Preparation method of polystyrene-divinylbenzene microspheres for bilirubin adsorption

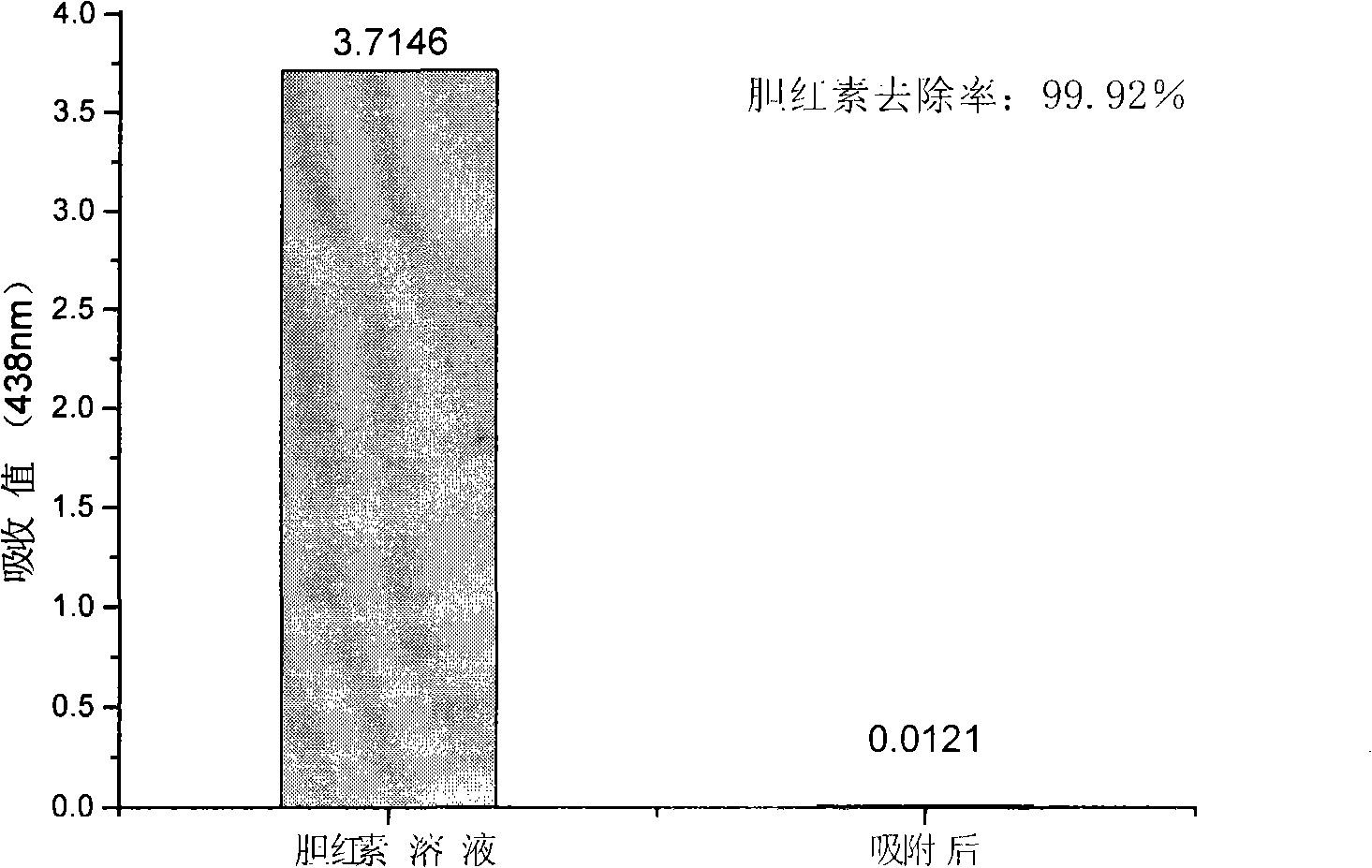

A technology of vinylbenzene microspheres and divinylbenzene, applied in chemical instruments and methods, suction devices, alkali metal oxides/hydroxides, etc., to achieve simple preparation process, efficient adsorption or removal, and good repeatability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Preparation of polystyrene seed polymer microspheres:

