CaO-MgO-SiO2 series fluorescent glass-ceramics and preparation method thereof

A technology of glass-ceramics and fluorescence, which is applied in the field of luminescent materials and its preparation, can solve the problems of weak luminous intensity and low conversion efficiency of glass materials, and achieve the effect of poor color stability and excellent luminous performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

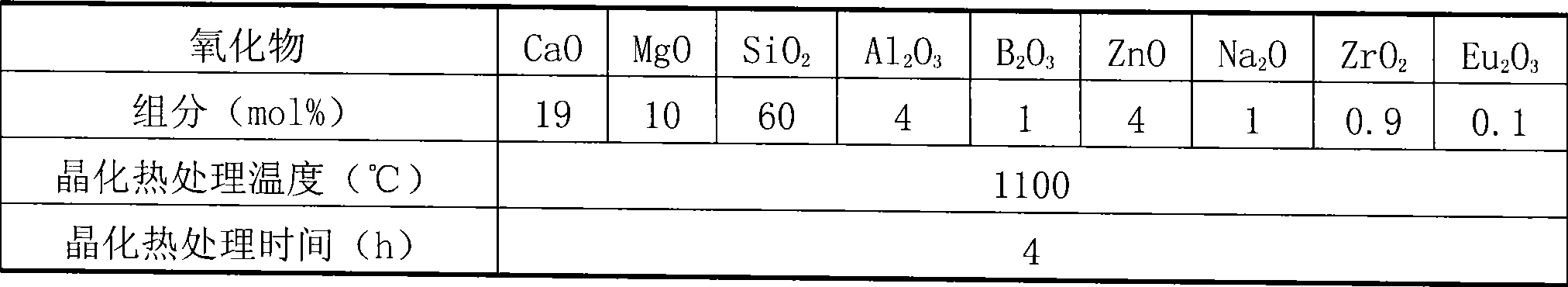

[0028] CaO-MgO-SiO 2 Fluorescent glass-ceramic, which contains CaO, MgO, SiO 2 、Al 2 o 3 , B 2 o 3 , ZnO, Na 2 O, ZrO 2 and Eu 2 o 3 The raw materials are prepared; the mole percentage of each raw material is shown in Table 1.

[0029] Table 1

[0030]

[0031] The specific preparation process is as follows: First, weigh 50 g of pure raw materials for analysis according to the formula in Table 1, mix the raw materials evenly, pour them into a corundum crucible, and melt them under a reducing atmosphere at a melting temperature of 1550 ° C. Put it into a heat-resistant mold, anneal in a muffle furnace, and keep it at the glass transition temperature Tg (550°C) for 1 hour, then cool down with the furnace, and take out the glass. After that, put the prepared glass in a precision annealing furnace for heat treatment at 1100°C for 4 hours, turn off the power of the precision annealing furnace and automatically lower it to room temperature to obtain ...

Embodiment 2

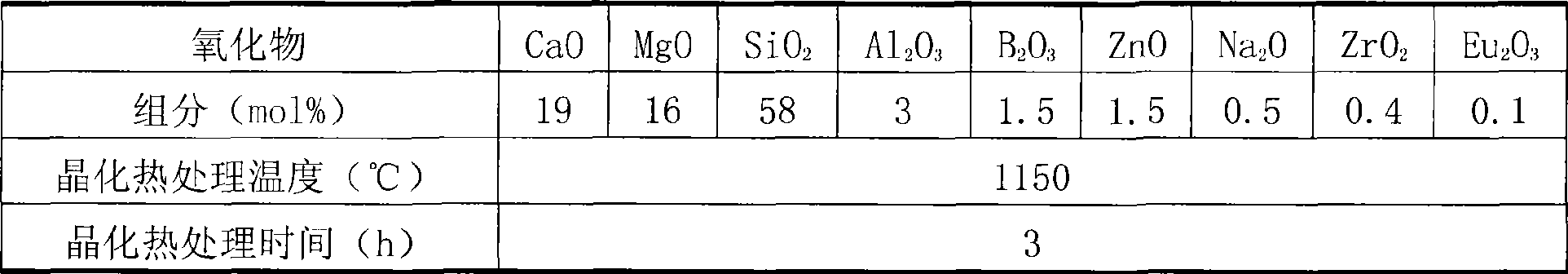

[0034] CaO-MgO-SiO 2 Fluorescent glass-ceramic, which contains CaO, MgO, SiO 2 、Al 2 o 3 , B 2 o 3 , ZnO, Na 2 O, ZrO 2 and Eu 2 o 3 The raw materials are prepared; the mole percentage of each raw material is shown in Table 2.

[0035] Table 2

[0036]

[0037] The specific preparation process is as follows: First, weigh 50 g of the pure raw material for analysis according to the formula in Table 2, mix the raw material evenly, pour it into a corundum crucible and melt it, and melt it under a reducing atmosphere at a melting temperature of 1500 ° C for 2 hours. The liquid is poured into cold water, the water-quenched glass is ground, passed through a 200-mesh sieve, and then pressed into a steel mold under 80MPa, and the glass is taken out for crystallization heat treatment. After that, place the pressed glass sheet in a precision annealing furnace for heat treatment at 1150°C for 3 hours, turn off the power of the precision annealing furnace a...

Embodiment 3

[0040] CaO-MgO-SiO 2 The preparation method of fluorescent glass-ceramic, it comprises the steps:

[0041] 1) Selection of raw materials, according to the mole percentage of each raw material: CaO: 15%, MgO: 15%, SiO 2 : 56%, Al 2 o 3 : 5%, ZnO: 4%, Eu 2 o 3 : 5%, take the raw material and set aside;

[0042] 2) CaO, MgO, SiO 2 、Al 2 o 3 , ZnO and Eu 2 o 3 After mixing the raw materials evenly, pour them into a corundum crucible, and melt them in a reducing atmosphere at a melting temperature of 1400°C and keep them warm for 1 hour to obtain molten glass;

[0043] 3) Pour the molten glass into a heat-resistant mold, and keep it in the muffle furnace at the glass transition temperature Tg (600°C) for 1 hour; turn off the power of the muffle furnace and automatically lower it to room temperature, and take out the glass (for crystallization treatment) ;

[0044] 4) Put the glass in a precision annealing furnace for heat treatment at 1000°C for 1 hour, turn off the pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com