Method for implementing dual-frequency output laser

A technology of lasers and microchip lasers, which is applied in the field of lasers and can solve problems such as large volume and limited impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: Using optics to process the substrate of the first microchip laser and the substrate of the second microchip laser that meet the required thickness difference. The first microchip laser and the second microchip laser are fabricated from the first substrate and the second substrate with different thicknesses.

Embodiment 2

[0024] Embodiment two: Utilize optical processing to have the substrate of the first microchip laser of considerable thickness and the substrate of the second microchip laser, the substrate of the first microchip laser and the substrate of the second microchip laser are coated with different thickness photoresist films , the film thickness meets the requirement of thickness difference.

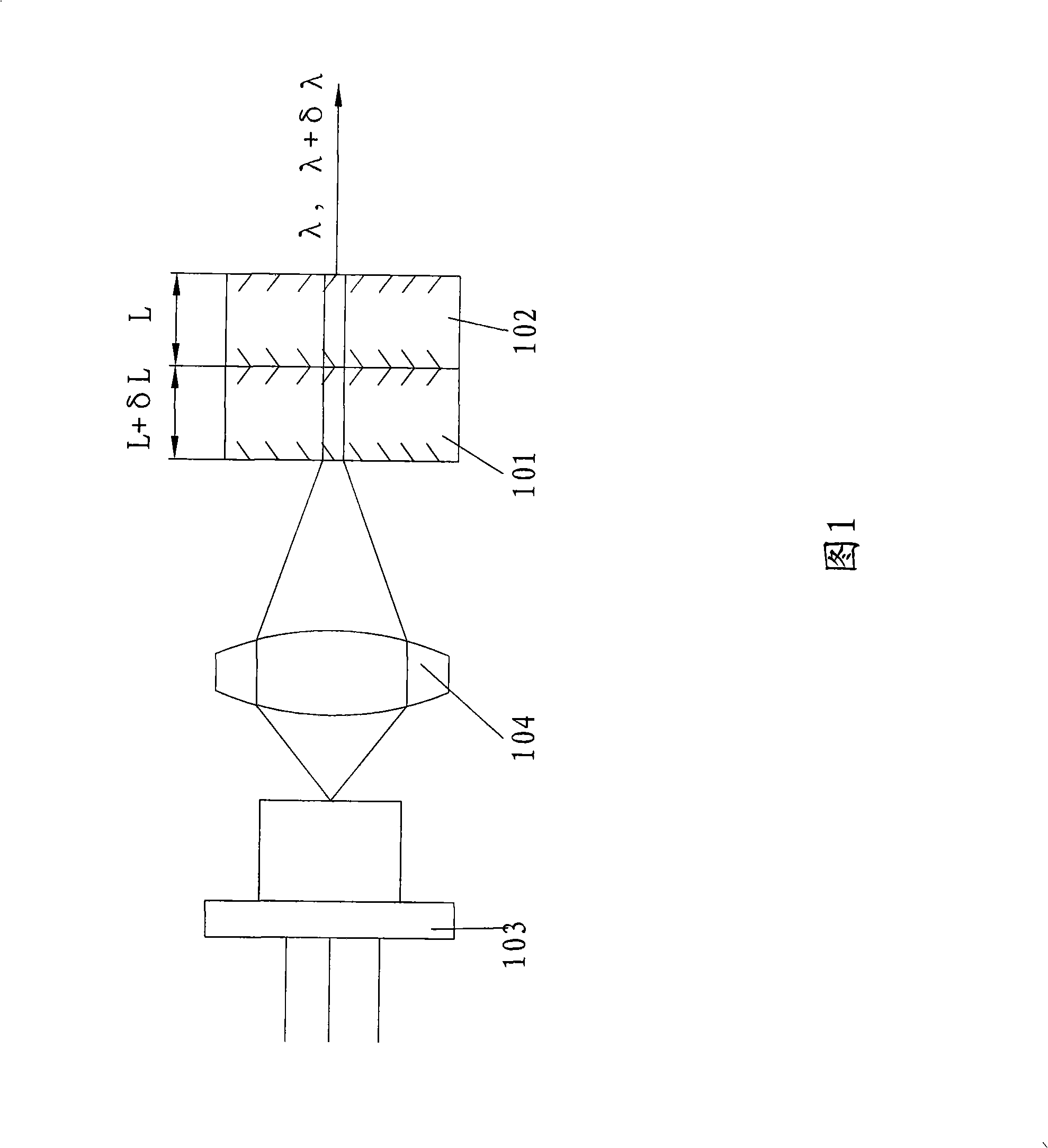

[0025] As shown in Figure 1, 101 and 102 are respectively independent microchip single longitudinal mode lasers, the thickness of the second microchip laser 102 is L, the thickness of the first microchip laser 101 is L+δL, and 103 is the pump of the semiconductor pump laser Pu light source, 104 is an optical coupling system.

