Cefpirome sulfate preparation technology

A technology of cefpirome sulfate and preparation process, applied in the field of cefpirome sulfate, can solve the problems of unsatisfactory yield, complicated operation and high cost, and achieve the effects of high yield, high purity and good crystal form

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

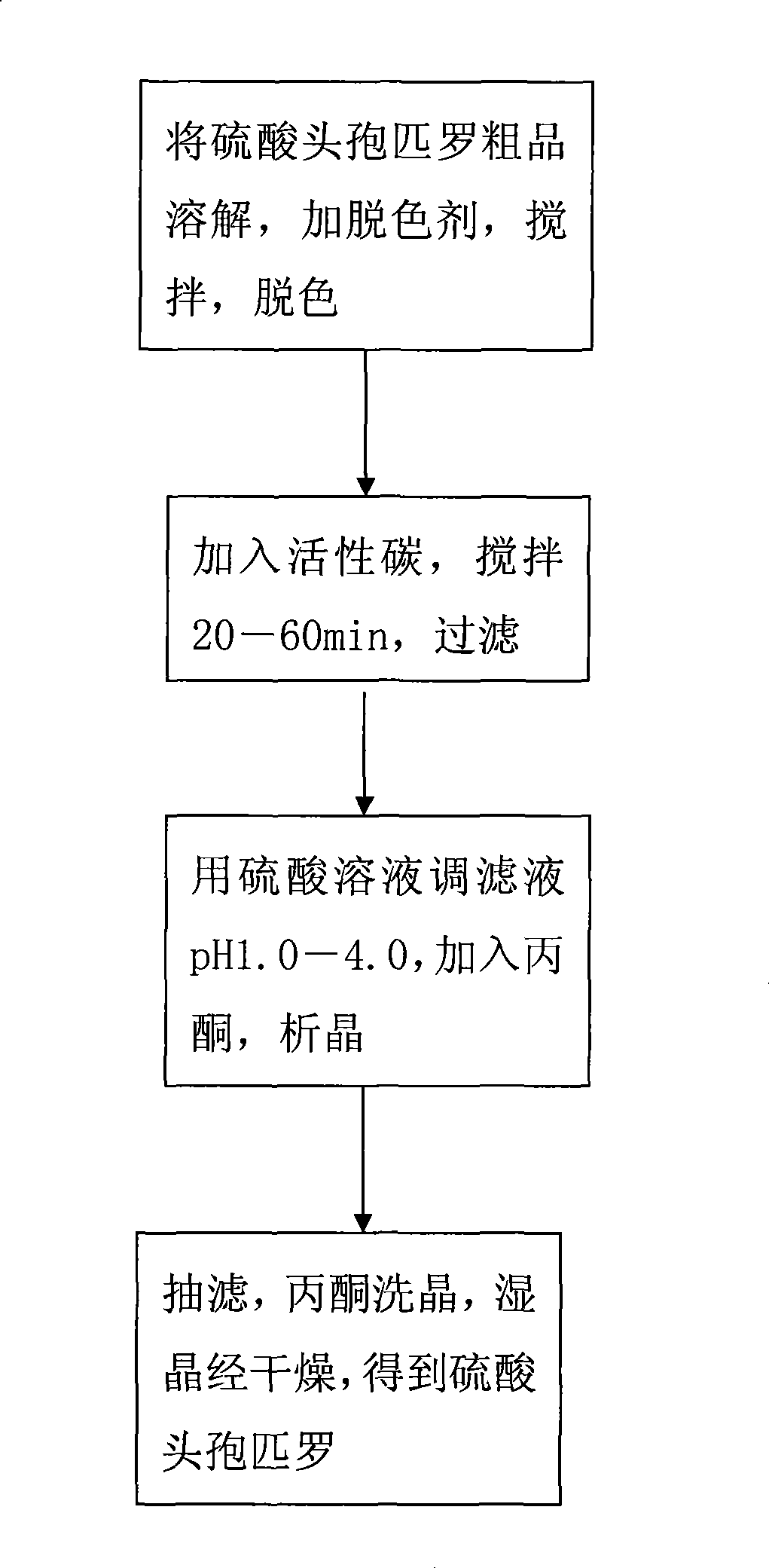

[0029] Such as figure 1 Shown, a kind of cefpirome sulfate refining technique, carries out according to the following steps:

[0030] 1. Add 20g of cefpirome sulfate coarse powder, 100ml of water and 10ml of methanol into a 250ml three-neck bottle, then add dropwise 3mol / l sodium carbonate solution, stir, and adjust the pH to 3.0-6.0 to dissolve the solid in the bottle.

[0031] 2. Add activated carbon, stir for 30 minutes, and filter. Can continue to add activated carbon to the filtrate as required, stir for 30min, filter, and so many times.

[0032] 3. Use 2mol / l sulfuric acid solution to adjust the pH of the filtrate to 1.0-4.0, add acetone, and crystallize.

[0033] 4. Suction filtration, washing the crystals with acetone, and drying the wet crystals to obtain cefpirome sulfate.

[0034] The molar yield of cefpirome sulfate prepared in this embodiment is 94.3%, the crystal is slightly yellow, and the HPLC detection content is 95.2%, and the solution color is greater tha...

Embodiment 1

[0037] Such as figure 1 Shown, a kind of cefpirome sulfate refining technique, carries out according to the following steps:

[0038] 1. Add 20 g of cefpirome sulfate coarse powder of the same batch as Experimental Example 1, 100 ml of water and 10 ml of methanol in a 250 ml three-necked bottle, then add dropwise 3mol / l sodium carbonate solution, stir, and adjust the pH to 3.0-6.0, Dissolve the solid in the bottle, fill the bottle with nitrogen for protection, then add 0.2 g of sodium metabisulfite, stir, and decolorize.

[0039] 2. Add activated carbon, stir for 30 minutes, and filter.

[0040] 3. Use 2mol / l sulfuric acid solution to adjust the pH of the filtrate to 1.0-4.0, add acetone, and crystallize.

[0041] 4. Suction filtration, washing the crystals with acetone, and drying the wet crystals to obtain cefpirome sulfate.

[0042] The molar yield of cefpirome sulfate prepared in this embodiment is 93.9%, the crystal is white, the HPLC detection content is 97.7%, and th...

Embodiment 2

[0045]In this embodiment, the dosages are 20 g cefpirome sulfate coarse powder, 22 ml ethanol, 0.16 g sodium metabisulfite, and 3 mol / l sodium hydroxide solution.

[0046] Others are the same as embodiment 1.

[0047] The molar yield of cefpirome sulfate prepared in this embodiment is 94.5%, the crystal is white, the HPLC detection content is 94.3%, and the solution color is smaller than the yellow No. 1 standard colorimetric solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com