Thin-film solar cell module and processing method thereof

A technology of thin-film solar cells and processing methods, which is applied in the direction of sustainable manufacturing/processing, circuits, photovoltaic power generation, etc., can solve the problems of lengthening process time, high difficulty of scribing, and complicated process steps, so as to reduce process time and reduce Pollution, the effect of simplifying process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

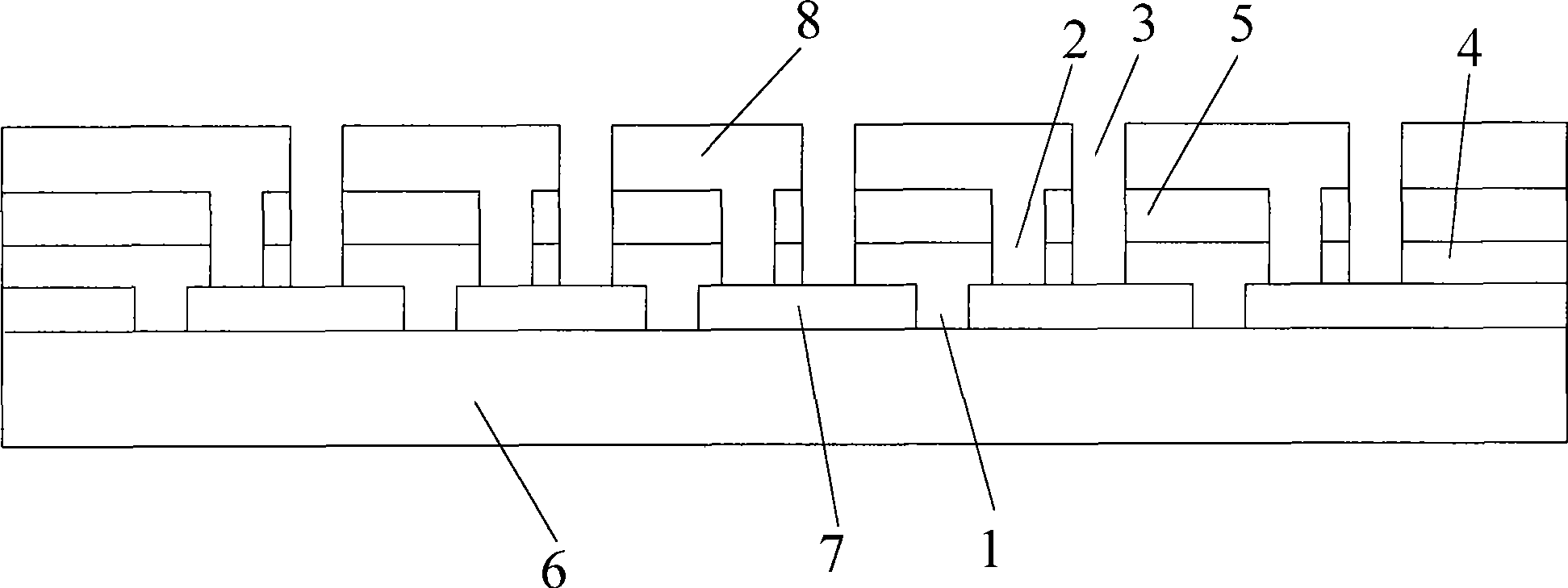

