Improved type A<2>/O or invert A<2>/O technique

An improved and technological technology, applied in water/sludge/sewage treatment, aerobic and anaerobic process treatment, flocculation/sedimentation water/sewage treatment, etc. Inconsistent time, inability to remove phosphorus and nitrogen, etc., to achieve excellent phosphorus and nitrogen removal effects, perfect and convenient layout, and improve treatment efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

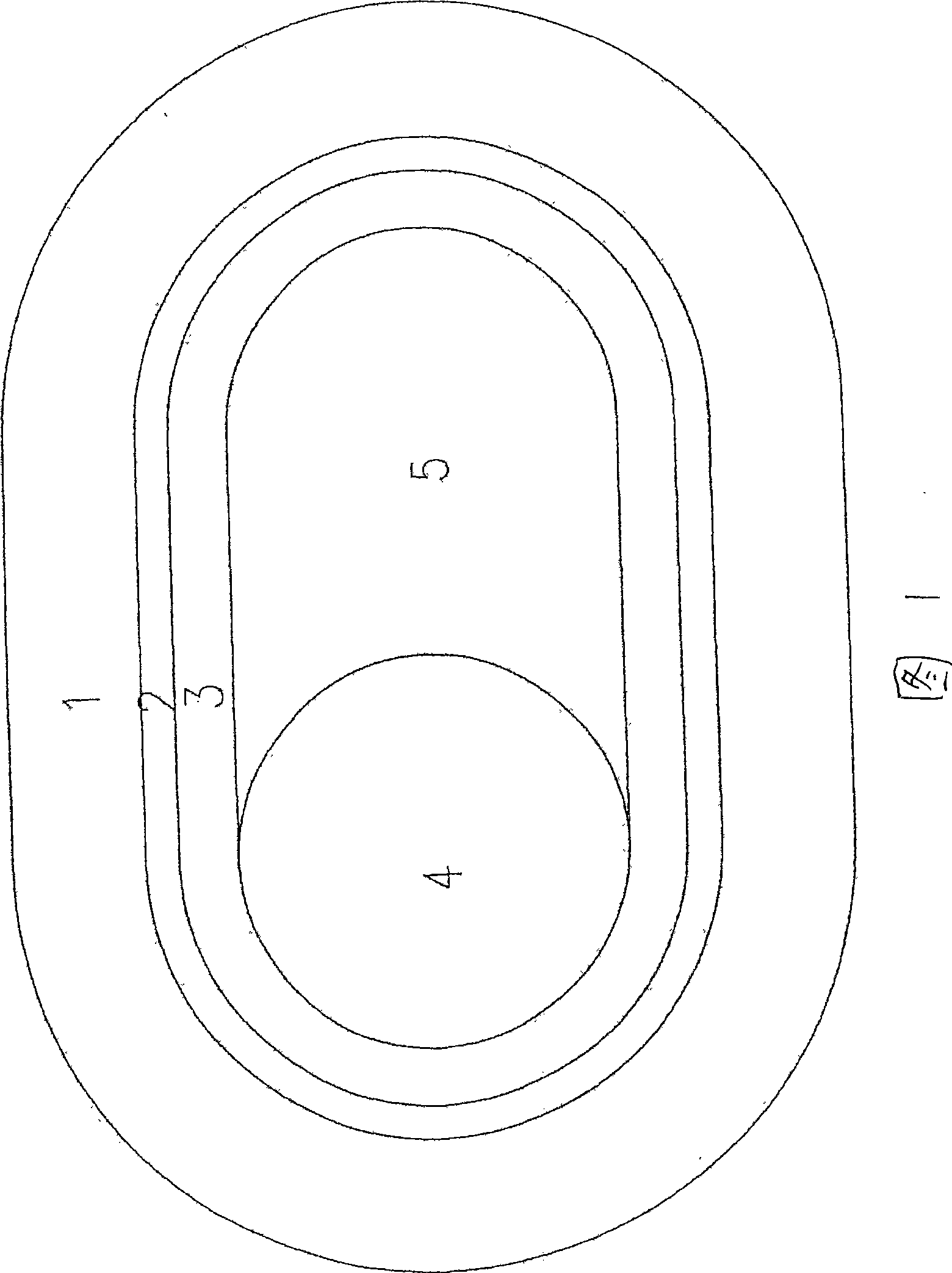

[0012] Embodiment 1, improved type A 2 / O, designed as an oxidation ditch, including outer ditch 1, middle ditch 2, inner ditch 3 and central island area, one end of the central island area is designed with a secondary settling tank 4, and the secondary settling tank 4 shares a semicircular wall with the inner wall of the inner ditch body, the space between the outer wall of the secondary settling tank and the inner wall of the inner ditch is designed as a sludge return area 5, the sewage first enters the anaerobic tank of the inner ditch, then enters the anoxic tank of the middle ditch, the aerobic tank of the outer ditch, and finally enters the secondary settling tank 4 discharge, part of the sludge in the secondary settling tank 4 circulates through the sludge return zone 5 and enters the anaerobic tank of the inner ditch 3 .