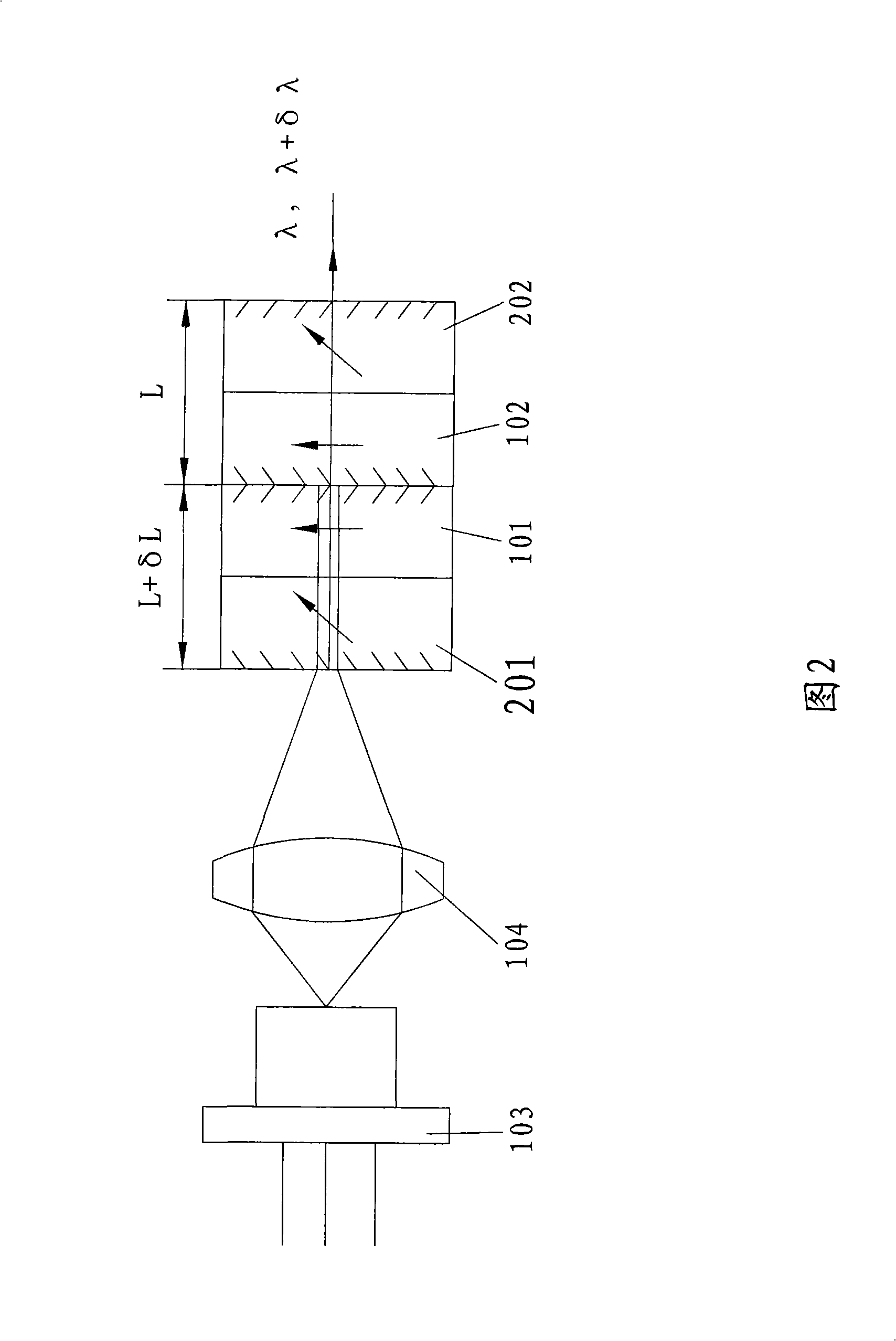

[0026] In Fig. 2, two groups of microchips are composed of laser gain medium and frequency doubling crystal to form an intracavity frequency doubling light output laser. 101 and 102 are laser gain media, and 201 and 202 are frequency doubling crystals.

