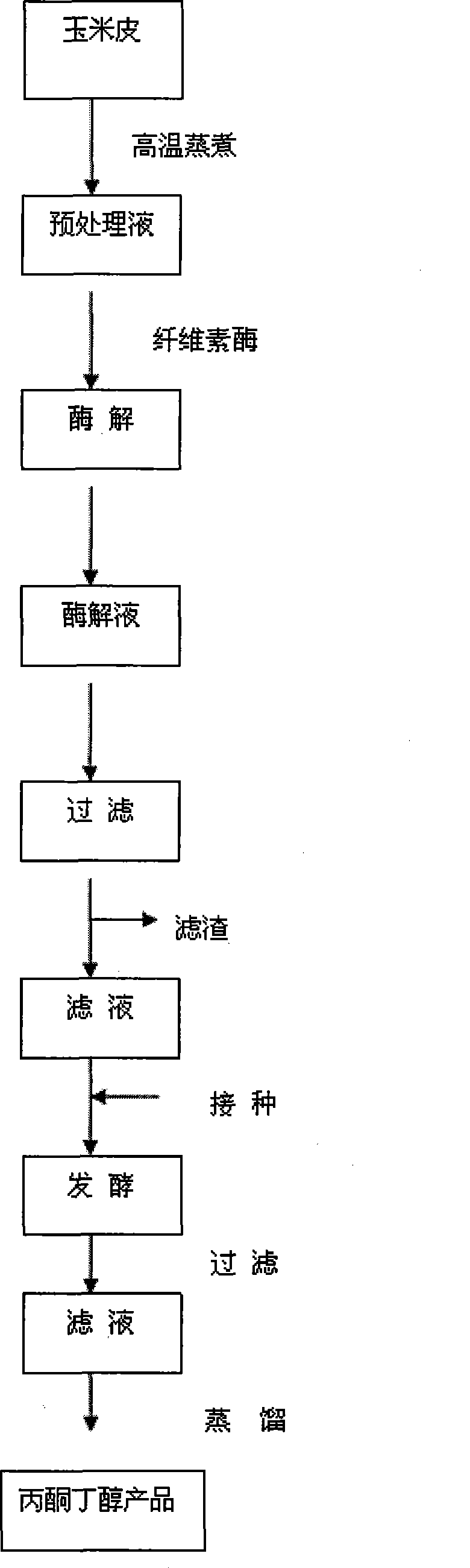

Method for producing acetone-butanol using fermentation of corn bran raw material

A technology of acetone butanol and corn husks, applied in microorganism-based methods, biochemical equipment and methods, fermentation and other directions, can solve the problems of reducing the utilization rate of raw materials, insufficient utilization of corn husk starch cellulose, etc. Effects of sustainable utilization, improved competitiveness, and improved utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

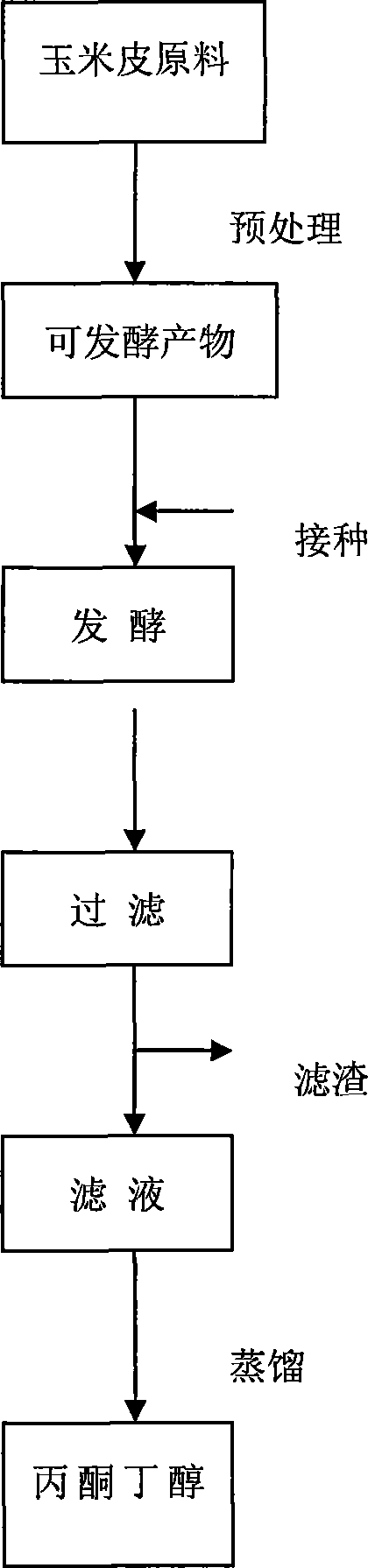

[0028] Embodiment 1: Direct cooking and fermentation of corn bran raw material ABE (bacteria are purchased from Institute of Plant Health, Chinese Academy of Sciences, the same below)

[0029] Weigh 37.5 grams of corn husks and add 150ml of water, adjust the pH to 7.0, a total of three groups of parallel samples, cook at 121°C for 1 hour, cool to about 37-40°C, and ferment with ABE strains, the fermentation temperature is 37°C, and the fermentation cycle is 48 hours .

