Preparation method for three-dimensional ordered stephanoporate chitosan bone renovating bracket material

A technology of porous chitosan and three-dimensional order, which is applied in the field of preparation of scaffold materials for bone repair, can solve the problems of uneven pore size distribution, low strength, disordered structure, etc., and achieve high strength and porosity, good regularity, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1) take by weighing 20g chitosan powder and be dissolved in 500ml volume fraction and be 2% dilute acetic acid, make mass fraction be the chitosan solution of 4%, leave standstill for defoaming;

[0020] 2) uniformly coating the chitosan solution in step 1) on the surface of the mold, placing the mold in a NaOH coagulation solution with a mass fraction of 5%, coagulating the chitosan into a film at room temperature, and demoulding to obtain a chitosan film template;

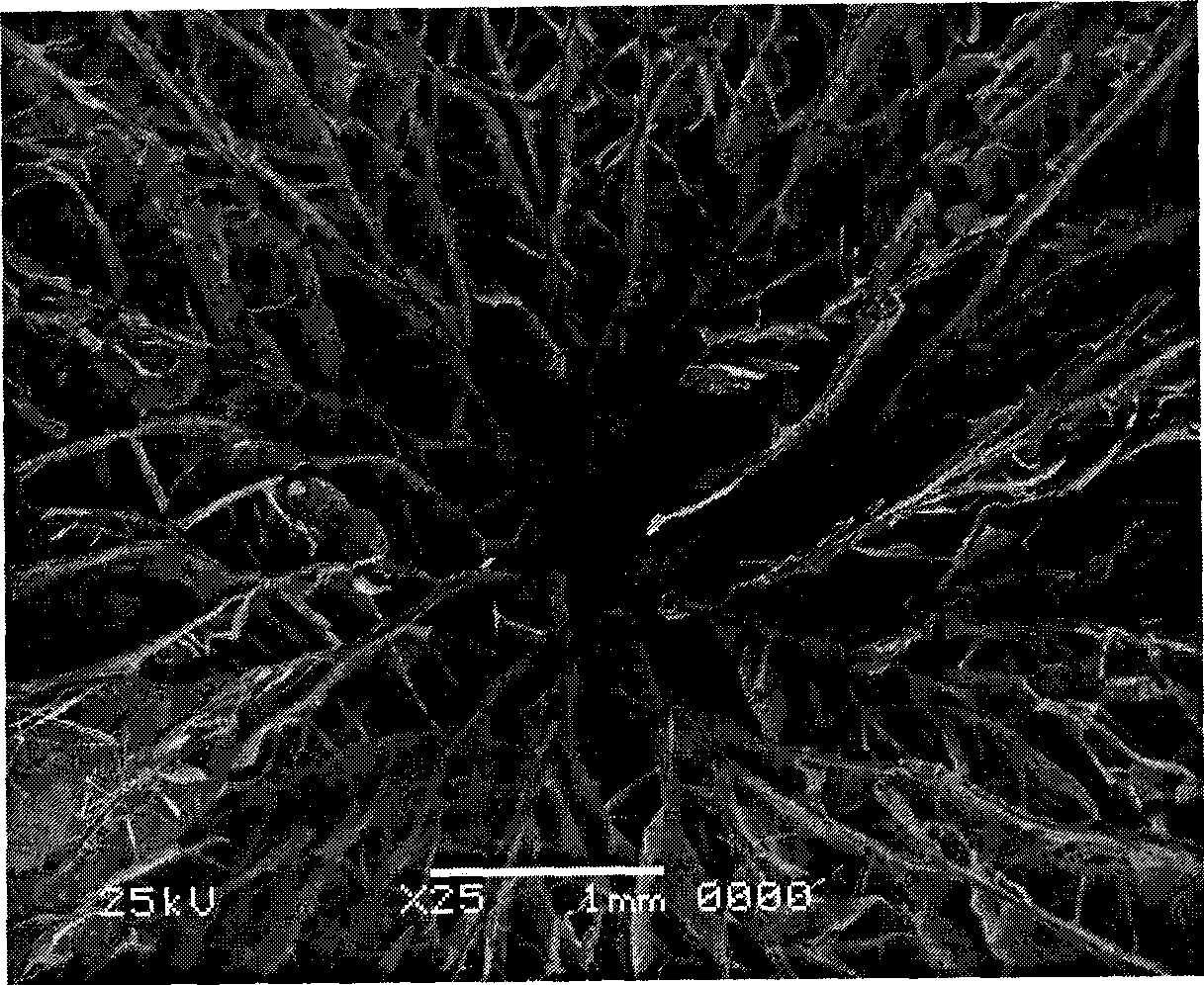

[0021] 3) Pour the chitosan solution prepared in step 1) into the chitosan membrane template, seal the seal, and immerse in a 5% NaOH coagulation solution with a mass fraction, solidify for 4h, and demould to obtain a chitosan gel, Its cross-section is as figure 1 As shown in , the ordered structure of concentric circles can be seen, and the longitudinal section is as follows figure 2 As shown, the layered superposition order structure can be seen;

[0022] 4) Wash the chitosan gel with distilled water...

Embodiment 2

[0027] 1) taking by weighing 25g chitosan powder is dissolved in the dilute acetic acid that volume fraction is 2%, makes the chitosan solution that mass fraction is 5%, leaves standstill defoaming;

[0028] 2) uniformly coating the chitosan solution in step 1) on the surface of the mold, placing the mold in a NaOH coagulation solution with a mass fraction of 5%, coagulating the chitosan into a film at room temperature, and demoulding to obtain a chitosan film template;

[0029] 3) Pour the chitosan solution prepared in step 1) into the chitosan film template, seal it, and immerse it in a 5% NaOH coagulation solution with a mass fraction, solidify for 8 hours, and demould to obtain a chitosan gel;

[0030] 4) The chitosan gel was washed with distilled water until neutral, dried in an oven at 70°C for 90 minutes, and then freeze-dried in a freeze dryer at -70°C for 60 hours to obtain a three-dimensional ordered porous chitosan scaffold.

[0031] Measured results: Porosity: 62%...

Embodiment 3

[0035] 1) Weigh 25g of chitosan powder and dissolve it in dilute acetic acid with a volume fraction of 2%, to make a chitosan solution with a mass fraction of 5%, and let it stand for defoaming.

[0036] 2) uniformly coating the chitosan solution in step 1) on the surface of the mold, placing the mold in a KOH coagulation solution with a mass fraction of 5%, coagulating the chitosan at room temperature to form a film, and demoulding to obtain a chitosan film template ;

[0037] 3) pour the chitosan solution prepared in step 1) into the chitosan film template, seal, and immerse in a 5% KOH coagulation solution with a mass fraction, solidify for 4 hours, and demould to obtain a chitosan gel;

[0038] 4) The chitosan gel was washed with distilled water until neutral, dried in an oven at 80°C for 60 minutes, and then freeze-dried in a freeze dryer at -70°C for 72 hours to obtain a porous chitosan scaffold.

[0039] Measured results: porosity: 70%

[0040] Compression s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com