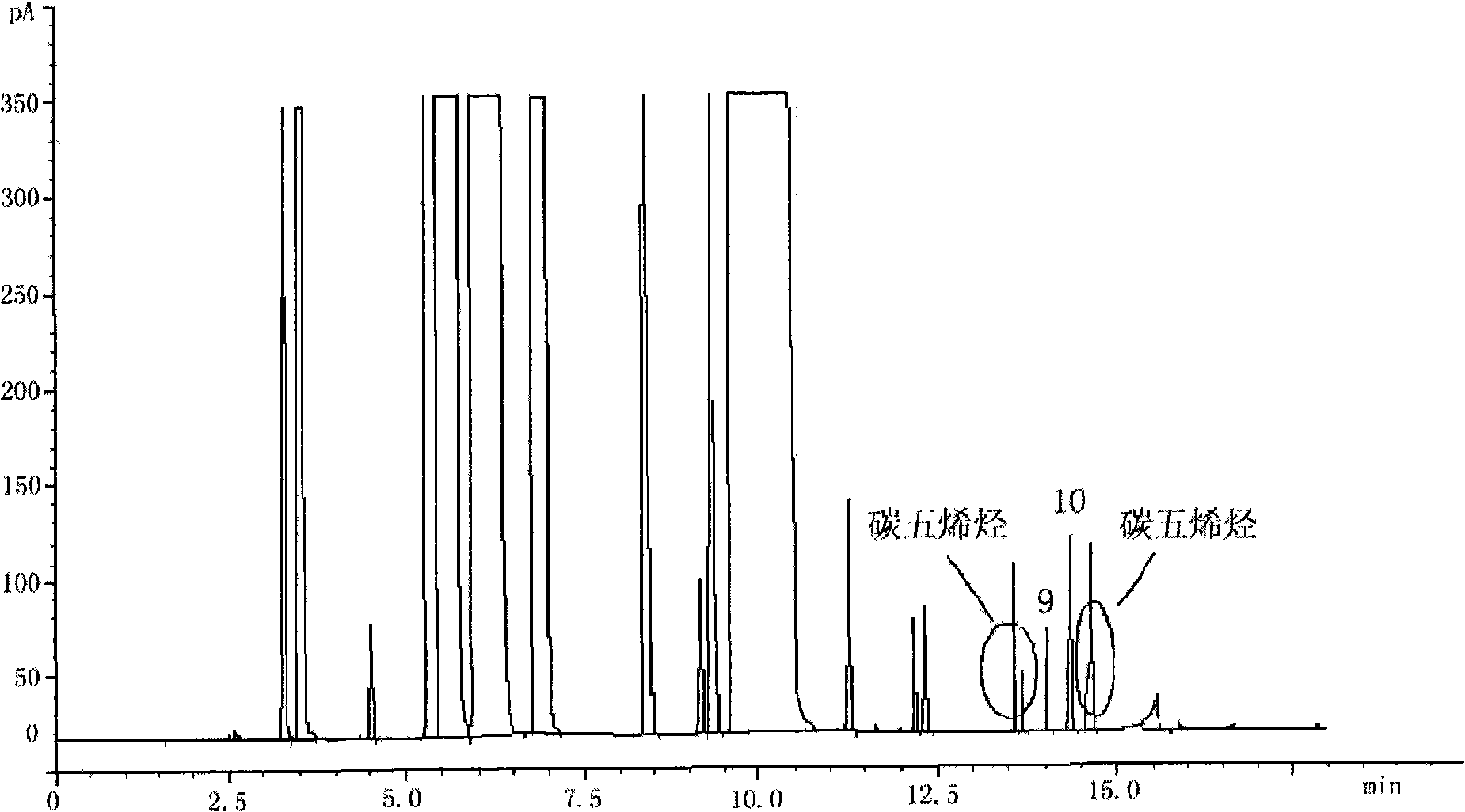

Examples

Embodiment Construction

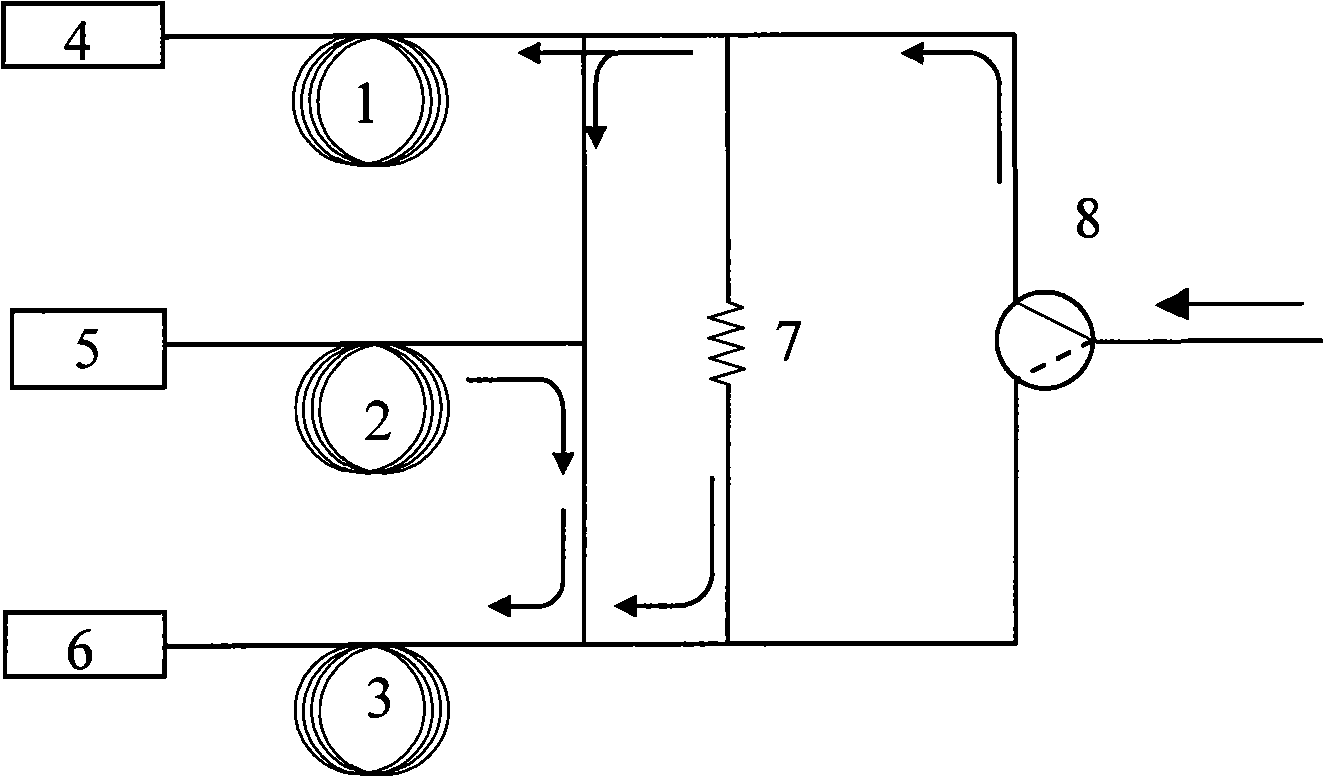

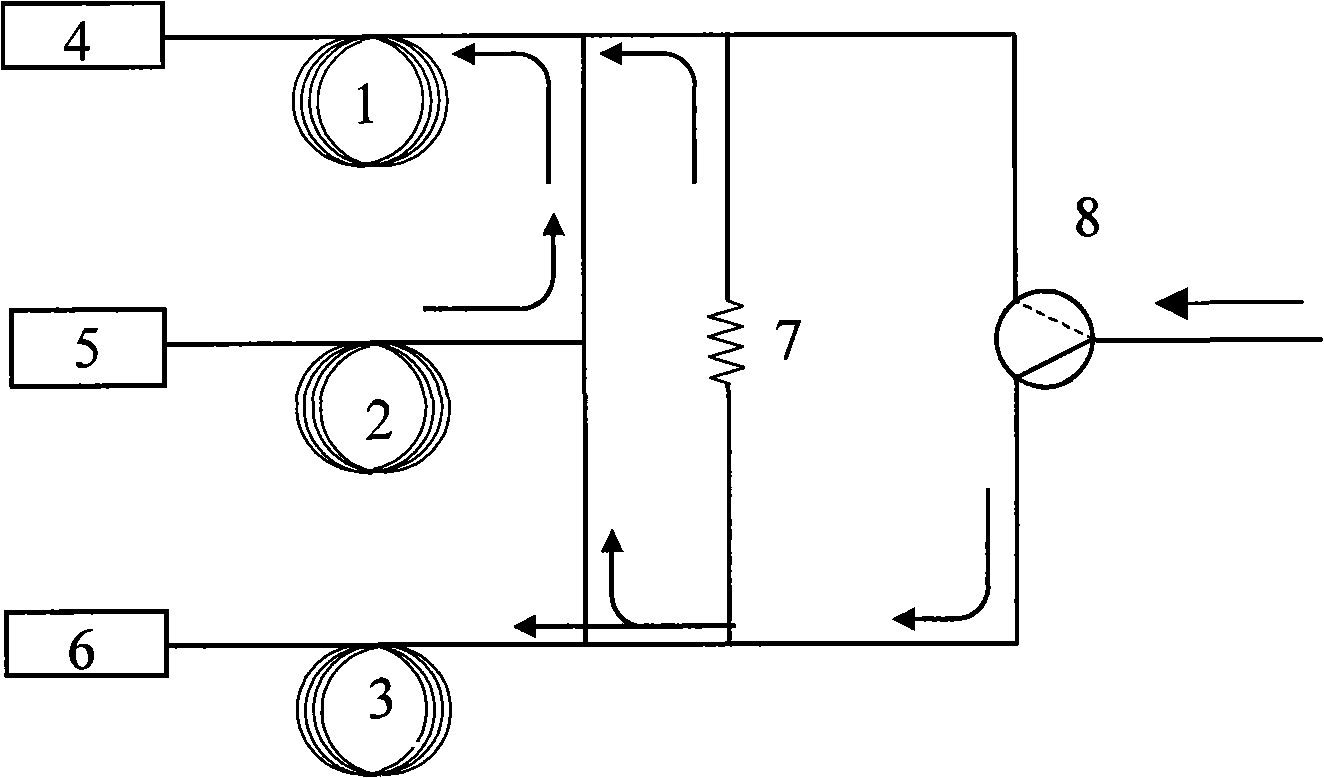

[0025] Refer below figure 1 and 2 The analytical instrument of the present invention is explained in more detail.

[0026] The instrument of the present invention for quantitatively analyzing trace alkynes in cracked C4 cuts comprises a split / splitless inlet 5, a nonpolar chromatographic column 2, a polar chromatographic column 3, a damping column 1, two hydrogen flame detectors 4, 6. Damping tube 7 and electronic steering valve 8; the air resistance of the damping column 1 is equal to the air resistance of the polar chromatographic column 3; the non-polar chromatographic column 2, the polar chromatographic column 3 and the damping column 1 are placed In the column box of the instrument; the split / splitless inlet 5 is connected to the carrier gas source; one end of the non-polar chromatographic column 2 is connected to the split / splitless inlet 5, and the other end is connected to a tee; one end of the damping column 1 is connected to the The hydrogen flame detector 4 is co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com