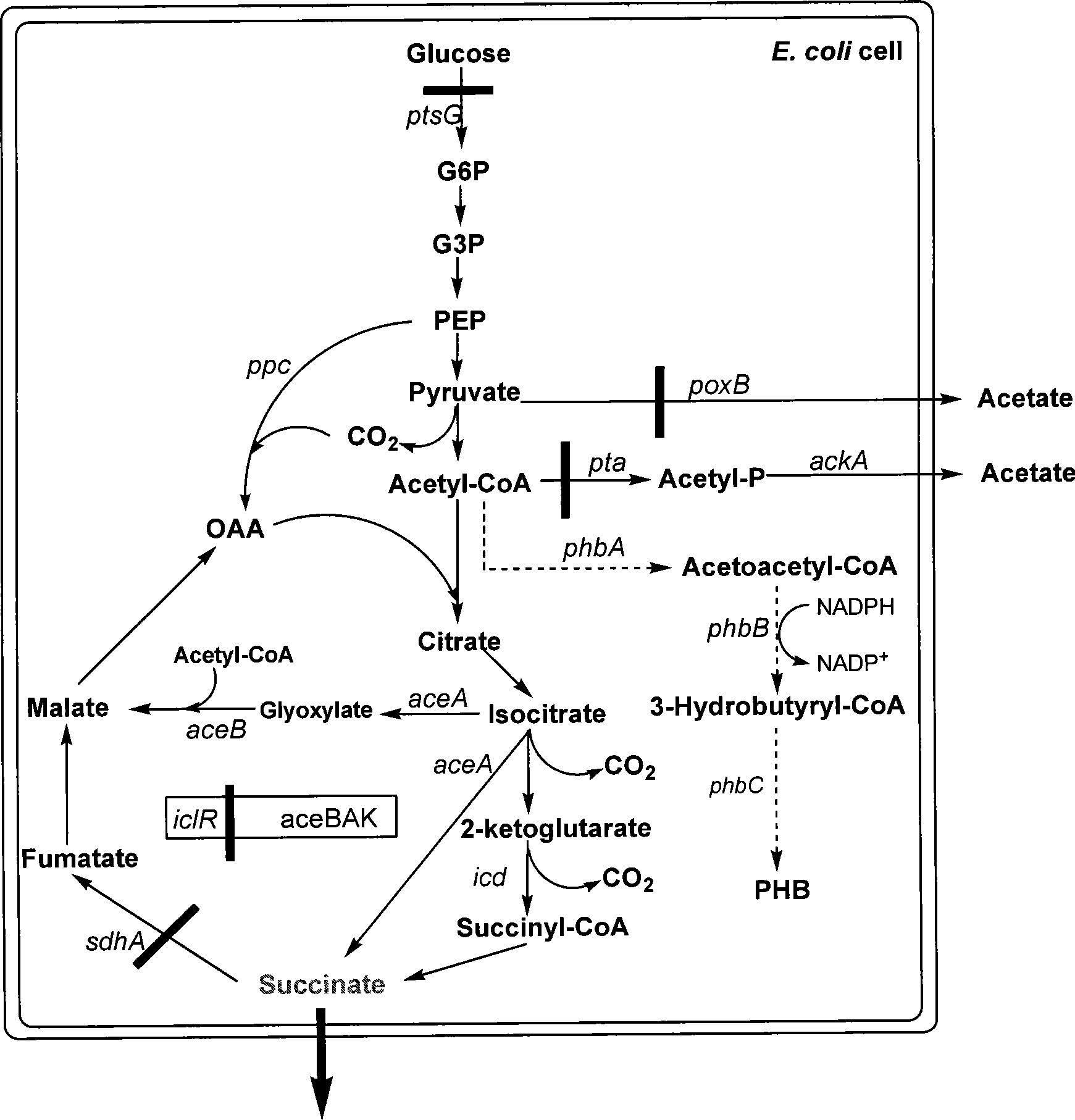

Method for coproducing succinic acid and poly beta-hydroxybutyrate using recombination of escherichia coli

A technology for recombining Escherichia coli and hydroxybutyrate, applied in the field of genetic engineering and microbial fermentation, can solve the problem of high cost of PHB

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Embodiment 1, construction of succinic acid fermentation pathway (knockout sdhAB)

[0064] Bacteria: Escherichia coli MG1655

[0065] The LB medium is: peptone 10g / L, yeast powder 5g / L, NaCl 10g / L, ampicillin 100mg / L, kanamycin 50mg / L.

[0066] The ampicillin-resistant plate is an LB solid medium containing 100 mg / L ampicillin and 1.5% agar powder.

[0067] The kanamycin-resistant plate is an LB solid medium containing 50 mg / L ampicillin and 1.5% agar powder.

[0068] The SOC medium is: peptone 2g / L, yeast powder 0.5g / L, NaCl 0.0585g / L, KCl 0.0186g / L, MgCl 2 0.203g, MgSO 4 0.246g / L, glucose 20mmol / L.

