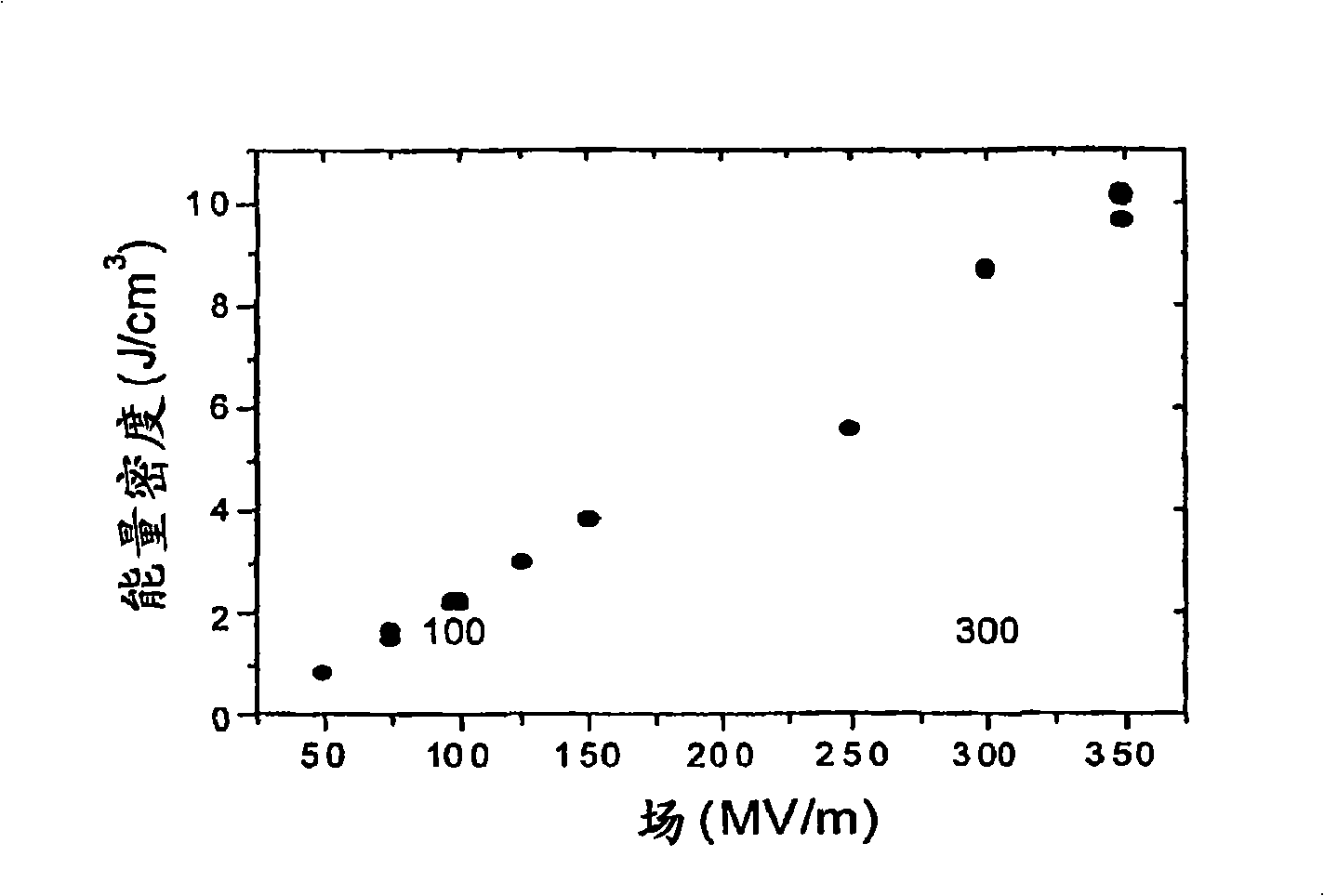

High electric energy density polymer capacitors with fast discharge speed and high efficiency based on unique poly(vinylidene fluoride) copolymers and terpolymers as dielectric materials

A technology of terpolymers and copolymers, applied in the direction of capacitors, fixed capacitors, fixed capacitor dielectrics, etc., can solve problems such as no teaching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