Embodiment 2

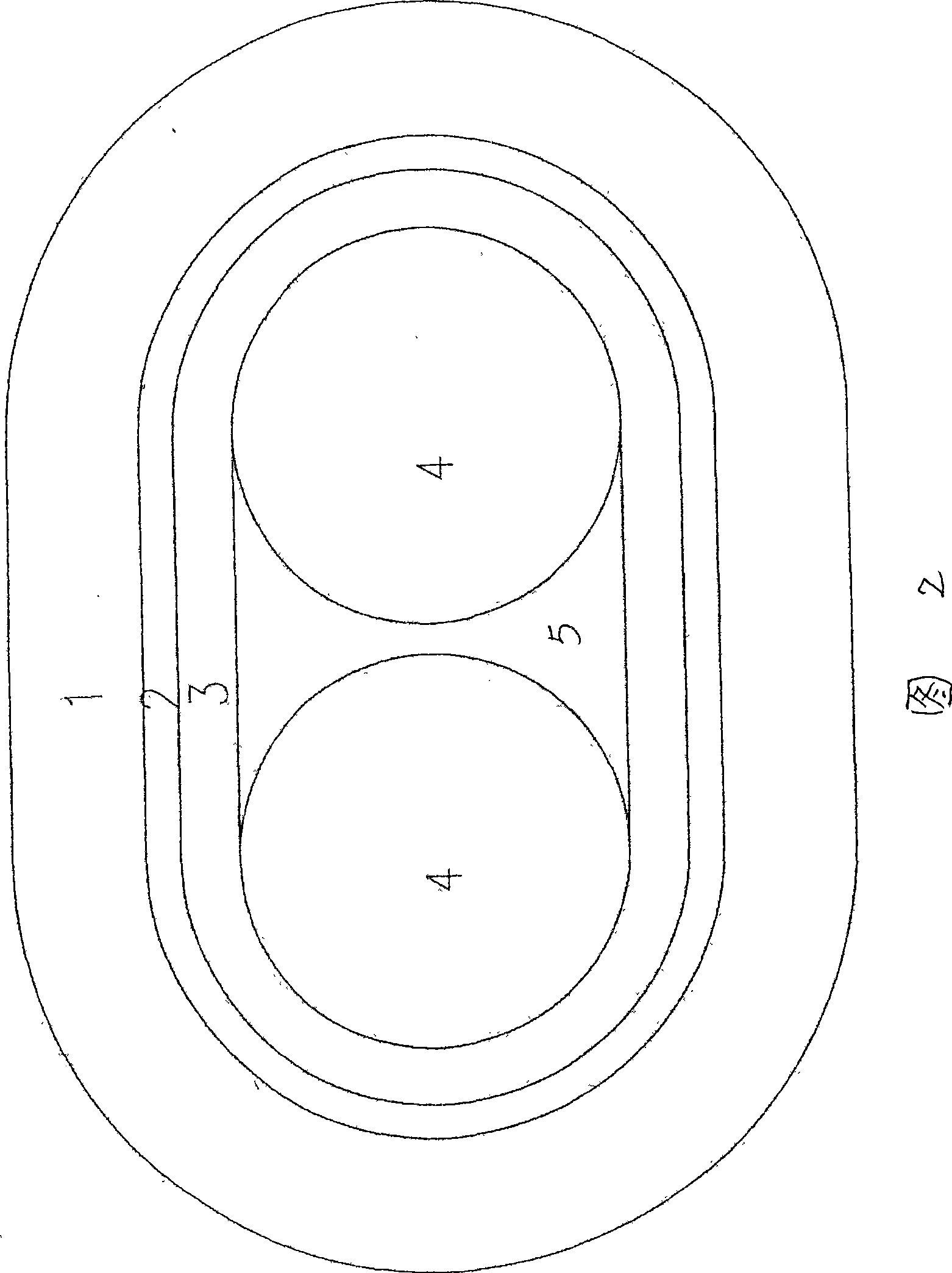

[0013] Embodiment 2, improved inversion A 2 / O process, designed for oxidation ditch type, including outer ditch 1, middle ditch 2, inner ditch 3 and central island area, two ends of the central island area are respectively designed with a secondary settling tank 4, two ends of the secondary settling tank 4 and the inner ditch The inner wall shares the semicircular wall, and the space between the outer wall of the secondary settling tank 4 and the inner wall of the inner ditch is designed as a sludge return area 5. The sewage first enters the inner ditch anoxic tank, then enters the middle ditch anaerobic tank, the outer ditch aerobic tank, and finally Enter the secondary settling tank 4 for discharge, and part of the sludge in the secondary settling tank 4 circulates into the inner ditch anoxic tank through the sludge return area.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com