Water expansion granule for paddy field and preparation method thereof

A water surface expander and granule technology, which is applied in botany equipment and methods, chemicals for biological control, applications, etc., can solve problems such as high labor intensity, unfriendly environment, difficult use, etc., and reduce labor intensity , avoid secondary pollution, and avoid the effect of cleaning medical equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

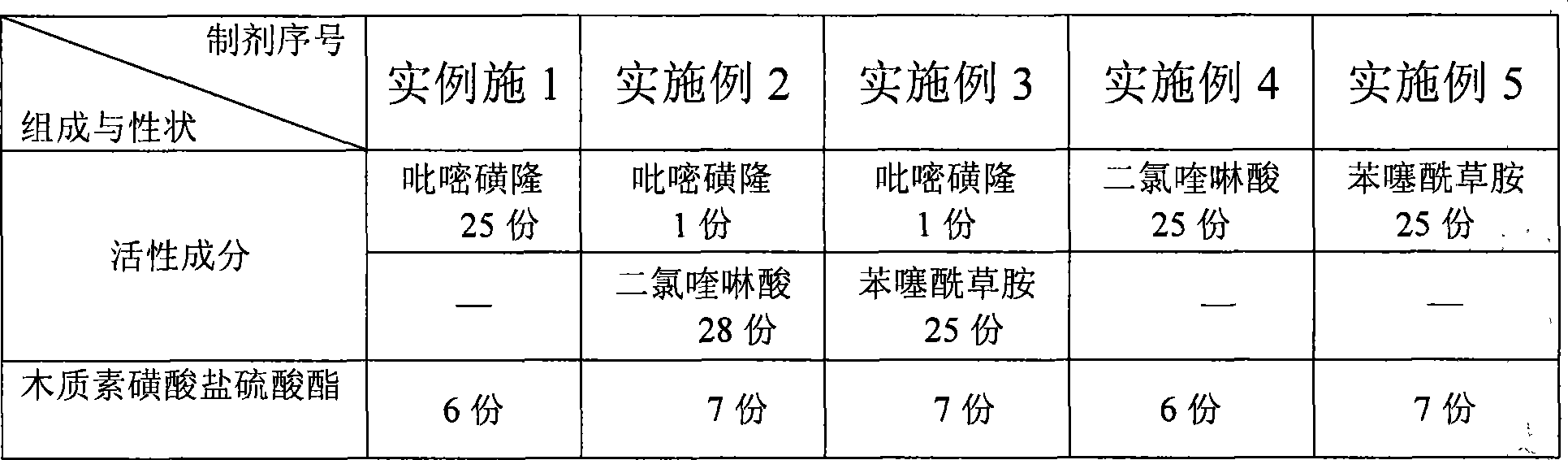

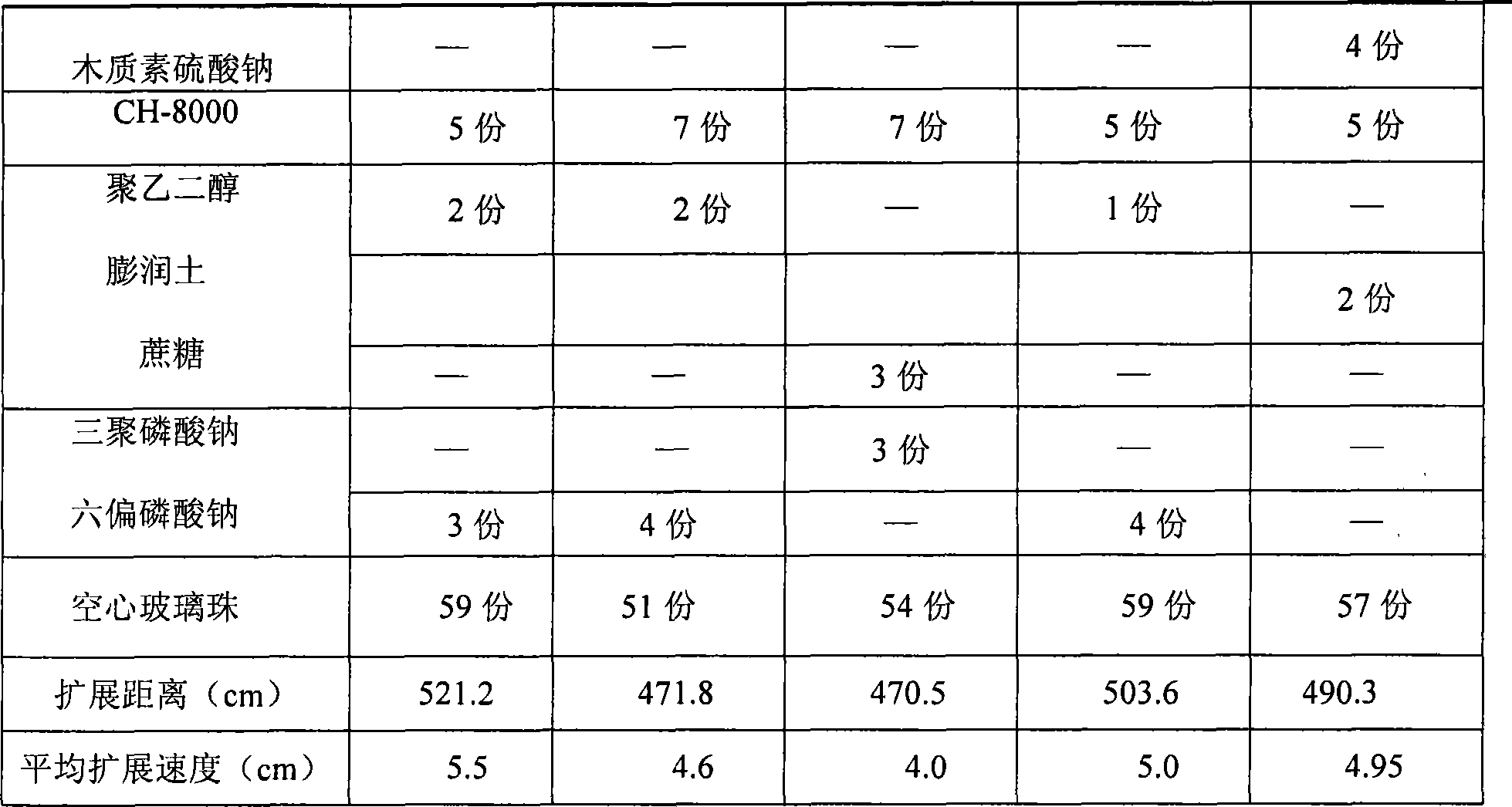

Embodiment 1

[0018] 25 parts of pyrazosulfuron-methyl, 6 parts of lignosulfonate sulfate (purchased from Takemoto), 2 parts of polyethylene glycol and 3 parts of sodium hexametaphosphate (purchased from Jiangsu Yixing Auxiliary Factory) were mixed in a double-helix mixer Mix in 30 minutes, drop into the kneader together with 59 parts of hollow glass beads after being pulverized by a jet mill, then drop into 5 parts of fatty acid ethylene glycol ester (CH-8000, purchased from Takemoto company) and 20 parts of water, knead for 15 After -30 minutes, use an extrusion granulator to granulate, dry in a hot air circulation drying oven (temperature ≤ 60°C), sieve and pack after sampling and testing pass.

Embodiment 2