[0069] (1) Cloning of homologous recombination fragments

[0070] The gene of interest was knocked out using the Red recombination system. Primers were designed according to the sdhAB gene sequence published by Genbank:

[0071] pKD-sdhAB primer1

[0072] 5′-GGGCCACACGCGAAACTGAAACTCGATCACCTGGGTAAAGTGTAGGCTGGAGCTGCTTC-3′

[0073] pKD-sdhAB primer2

[0074] 5′-G...

Embodiment 2

[0097] Embodiment 2, the construction of PHB synthetic metabolic pathway

[0098] Bacteria: Escherichia coli DH5α

[0099] The medium LB: peptone 10g / L, yeast powder 5g / L, NaCl 10g / L, ampicillin, 100mg / L.

[0100] The PHB synthetase gene is derived from Alcaligenes eutrophus (A.eutrophus).

[0101] The ampicillin-resistant plates contained 1.5% agar and 100 mg / L ampicillin.

[0102] (1) Construction of PHB synthetase expression vector

[0103] (1) Alcaligenes eutropha was inoculated in LB medium, and the genome was extracted using a universal bacterial genome extraction kit.

[0104] (II) According to the genome sequence of Alcaligenes eutropha published by Genbank, design primers:

[0105] phbCAB primer 1: 5′-ATCCCCGGGGCGACCGGCAAAGGCGCGGCAGCTTCCA-3′

[0106] phbCAB primer 2: 5′-ATGGAATTCCAGCCCATATGCAGGCCGCCGTTGAGC-3′

[0107] (II) Cloning of PHB synthase gene

[0108] Using the genome of Alcaligenes eutropha as a template, the phbCAB gene was amplified by PCR. PCR rea...

