Treatment method and apparatus for purifying water with sewage sludge adsorption

A sewage treatment method and sludge adsorption technology, applied in the direction of adsorption water/sewage treatment, water/sludge/sewage treatment, biological water/sewage treatment, etc., can solve the problems of aeration treatment, increase the load of the primary sedimentation tank, etc. , to avoid odor emission, increase sludge activity, and reduce the concentration of organic matter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

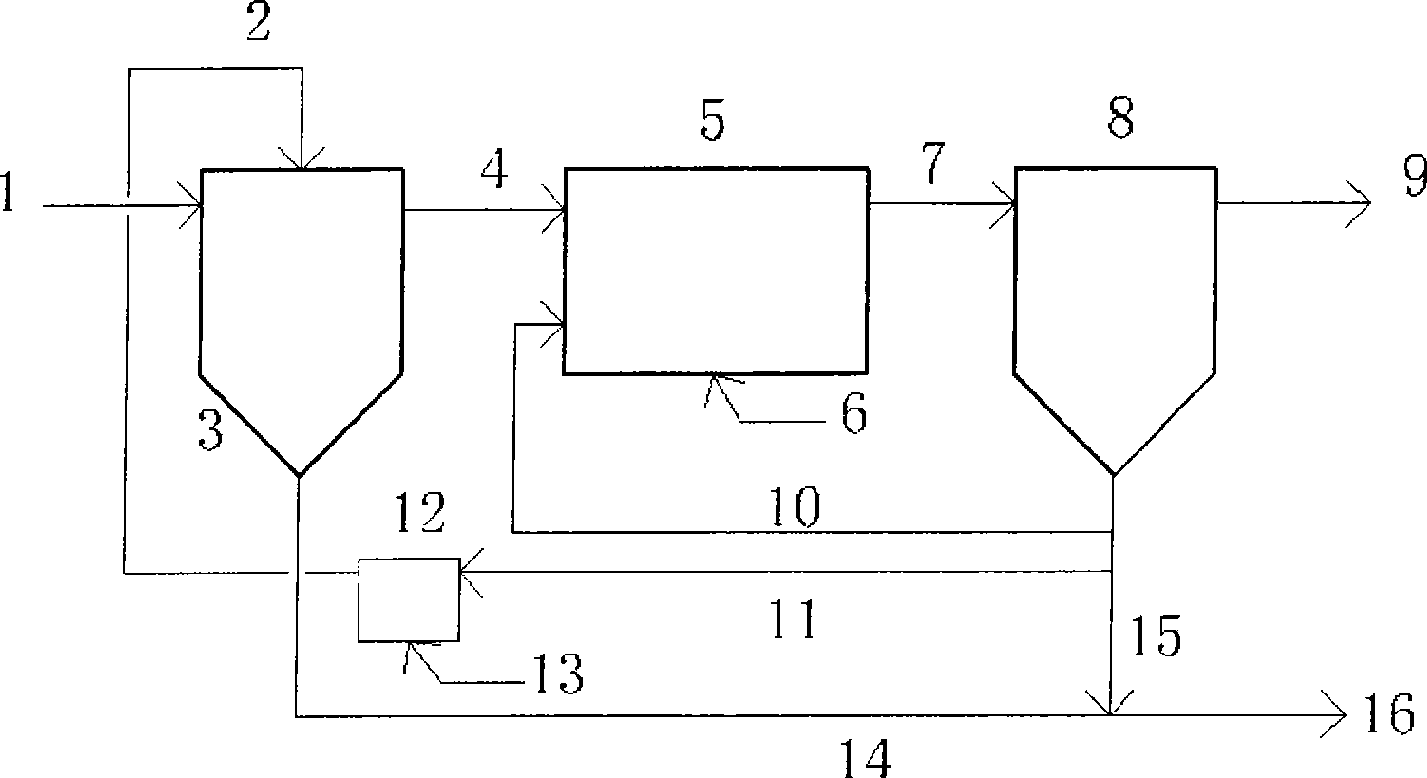

Embodiment 1

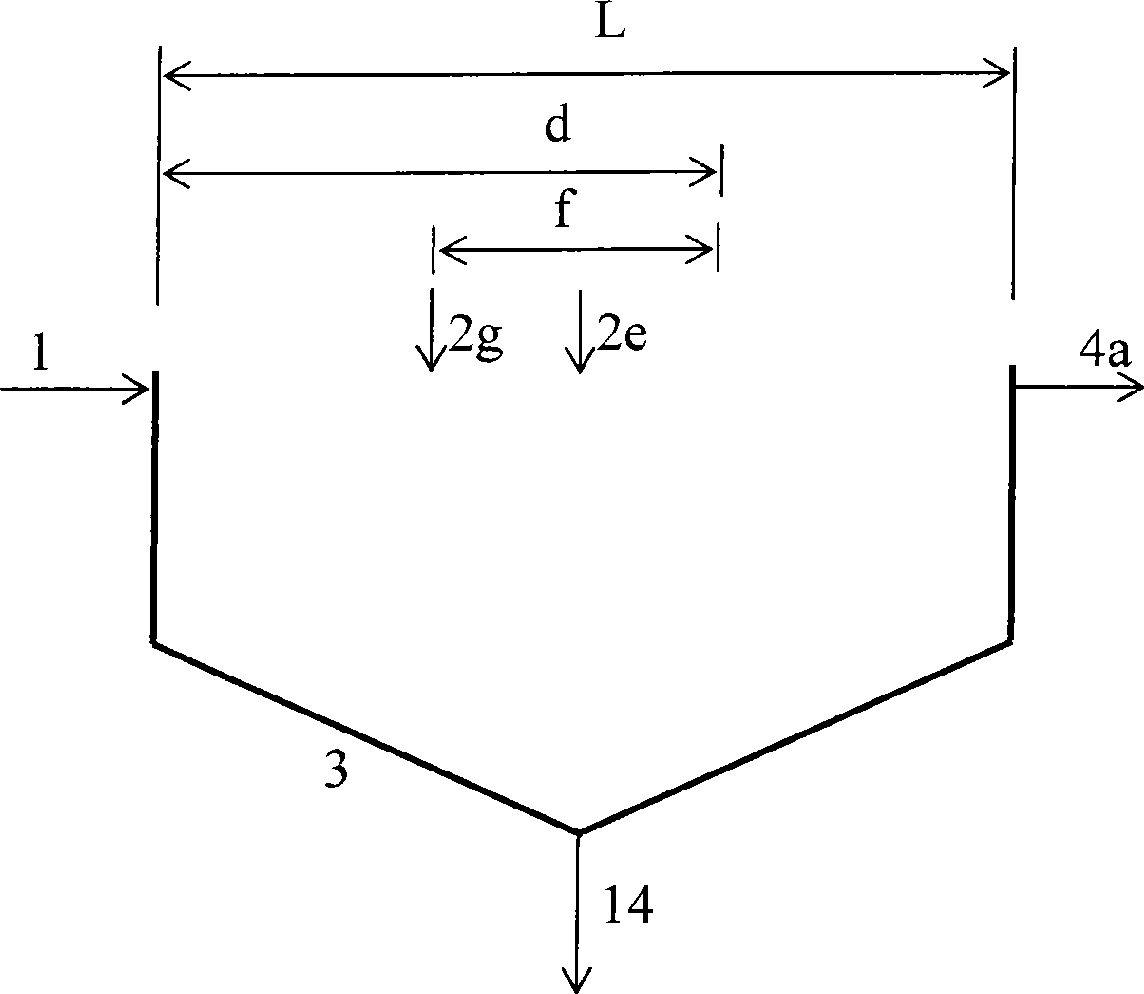

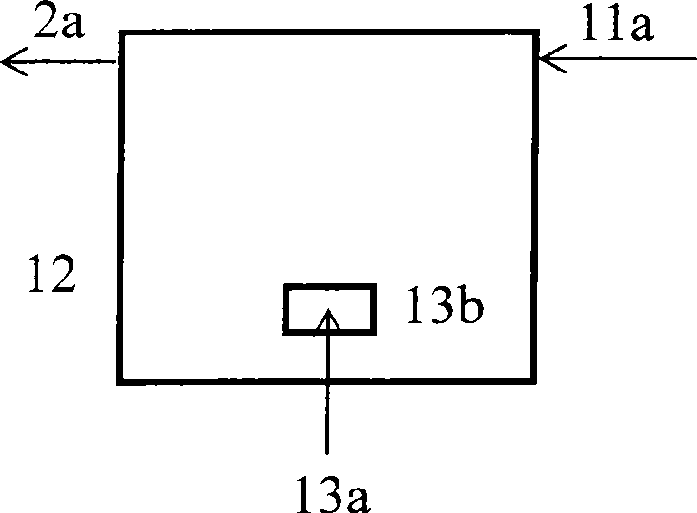

[0023] process such as image 3 shown. The excess sludge discharged from the secondary sedimentation tank is introduced into the sludge modified aeration tank 12 through the sludge inlet 11a, and the air 13 is aerated through the air inlet 13a and the aerator 13b, and the dissolved oxygen concentration in the aeration is 0.5mg / L, the aeration time is maintained for 1h, and then the modified sludge 2 is sent to the position 2e of the primary sedimentation tank 3, which is about 1 / 2 the length of the inlet and outlet of the primary sedimentation tank 3, through the sludge outlet 2a Mixed with sewage in the pool, such as figure 2 As shown, within the hydraulic retention time of the primary sedimentation tank, it is fully mixed with the sewage after adsorption and then settles, and the mud and water are separated. The adsorption supernatant is used as the effluent of the primary sedimentation tank and enters the aeration tank for further aerobic treatment. After adsorption, the ...

Embodiment 2

