Grinding processing method and grinding processing device

A grinding process and grinding technology, which is applied in the direction of spraying devices, explosion generating devices, metal processing equipment, etc., can solve problems such as uneven processing, achieve the effect of reducing the amount of grinding and increasing the number of regenerations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0197] (embodiment 1; processing method: Figure 15 (A))

[0198]

[0199] The film formed on the surface of the test wafer was removed, and a uniform smooth mirror surface without processing unevenness was formed on the wafer surface, and mirror polishing by a polishing device was not required. Therefore, the time required for wafer polishing can be greatly shortened, and a polishing apparatus is not required. Furthermore, since the film formed on the wafer can be efficiently removed, the wafer can be regenerated.

[0200] 【table 3】

Embodiment 2

[0201] (embodiment 2; processing method: Figure 15 (B))

[0202]

[0203] (embodiment 2; processing method: Figure 15 (B))

[0204]

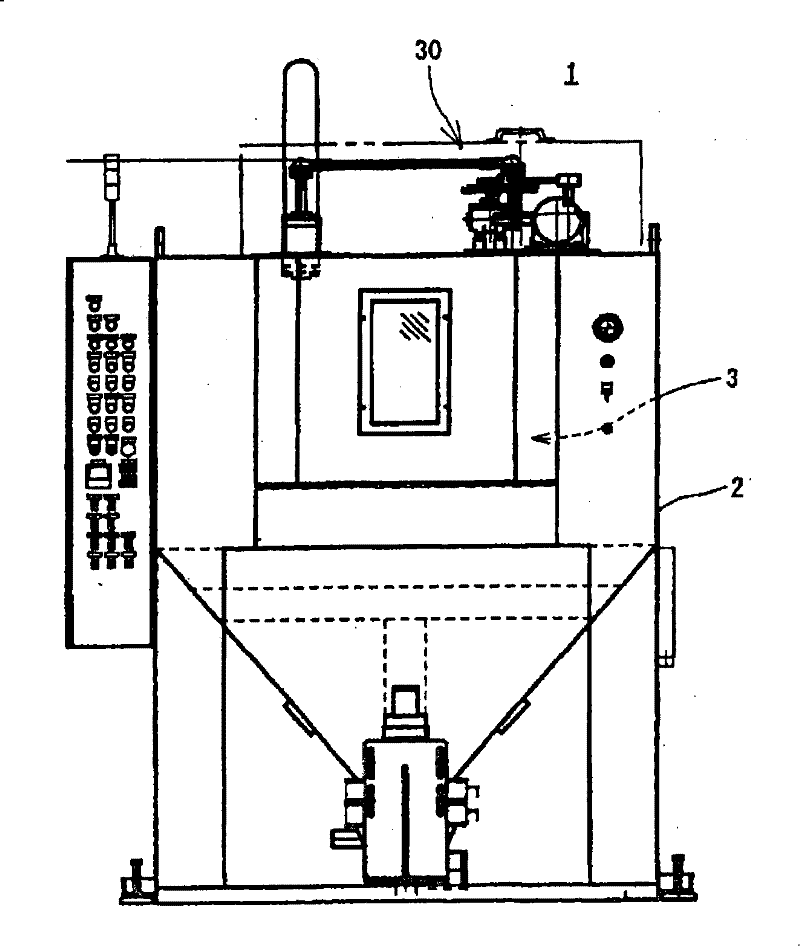

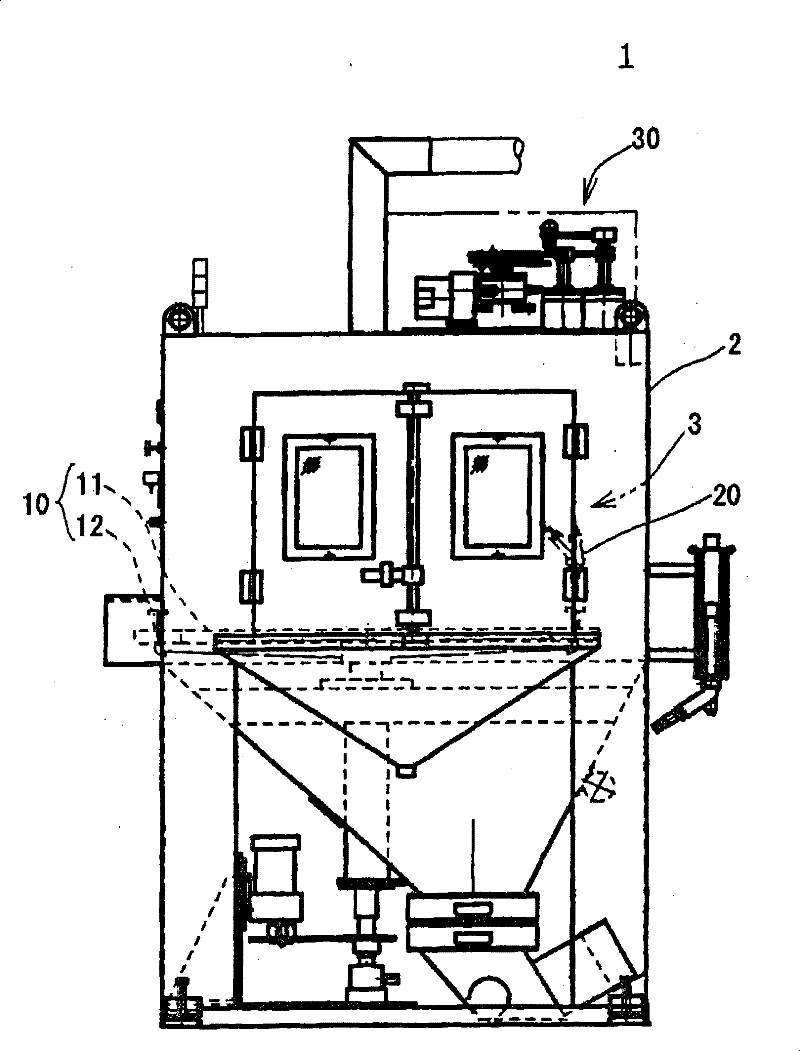

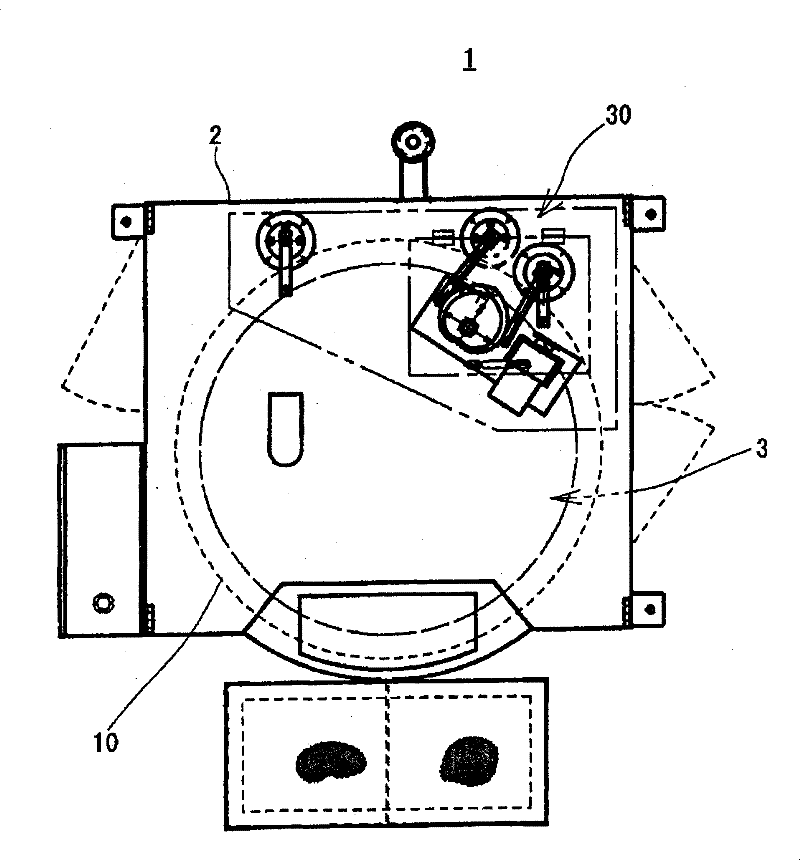

[0205] The following devices are connected to the spray processing device 1 constituted as described above: an unshown compressed air supply source such as an air compressor; Produced dust etc. are sucked; And cyclone separator 60, it is used for reclaiming the ground material after removing dust from the grinding material mixed with dust that is sucked from processing chamber 3 by this dust collector 50, constructs Such as Figure 14 A processing system for spray processing a wafer W is shown.

[0206] Furthermore, while opening the opening and closing door on the casing 2 of the spray processing apparatus 1, the wafer W is mounted on the chuck 12 arranged on the turntable 11 in the casing 2, and the spray processing apparatus 1 is started, then Utilize the nozzle 20 installed on the rocker arm 31 (31a, 31b, 31c) to spray the abrasiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com