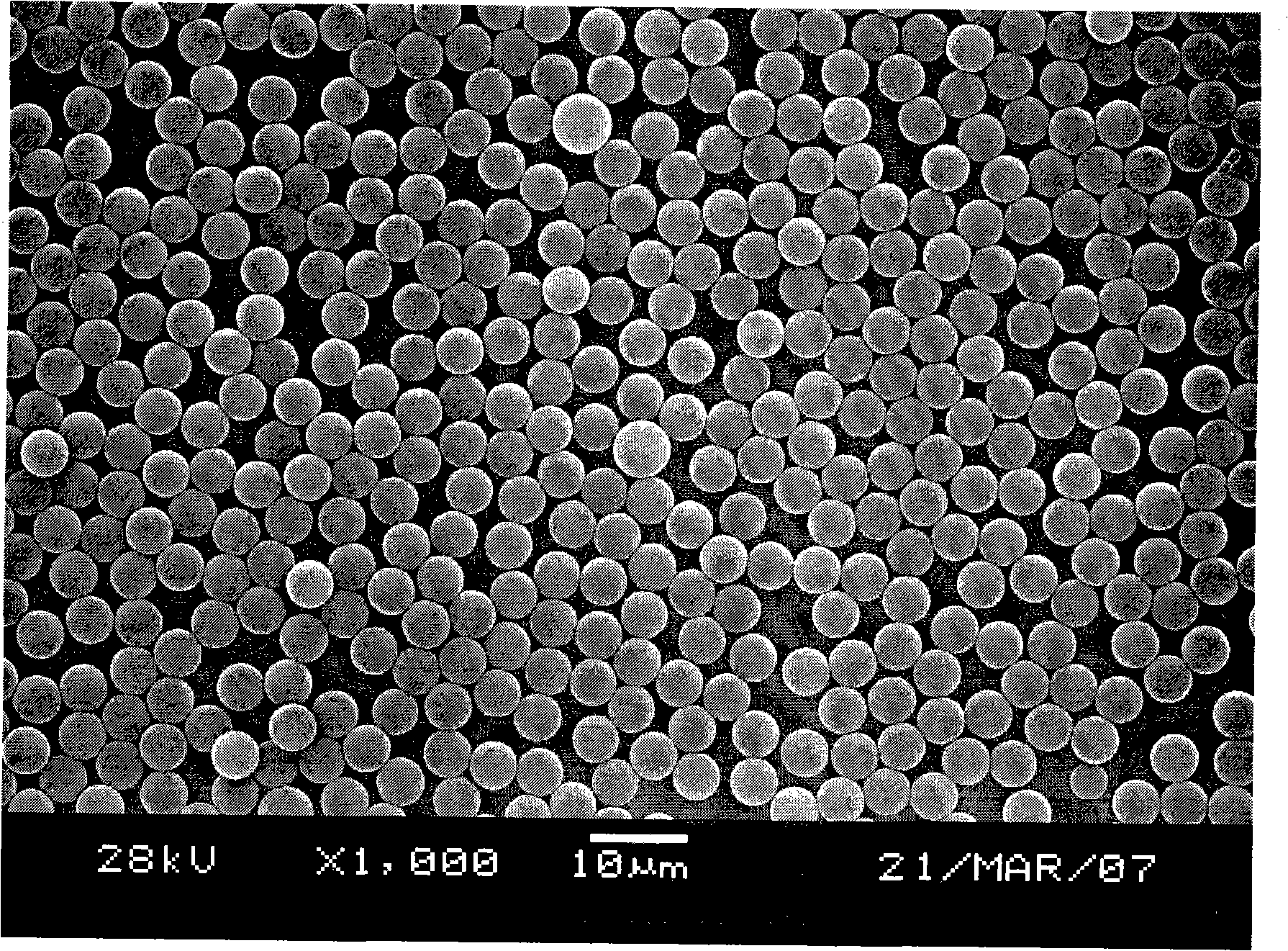

[0046] Dissolve 0.624g of polyvinylpyrrolidone and 290mg of azobisisobutylcyanide in 32mL of 95% (v / v) ethanol aqueous solution, add 8mL of styrene monomer, and dissolve it ultrasonically at a temperature of 0°C-20°C to obtain a transparent solution. The solution was purged with high-purity nitrogen gas for 30 minutes to replace oxygen. React at 70°C for 24 hours under mechanical stirring (stirring speed is 150r.p.m.) to obtain a diameter of about 4.8 μm (such as figure 1 shown) monodisperse polystyrene microspheres. Wash with ethanol several times to remove residual reactants to obtain pure polystyrene microspheres, which are vacuum-dried at 40°C for 24 hours before use.

