Carboxymethyl wood flour with high degree of substitution and preparation method thereof

A technology of carboxymethyl wood flour and high substitution degree, applied in the field of carboxymethyl wood flour, can solve the problems of few processes, low cost and high utilization rate of wood, and achieve the effects of few processes, high utilization rate of wood and low finished product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

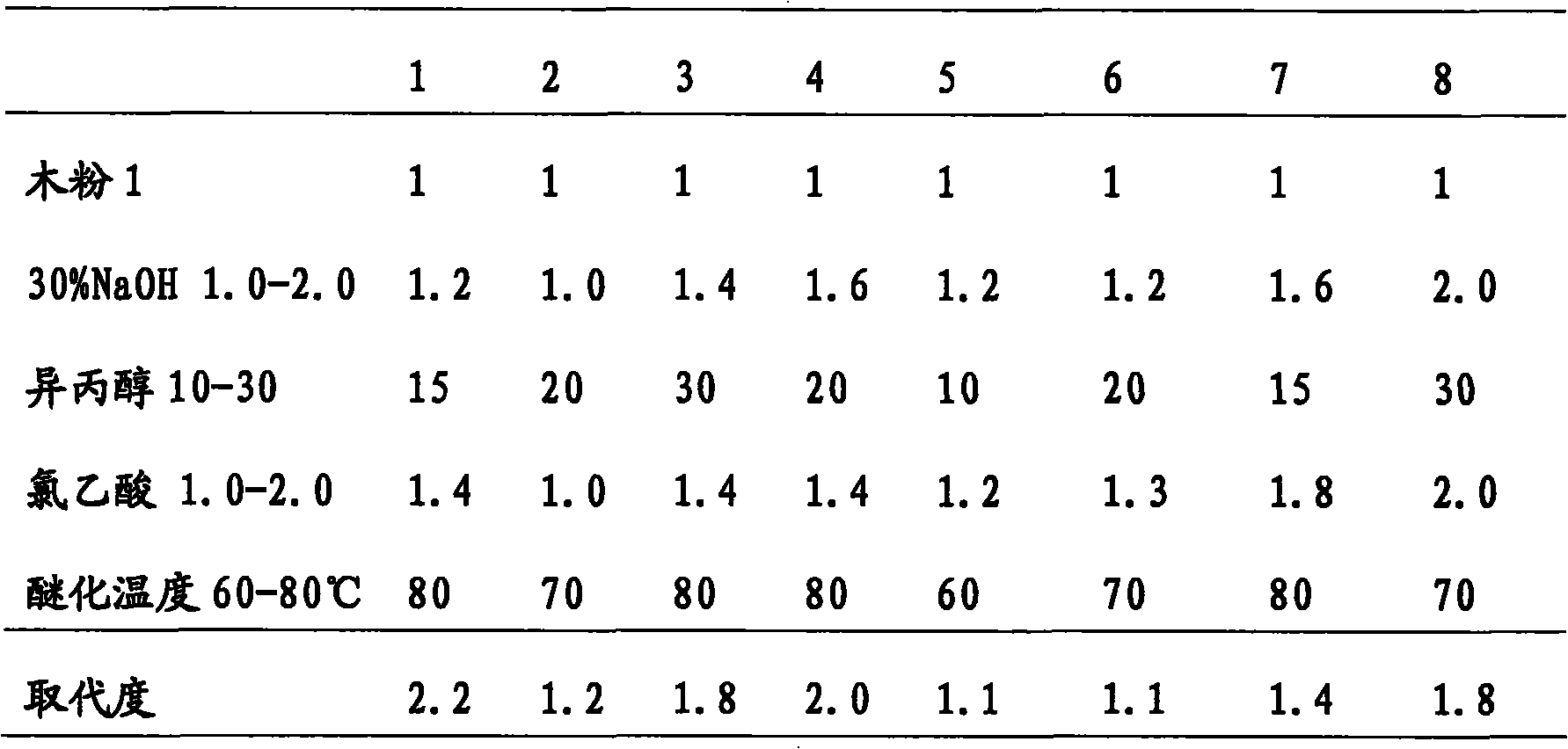

[0018] Embodiment 1 (seeing the corresponding raw materials and parts by weight of Example 1 in the table): add 1 part by weight of 40 object Chinese fir wood powder (hereinafter the same) in the reactor, add 15 parts of isopropanol, 1.2 parts of 30% sodium hydroxide, Stir for 1 hour to generate alkalized wood powder, then add 1.4 parts of chloroacetic acid, control the reaction temperature at 80°C, and stir for 2 hours to obtain a yellow ether compound, which is filtered with 80% ethanol and pure Washing with industrial ethanol, drying, and crushing will produce 100-mesh yellow wood powder-like particles, that is, the carboxymethyl wood powder with high substitution degree, and the substitution degree is 2.2.

[0019] The corresponding raw materials and parts by weight, etherification temperature, and final substitution degree of Examples 2-8 are shown in the table, and the preparation method is the same as that of Example 1. As for the particle size of the raw material wood ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com