Modified ardealite setting retarder for cement and its preparing process

A cement retarder, phosphogypsum technology, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of long natural drying storage time, small amount of phosphogypsum, slow cement speed, etc. , to achieve significant social benefits, short storage time, and promote the effect of cement coagulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

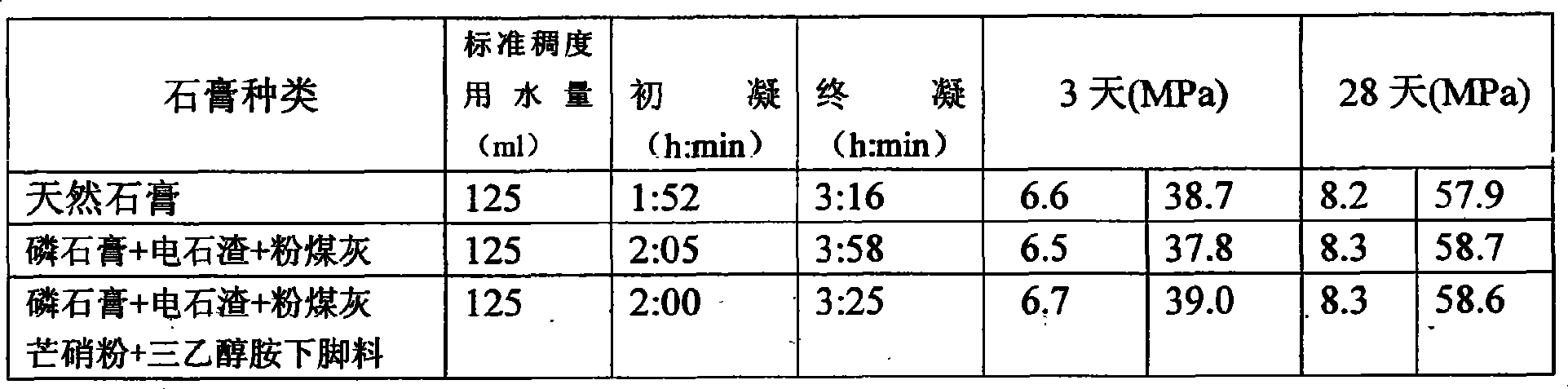

Examples

Embodiment 11

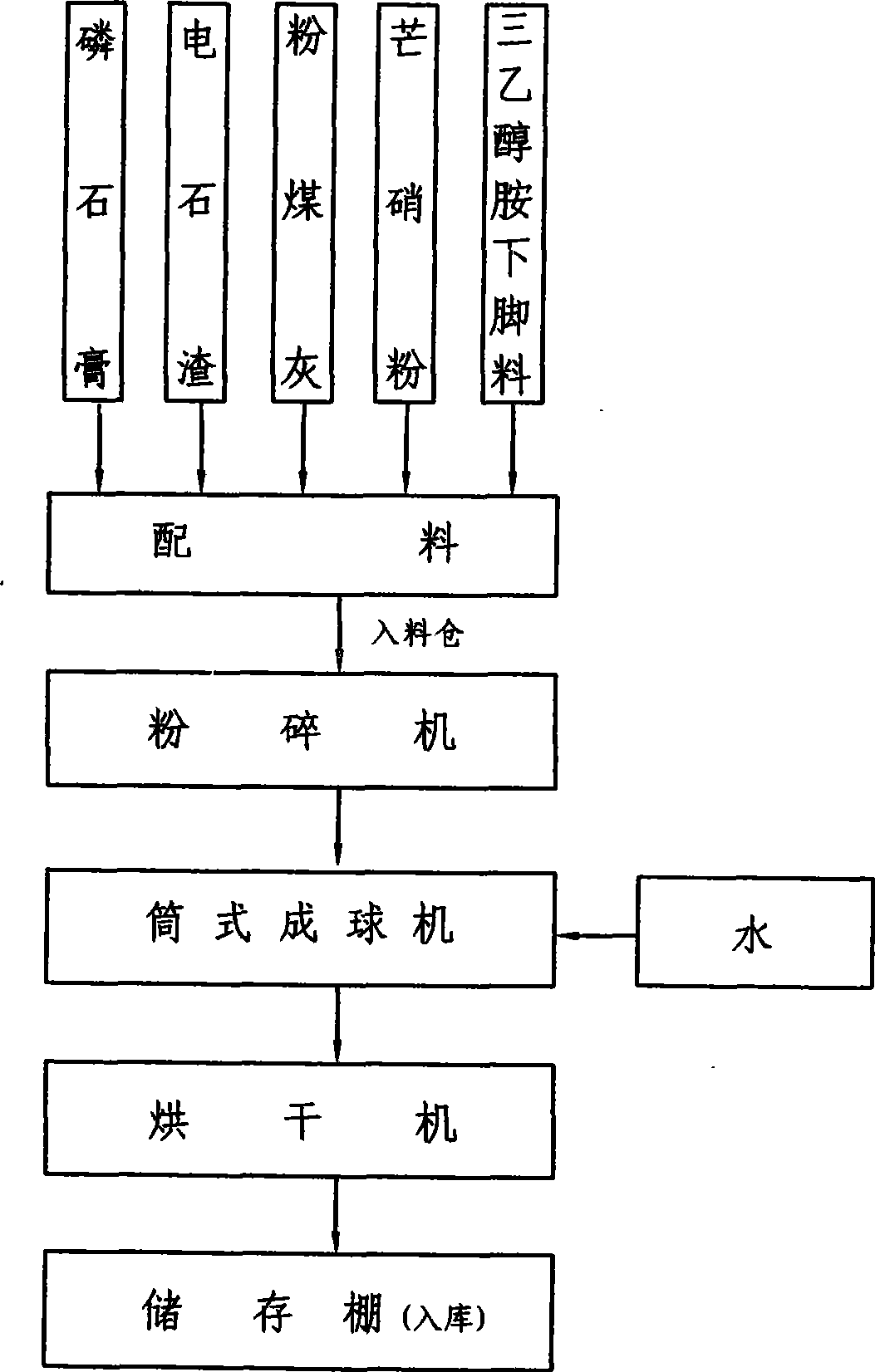

[0027] The preparation method of this modified phosphogypsum cement retarder, see figure 1 :

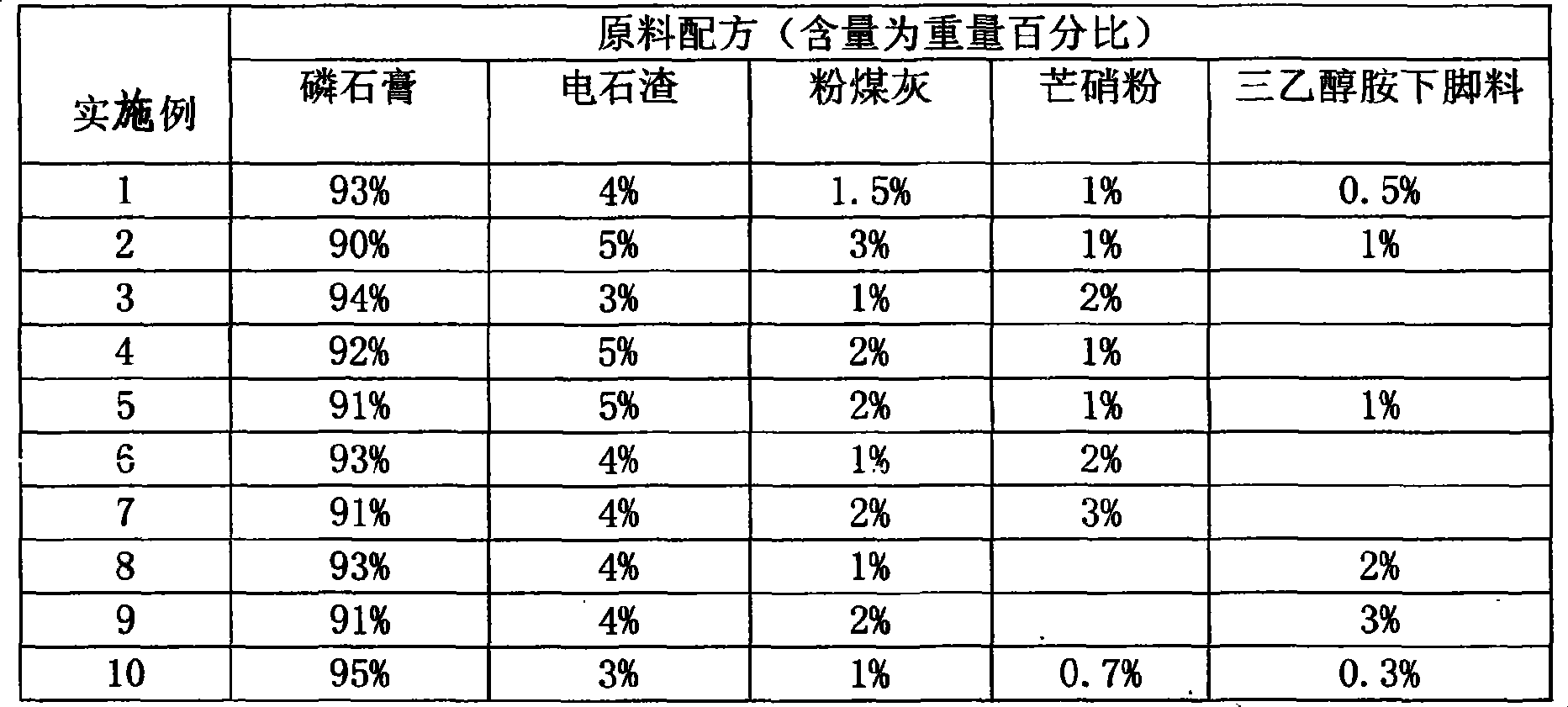

[0028] Select embodiment 1~10 batching, earlier with forklift, calcium carbide slag, fly ash, Glauber's salt powder (mineral powder) and / or triethanolamine amine leftovers are mixed homogeneously; Mix evenly according to the proportion, enter the hopper, and send the belt conveyor to the pulverizer for crushing until the particle size is ≤1mm. Add water, and further homogenize into balls (the balls contain 18% water), and the wet balls are sent to the dryer with a belt conveyor, dried with a dryer until the water content is 14%, and the discharge temperature is ≤100°C, and then conveyed by a belt The machine is sent to the storage shed for storage.

[0029] Send the wet material into the dryer and dry it until the water content is 14%. The drying temperature of the material discharged from the dryer is ≤100°C. The moisture in the ball is too large, and all the above-mentioned equi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com