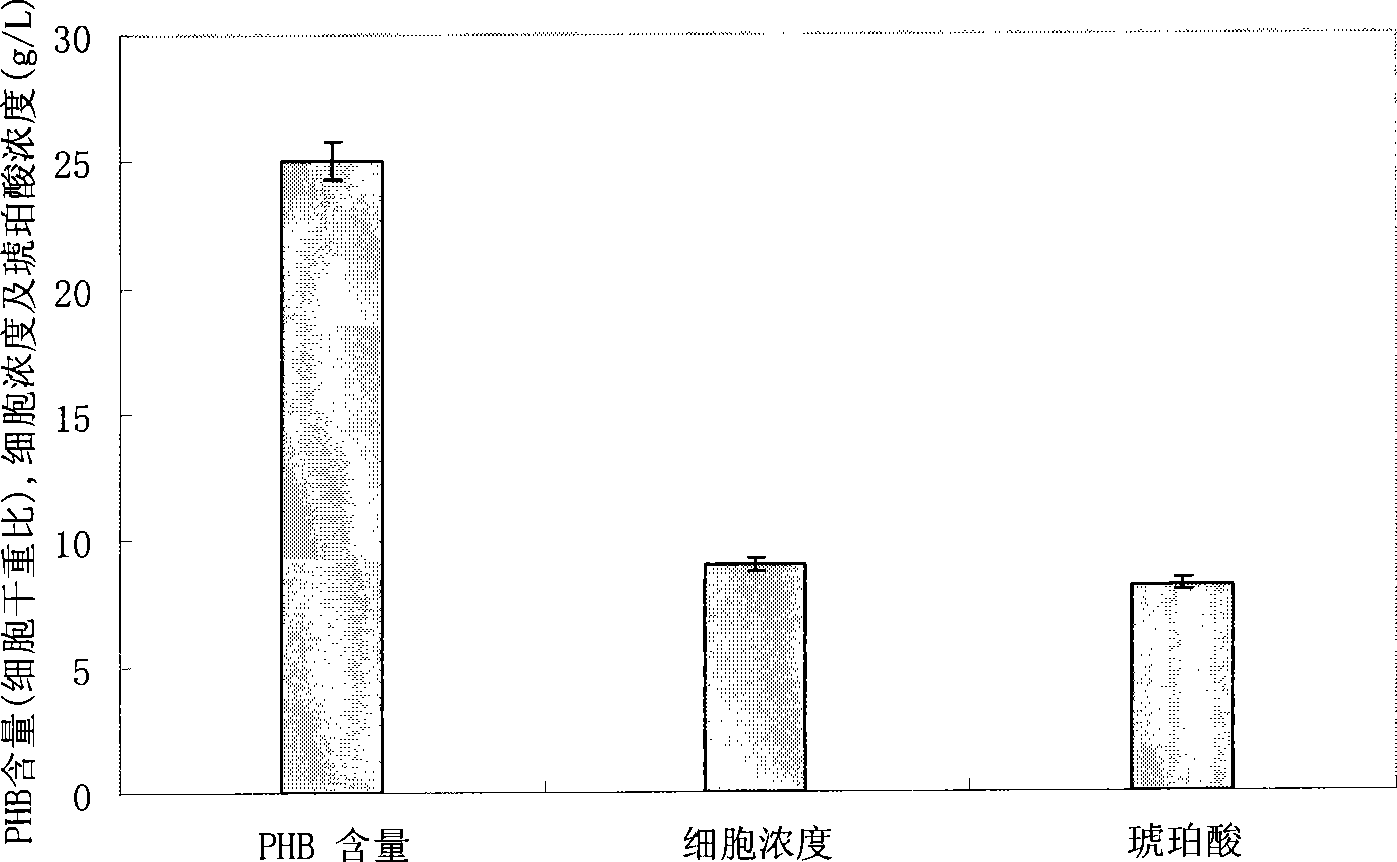

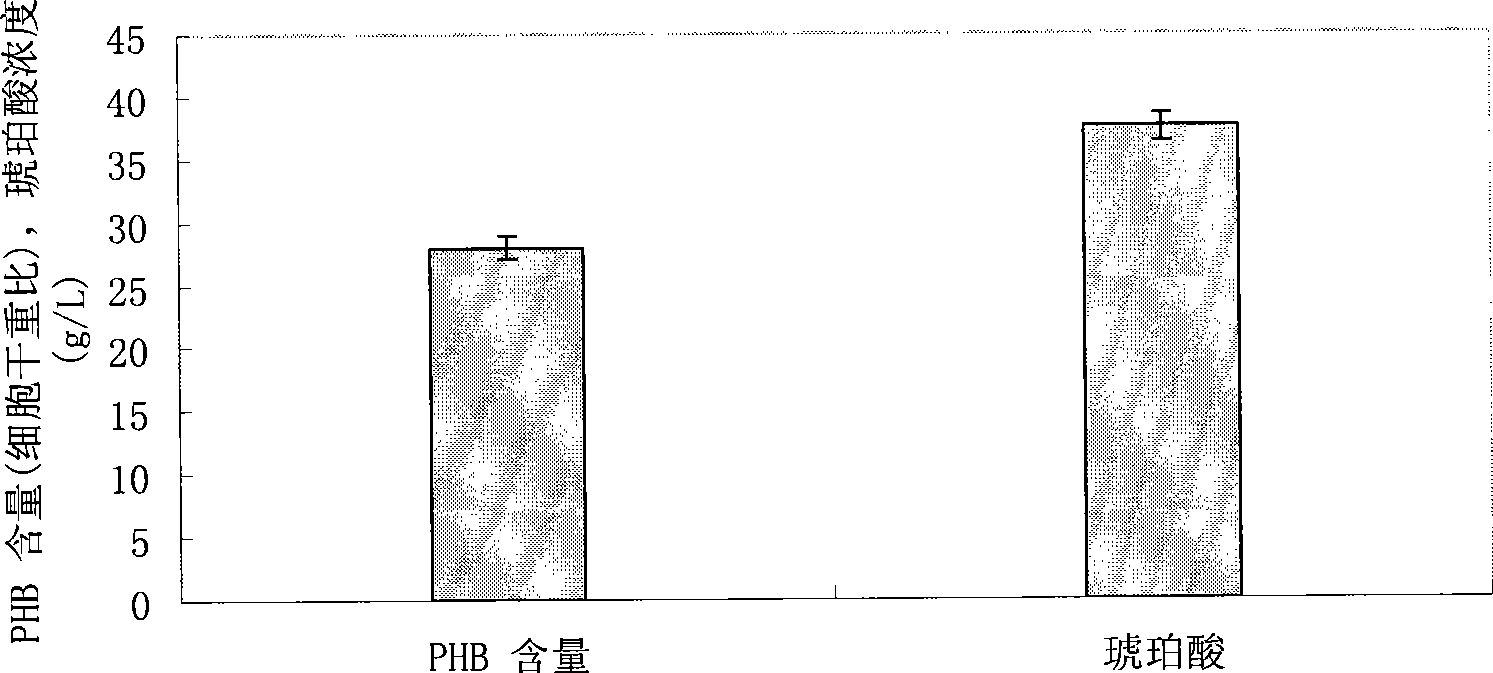

Embodiment 3

[0128] Example 3, Construction of recombinant Escherichia coli co-producing fermentative succinic acid and PHB

[0129] 1. Construction of succinate synthesis pathway (knockout of iclR gene):

[0130] Bacteria: Escherichia coli MG1655△sdhAB

[0131] (I) Cloning of homologous recombination fragments

[0132] Primers were designed according to the Escherichia coli genome sequence published by GenBank

[0133] pKD-iclR primer1:

[0134] 5′-ATGAAAATGATTTCCACGATACAGAAAAAAGACTGTCGTGTAGGCTGGAGCTGCTTC-3′

[0135] pKD-iclR primer2:

[0136] 5′-TATGATGGGCAGAATATTGCCTCTGCCCGCCAGAAAAAGATGGGAATTAGCCATGGTCC-3′, the recombinant fragment with kanamycin resistance was amplified in vitro by PCR (polymerase chain reaction) using pKD4 plasmid as a template. PCR reaction system is as follows: (primer concentration is 20 μ mol / L)

[0137] 5 μl of 10× buffer;

[0138] 25mmol / LMgCl2 4μl;

[0139] 1μl of 10mmol / L four kinds of dNTP mixture;

[0140] 1 μl each of upstream and downstream primer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com