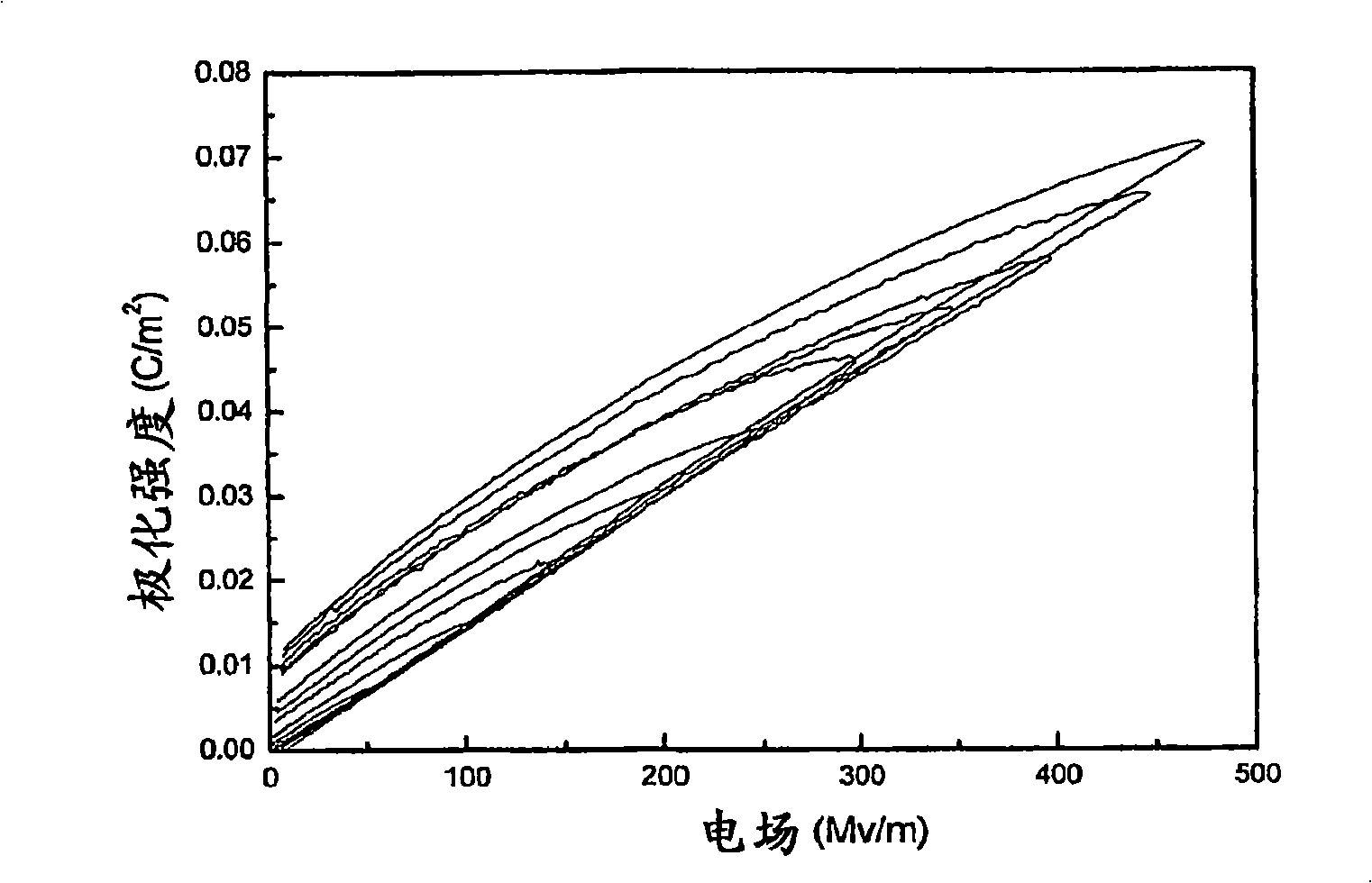

[0032] The present invention provides a device, such as a capacitor, for storing, and / or controlling, and / or manipulating charge and / or electrical energy, with a polymer film as dielectric layer.

[0033] The polymer film can be selected from P(VDF-CTFE), P(VDF-CFE), P(VDF-HFP), P(VDF-CDFE), P(VDF-TrFE-CTFE), P(VDF-TrFE -CFE), P(VDF-TrFE-HFP), P(VDF-TrFE-CDFE), P(VDF-TFE-CTFE), P(VDF-TFE-CFE), P(VDF-TFE-HFP), P Terpolymer or copolymer of (VDF-TFE-CDFE), wherein:

[0034] CTFE: Chlorotrifluoroethylene

[0035] CFE: Chlorofluoroethylene

[0036] HFP: Hexafluoropropylene

[0037] CDFE: Chlorodifluoroethylene

[0038] TrFE: Trifluoroethylene; and

[0039] TFE: Tetrafluoroethylene

[0040] The mol% of CTFE, or CFE, or HFP, or CDFE in the copolymer and terpolymer is within 0 mol% to 10 mol%.

[0041] The mol% of TrFE or TFE in the terpolymer is in the range of 0 mol% to 15 mol%.

[0042] Also provided are polymer blends of PVDF homopolymers and copolymers selected from the g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy density | aaaaa | aaaaa |

| discharge efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com