Process for producing phenolic resin and process for producing epoxy resin

一种制造方法、酚树脂的技术,应用在环氧树脂的制造领域,能够解决无法得到固化物、固化时间慢等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0173] Example 1 [Synthesis of Phenol Resin (a-1)]

[0174] In the flask that thermometer, dropping funnel, cooling tube, fractionating tube, stirrer are installed, 2,7-dihydroxynaphthalene represented by 160g (1.0mol) of the following formula is charged,

[0175] [chemical 17]

[0176]

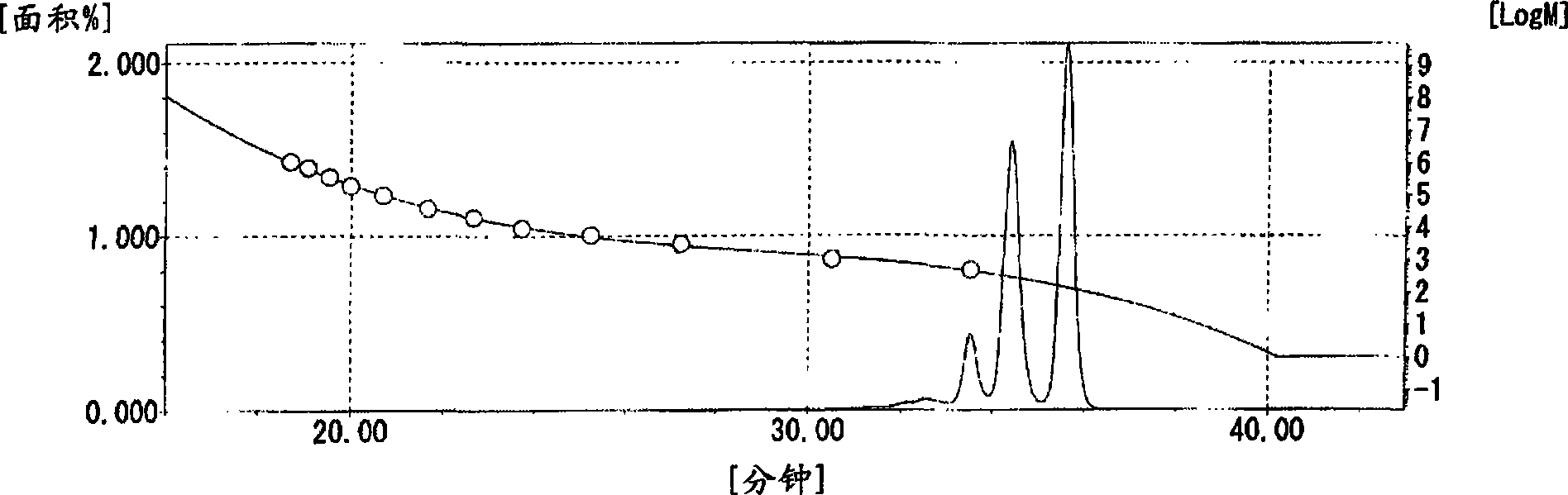

[0177] While blowing in nitrogen gas and stirring, it was heated to 200° C. and melted. After melting, 23 g (0.2 mol) of 48% potassium hydroxide aqueous solution were added. Then, water derived from a 48% potassium hydroxide aqueous solution and generated water were extracted using a fractionating tube, and then reacted for another 5 hours. After the reaction was finished, 1000 g of methyl isobutyl ketone was added, and after dissolving, it was transferred to a separatory funnel. Next, after washing with water until the washing water becomes neutral, the solvent was removed from the organic layer under reduced pressure under heating to obtain 150 g of phenol resin (1). The obtained pheno...

Embodiment 2

[0195] Embodiment 2 [synthesis of phenol resin (a-2)]

[0196] Except changing 160g of 2,7-dihydroxynaphthalene in Example 1 to 160g of 1,6-dihydroxynaphthalene, it carried out similarly to Example 1, and obtained 147g of phenol resin (a-2). The obtained phenol resin (a-2) was a brown solid with a hydroxyl equivalent of 135 g / eq and a melting point of 137°C. From the GPC chart of FIG. 5 , it was confirmed that the remaining rate of the unreacted raw material (1,6-dihydroxynaphthalene) was 24% by area ratio as measured by GPC.

Embodiment 3

[0197] Embodiment 3 [synthesis of phenol resin (a-3)]

[0198] Except changing 160g 2,7-dihydroxynaphthalene in embodiment 1 to 80g (0.5mol) 2,7-dihydroxynaphthalene and 55g (0.5mol) 1,3-dihydroxybenzene, same as embodiment 1 This was carried out to obtain 125 g of phenol resin (a-3). The obtained phenol resin (a-3) was a brown solid with a hydroxyl equivalent of 101 g / eq and a melting point of 136°C. From the GPC chart of FIG. 6 , it was confirmed that the remaining ratio of unreacted raw materials (total of 2,7-dihydroxynaphthalene and 1,3-dihydroxybenzene) was 36% by area ratio as measured by GPC.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com