[0020] 1 part of pyrazosulfuron-methyl, 28 parts of quinclorac, 4 parts of sodium hexametaphosphate (purchased from Jiangsu Yixing Auxiliary Factory), 7 parts of lignosulfonate sulfate (purchased from Takemoto Company) and 2 parts of poly Ethylene glycol was mixed with a double-screw mixer for 30 minutes, pulverized by a jet mill and put into a kneader together with 51 parts of hollow glass beads, and then dropped into 7 parts of fatty acid ethylene glycol esters (CH-8000, purchased from Takemoto company) and 19 parts of water, kneaded for 30 minutes, granulated with an extrusion granulator, dried in a fluidized bed (air inlet temperature ≤ 90° C.), sieved and packaged after passing the test.

Embodiment 3

[0022] Mix 1 part of pyrazosulfuron-methyl, 25 parts of mefenamide, 3 parts of sodium tripolyphosphate (purchased from Jiangsu Yixing Auxiliary Factory), 7 parts of lignosulfonate sulfate and 3 parts of sucrose in a double-helix mixer Mix for 30 minutes, drop into the kneader together with 54 parts of hollow glass beads after being pulverized by a jet mill, then drop into 7 parts of fatty acid ethylene glycol esters (CH-8000, purchased from Takemoto company) and 19 parts of water, and knead for 30 minutes Finally, granulate with an extrusion granulator, dry in a fluidized bed (air inlet temperature ≤ 90°C), sieve and pack after passing the test.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com