[0047] Preparation of monodisperse polystyrene-divinylbenzene crosslinked porous polymer microspheres:

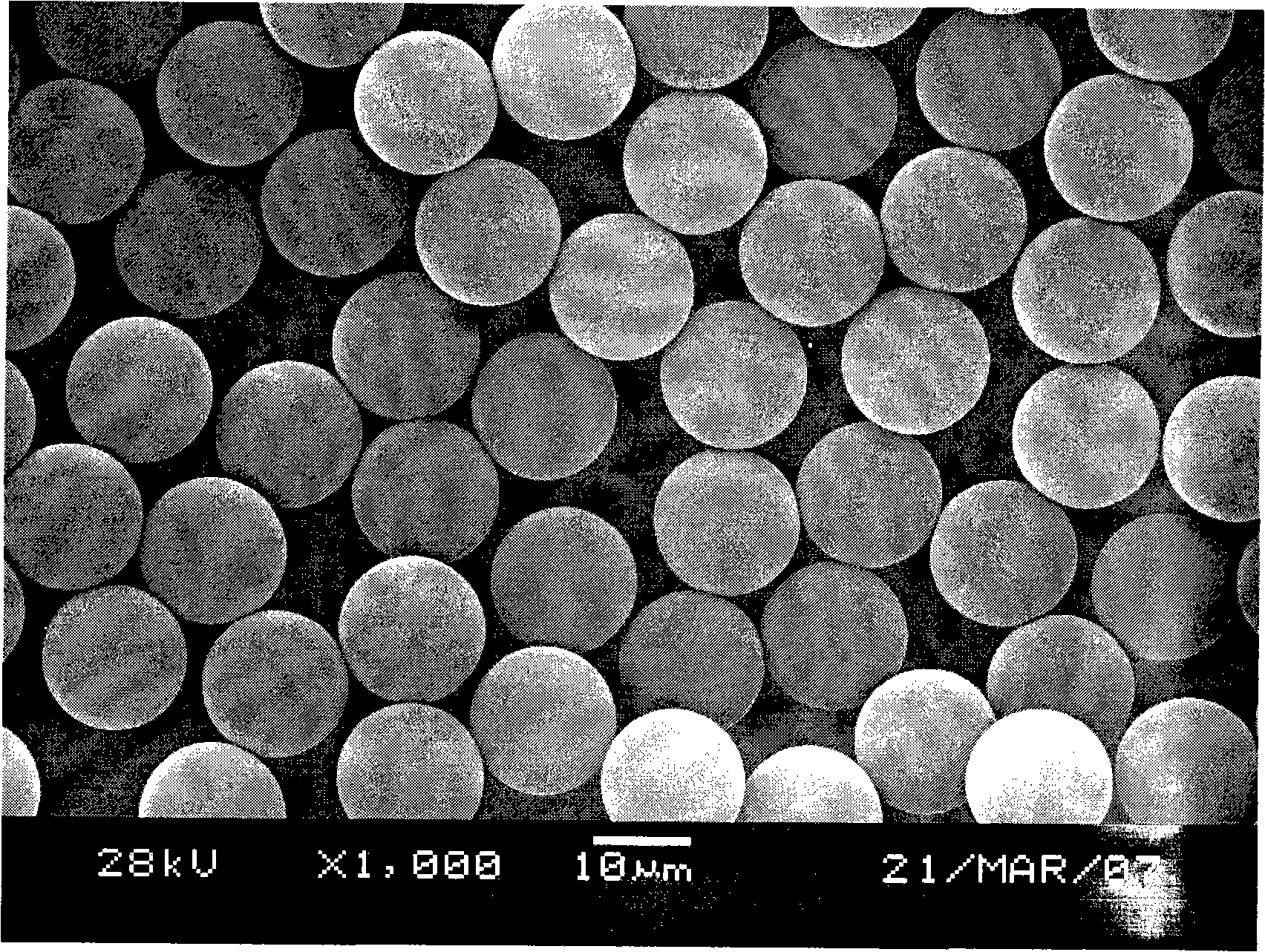

[0048] 0.15g seeds (about 4.8μm in diameter) are evenly dispersed in 5mL containing polyvinyl alcohol (molecular weight: 13000-23000, deg...

Embodiment 2

[0057] Preparation of polystyrene seed polymer microspheres:

[0058] Dissolve 0.624g of polyvinylpyrrolidone and 290mg of azobisisobutylcyanide in 32mL of 95% (v / v) ethanol aqueous solution, add 8mL of styrene monomer, and dissolve it ultrasonically at a temperature of 0°C-20°C to obtain a transparent solution. The solution was purged with high-purity nitrogen gas for 30 minutes to replace oxygen. React at 70°C for 24 hours under mechanical stirring (stirring speed is 150r.p.m.) to obtain a diameter of about 4.8 μm (such as figure 1 shown) monodisperse polystyrene microspheres. Wash with ethanol several times to remove residual reactants to obtain pure polystyrene microspheres, which are vacuum-dried at 40°C for 24 hours before use.

[0059] Preparation of monodisperse polystyrene-divinylbenzene crosslinked porous polymer microspheres:

[0060] 0.1 g of seed microspheres (about 4.8 μm in diameter) were uniformly dispersed in 5 mL of an aqueous solution containing 15% (w / v)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com