Embodiment 3

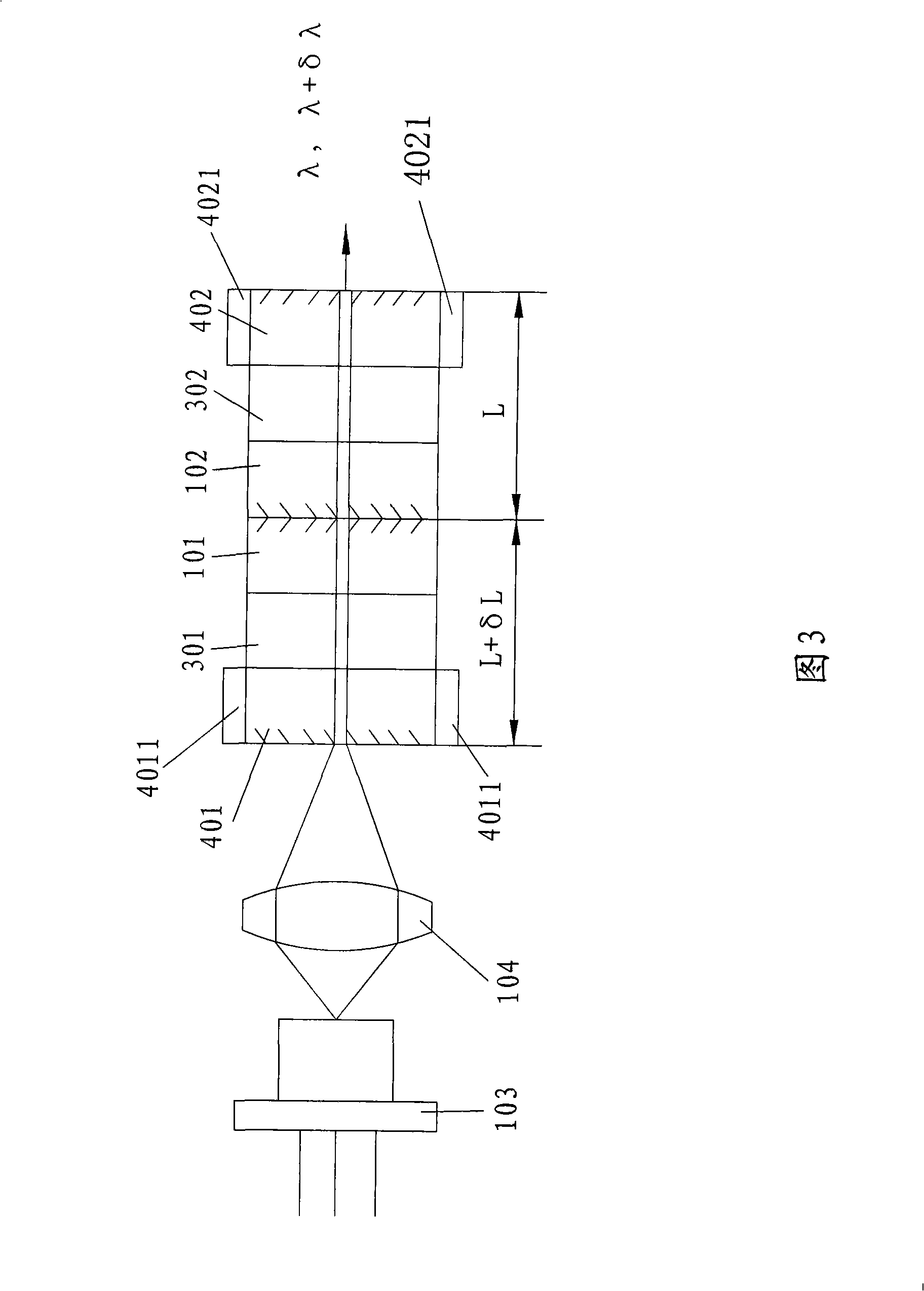

[0027] Embodiment 3: The substrate of the first microchip laser and the second microchip laser substrate of the same tiny wedge angle are optically processed, and the substrate of the first microchip laser is symmetrical to the upside-down second microchip laser substrate place. Such as Figure 4 Among them, 501 and 502 are divided into microchip lasers with a wedge angle of δθ. δθ is so small that the microchip produces laser parallel to the allowable deviation range. L1 and L2 are the thicknesses of the pump light entering 301 and 302 from point C. Obviously, the pump point C is at L1-L2 will change when moving between A and B. This can be changed between the two frequencies by moving the pump point.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com