[0030] After the fermentation was finished, the fermented liquid was centrifuged at 12,000 rpm for 5 minutes, and the contents of acetone, butanol and ethanol were determined by gas chromatography after taking out. The solvent determination results are shown in Table 1.

[0031] Table 1 ABE results of corn bran raw material fermentation

[0032]

[0033] It can be seen from the results in the table that when the residual starch in the corn husk is relatively high, the residual starch can be used for ABE fer...

Embodiment 2

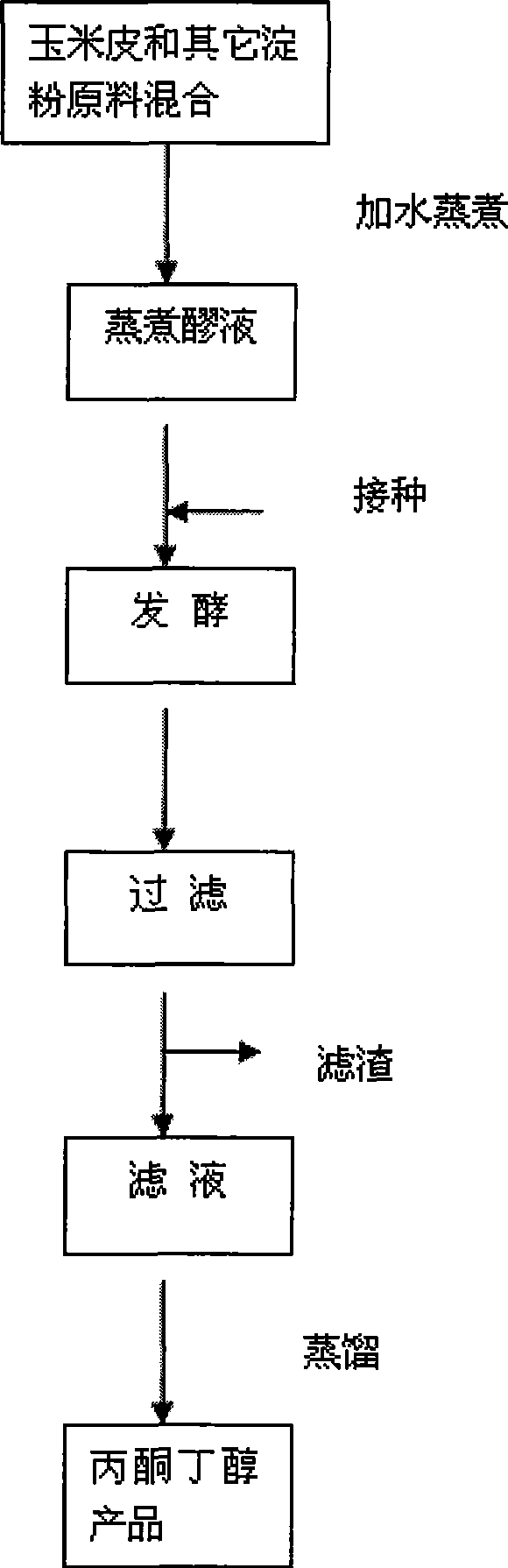

[0034] Embodiment 2: mixed fermentation of corn husk and cassava

[0035] According to the solid-liquid ratio of 1:5, 1:7, 1:9, weigh the corn husks and mix them with water, add 3%, 4%, and 5% cassava flour to the mixture of the three ratios, and each group has 3 parallel samples, 121 Cook at ℃ for 1 hour, cool to about 37-40℃, then ferment with ABE strain, the fermentation temperature is 37℃, and the fermentation cycle is 48 hours.

[0036] After the fermentation was finished, the fermented liquid was centrifuged at 12,000 rpm for 5 minutes, and the contents of acetone, butanol and ethanol were measured by gas chromatography after taking out. The solvent measurement results are shown in Table 2.

[0037] Table 2 Fermentation results of corn husk and cassava mixture

[0038]

[0039] It can be seen from the results in the table that when the residual starch content in the corn husk is low, some cassava flour can be added to it for fermentation, and the fermentation result ...

Embodiment 3

[0040] Embodiment 3: the mixed fermentation of corn husk and sweet potato powder

[0041] According to the solid-liquid ratio of 1:5, 1:7, 1:9, weigh the corn husks and mix them with water, add 3%, 4%, and 5% sweet potato flour to the mixture of the three ratios, and each group has 3 parallel samples, 121 Cook at ℃ for 1 hour, cool to about 37-40℃, then ferment with ABE strain, the fermentation temperature is 37℃, and the fermentation cycle is 48 hours.

[0042] After the fermentation was finished, the fermented liquid was centrifuged at 12,000 rpm for 5 minutes, and the contents of acetone, butanol and ethanol were measured by gas chromatography after taking out, and the results of the solvent determination were shown in Table 3.

[0043] Table 3 Mixed fermentation results of corn husk and sweet potato flour

[0044]

[0045] It can be seen from the results in the table that when the residual starch content in the corn husk is low, adding sweet potato powder to it for ferme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com