Method for fixing laminar adhesive protein on Ti-O film surface

A laminin and surface immobilization technology, applied in coating, medical science, prosthesis, etc., can solve the problems of laminin immobilization, and achieve poor blood compatibility, good endothelial cell compatibility, and wide application range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

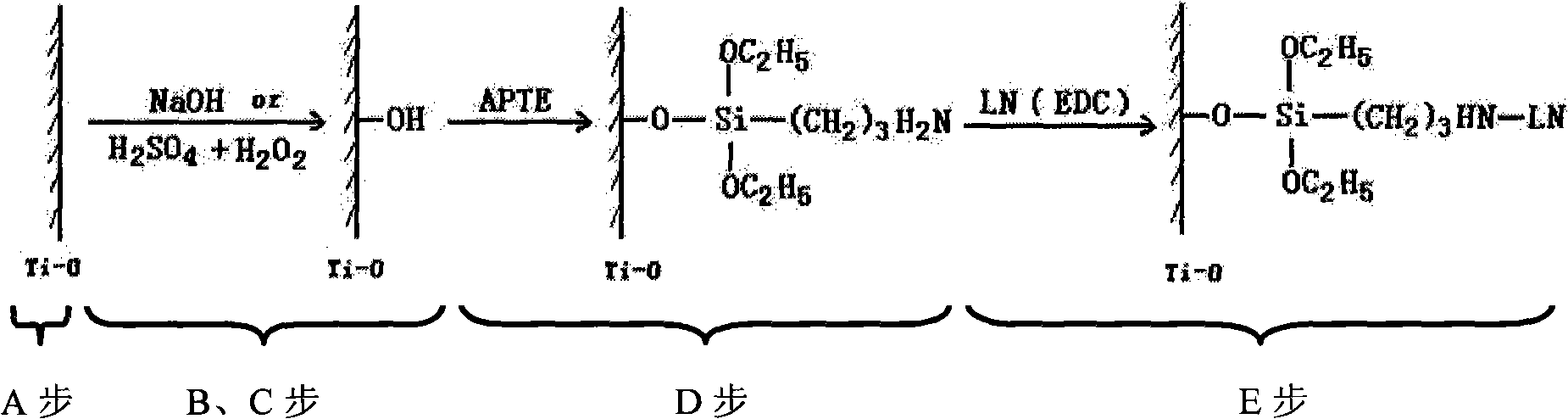

[0023] see figure 1 , the first embodiment of the present invention is a method for immobilizing laminin on the surface of a Ti-O film, the steps of which are:

[0024] A. Cleaning of Ti-O film The anatase crystal Ti-O film was ultrasonically cleaned with acetone, ethanol, and distilled water in sequence for 10 minutes respectively to obtain a clean film surface, and put it into a clean room drying oven for drying;

[0025] B. Activation by Strong Alkali Under oscillating conditions at 50°C, put the clean Ti-O film into NaOH solution with a concentration of 10% WT and soak for 3 hours, then wash it with double distilled water, and then dry it in vacuum;

[0026] C, 98% (WT) H is activated by strong acid 2 SO 4 with 30% (WT) H 2 o 2 Prepare a mixed solution at a volume ratio of 1:1, soak the Ti-O film obtained in step B with the mixed solution for 2 hours at 90° C., then rinse with double-distilled water, and then vacuum-dry;

Embodiment 2

[0030] A method for immobilizing laminin on the surface of a Ti-O film, the steps of which are:

[0031] A. Cleaning of Ti-O film The Ti-O film of anatase and rutile mixed crystal form mainly composed of anatase is ultrasonically cleaned with acetone, ethanol, and distilled water for 8 minutes respectively to obtain a clean film surface. Dry in a clean room drying oven;

[0032] B. Activation by Strong Alkali Under the shaking condition of 80°C, put the clean Ti-O thin film into the NaOH solution with a concentration of 8% WT and soak for 1 hour, then wash it with double distilled water, and then dry it in vacuum;

[0033] C, 98% (WT) H is activated by strong acid 2 SO 4 with 30% (WT) H 2 o 2 Prepare a mixed solution at a volume ratio of 1:3, soak the Ti-O film obtained in step B with the mixed solution for 4 hours at 60° C., then rinse with double distilled water, and then vacuum-dry;

[0034] D. Coupling Prepare an ethanol solution of 3% wt r-aminopropyltriethoxysilane ...

Embodiment 3

[0037] A method for immobilizing laminin on the surface of a Ti-O film, the steps of which are:

[0038] A. Cleaning of Ti-O film The anatase crystal Ti-O film was ultrasonically cleaned with acetone, ethanol, and distilled water for 5 minutes respectively to obtain a clean film surface and dry;

[0039] B. Activation with strong alkali Under the condition of oscillating at 60°C, put the clean Ti-O film into NaOH solution with a concentration of 12% WT and soak it for 5 hours, then rinse it with double distilled water, and then dry it;

[0040] C, 98% (WT) H is activated by strong acid 2 SO 4 with 30% (WT) H2 o 2 Prepare a mixed solution at a volume ratio of 1:0.5, soak the Ti-O thin film obtained in step B with the mixed solution for 1 hour at 95° C., then rinse with double distilled water, and dry;

[0041] D. Coupling Prepare an ethanol solution of 1.5%wt r-aminopropyltriethoxysilane (APTE) as a coupling agent solution, and soak the Ti-O film obtained in step C into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com