[0025] The remaining sludge discharged from the secondary sedimentation tank is introduced into the sludge modified aeration tank for aeration regeneration treatment, the dissolved oxygen concentration in the aeration is 1.0mg / L, the aeration time is maintained at 0.5h, and then the sludge is returned to the 2g away from the water inlet of the primary sedimentation tank, which is about 1 / 3 of the length of the inlet and outlet of the tank, so that the sludge concentration in the tank is maintained at 400-600mg / L. During the hydraulic retention time of the primary sedimentation tank, it is fully mixed with sewage and then settled , mud and water are separated, and the adsorption supernatant is used as the effluent of the primary sedimentation tank and enters the aeration tank for further aerobic treatment. After adsorption, the precipitated sludge enters the sludge treatment system. Compared with the effluent without adding sludge and the natural sedimentation of the primary sed...

Embodiment 3

[0027] The process conditions are the same as in Example 1, except that the sludge modified aeration tank 12 is not set in the process engineering, that is, the sludge discharged from the secondary sedimentation tank 8 is directly sent to the primary sedimentation tank 3 for adsorption and precipitation. When the biological oxidation load is low and the volume of the secondary sedimentation tank is relatively small, the sludge discharge is timely, and the sludge discharge of the primary sedimentation tank is timely, sludge adsorption and purification can also be achieved without sludge modification and aeration.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com