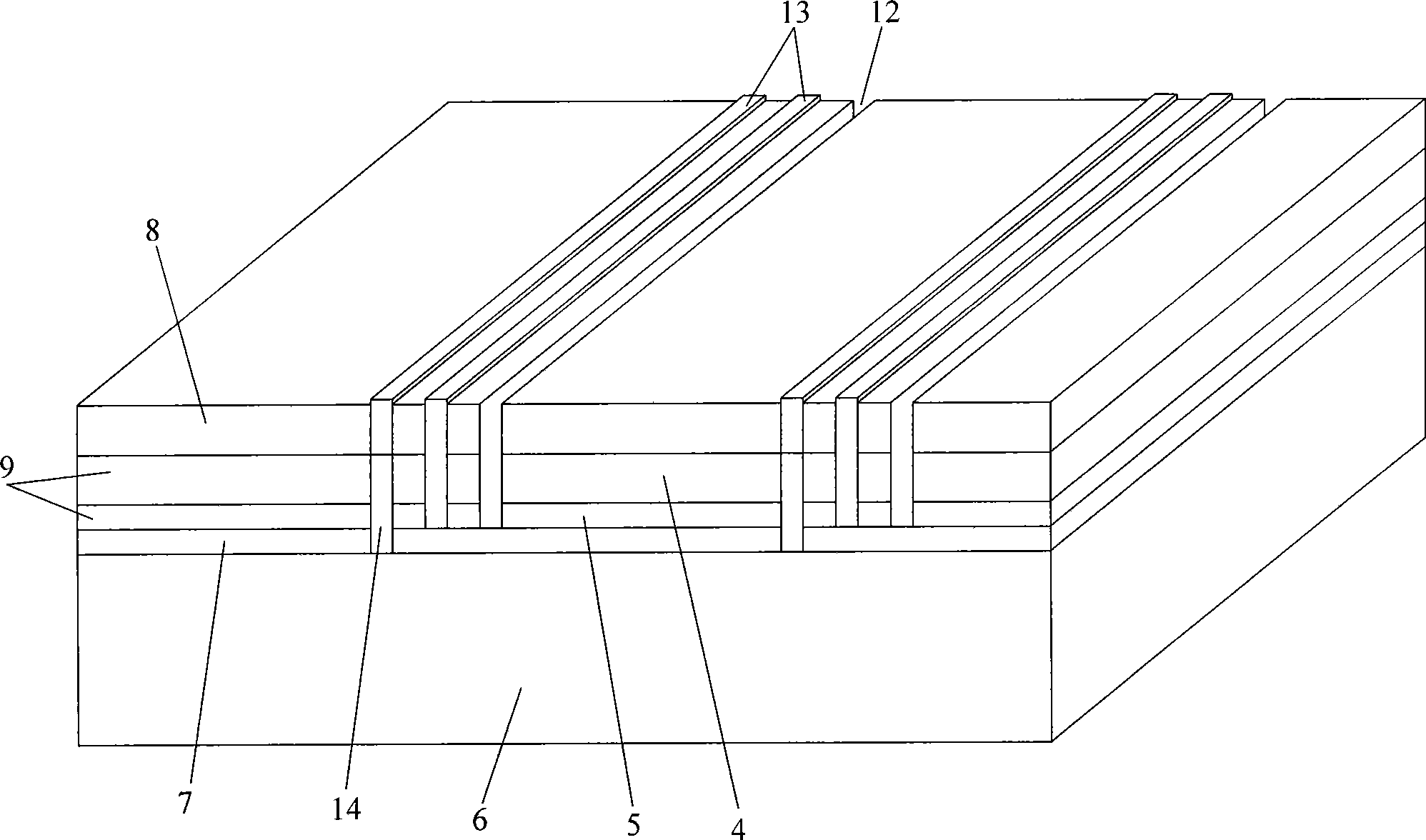

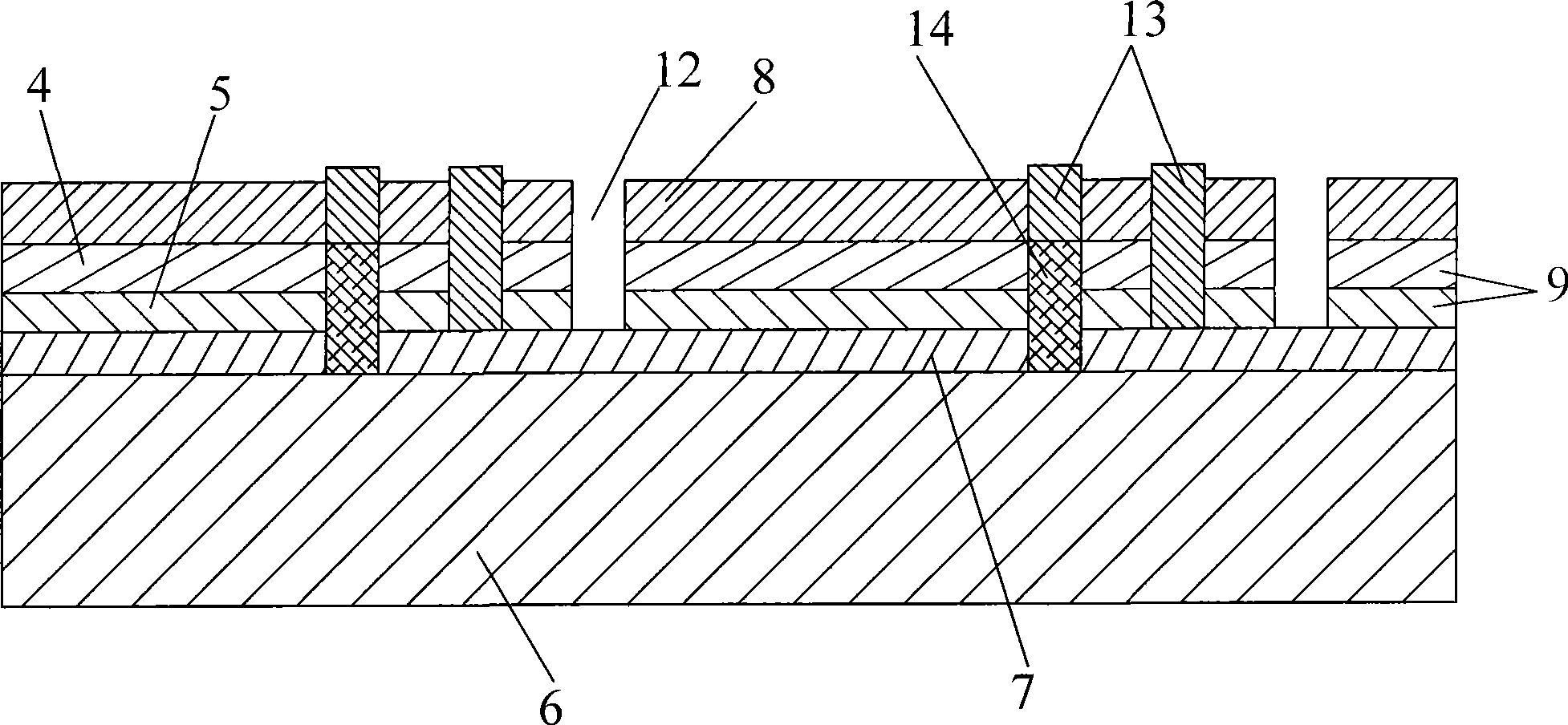

[0035] Example: such as figure 2 with image 3 As shown, a thin-film solar cell module includes a substrate 6 and a working layer disposed on the substrate 6, and the working layer includes a photoconductive film 8, a backlight conductive film 7, and a photoconductive film 8 and a backlight conductive film. The power generation layer 9 between the 7, the power generation layer 9 includes a buffer layer 4 and a semiconductor absorption layer 5, the order of the buffer layer 4 and the semiconductor absorption layer 5 can be replaced, the backlight conductive film 7 is connected to the substrate 6, the Several groups of tangent grooves are provided on the working layer, and each group of tangent grooves includes the fourth tangent groove 10, the fifth tangent groove 11 and the sixth tangent groove 12 distributed in sequence, and the fourth tangent groove 10 cuts off the photoconductive film 8, The power generation layer 9 and the backlight conductive film 7, the fifth tangent g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com