3-amino propanesulfonic acid preparation method

A technology of aminopropanesulfonic acid and sodium sulfate, which is applied in the intermediate of calcium acamprosate and the new preparation field of 3-aminopropanesulfonic acid, can solve the problems of high raw material price and high production cost, and achieve low production cost, The effect of low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

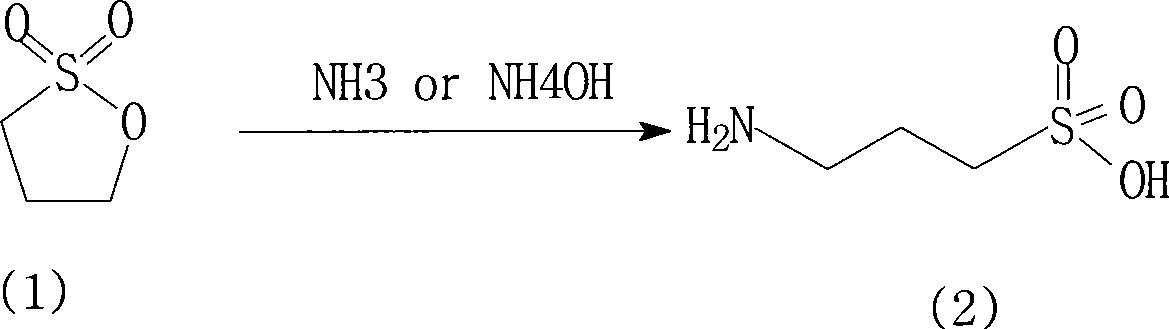

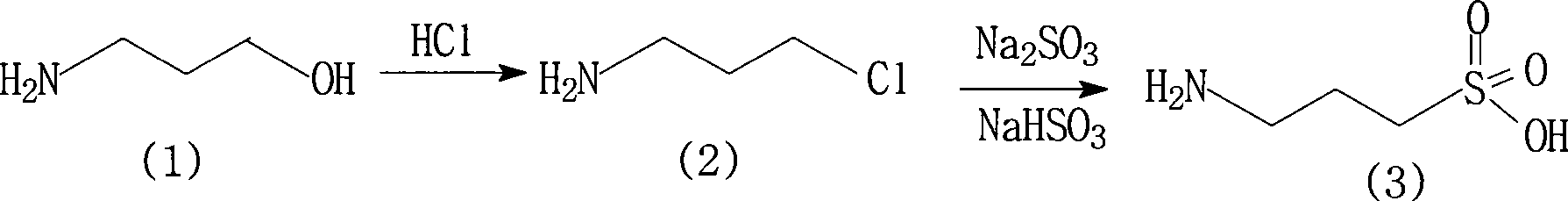

Method used

Image

Examples

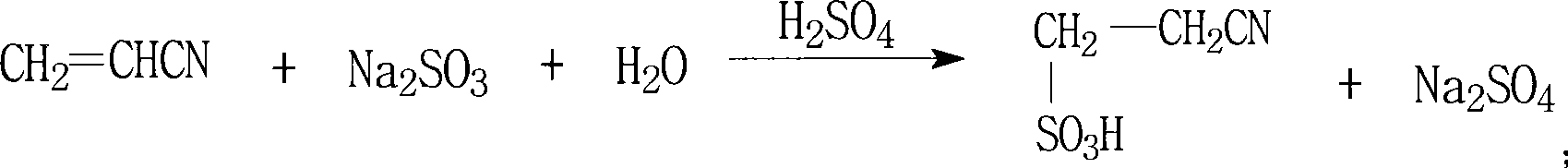

Embodiment 1

[0023] Example 1. Dissolve 1 mol of sodium sulfite in 0.3 L of water, add 1 mol of acrylonitrile and 0.5 mol of 98% concentrated sulfuric acid dropwise at room temperature at the same time, and dropwise add in about 1 hour. After the reaction is complete, set the pH value of the system to 7, and distill to dryness under negative pressure. Obtain 3-sulfopropionitrile and sodium sulfate solids; cool to 30°C, add 0.8L of absolute ethanol to dissolve the solids, heat up to 78°C and reflux for 2 hours, filter while hot to remove sodium sulfate; place the filtrate in a hydrogenation reactor, Add ammonia ethanol solution, set the pH value of the system to 10, use Raney nickel as the catalyst, the addition amount is 2% of the total amount of the reaction system, hydrogenation reaction, keep the reaction temperature at 60°C, the pressure at 2.0MPa, and the time for 6h, Until no hydrogen is absorbed; after the reaction, ethanol is recovered, and the material is cooled and precipitated t...

Embodiment 2-3

[0026]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com